- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Xinda Machinery

-

Voltage:

-

380V 50Hz

-

Dimension(L*W*H):

-

6400x2200mmx1900mm

-

Weight:

-

4500kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Product name:

-

Jumbo Roll Toilet Tissue Paper Making Machine

-

Working Speed:

-

200-240 m/min

-

Output paper:

-

Toilet Paper Tissue Paper roll

-

Automatic Grade:

-

Full-Automatic

-

Function:

-

Embossing,Rewinding ,Perforating ,Trimming and Cutting

-

Application:

-

Homehold Toilet Paper Rewinding Machine

-

Machine type:

-

Small Toilet Paper Making Machine

-

Usage:

-

Paper Making Mill

-

Raw material:

-

Jumbo Roll Paper

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Saudi Arabia

-

Certification:

-

CE Certificate

Quick Details

-

Type:

-

Slitting Rewinder

-

Production Capacity:

-

200-240 m/min

-

Max. workable width:

-

3000mm

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Xinda Machinery

-

Voltage:

-

380V 50Hz

-

Dimension(L*W*H):

-

6400x2200mmx1900mm

-

Weight:

-

4500kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Product name:

-

Jumbo Roll Toilet Tissue Paper Making Machine

-

Working Speed:

-

200-240 m/min

-

Output paper:

-

Toilet Paper Tissue Paper roll

-

Automatic Grade:

-

Full-Automatic

-

Function:

-

Embossing,Rewinding ,Perforating ,Trimming and Cutting

-

Application:

-

Homehold Toilet Paper Rewinding Machine

-

Machine type:

-

Small Toilet Paper Making Machine

-

Usage:

-

Paper Making Mill

-

Raw material:

-

Jumbo Roll Paper

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Saudi Arabia

-

Certification:

-

CE Certificate

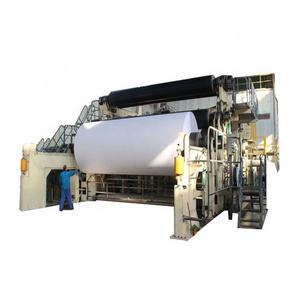

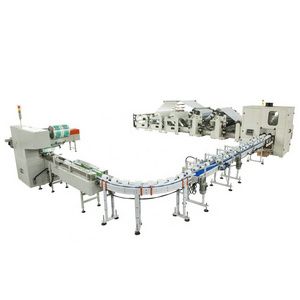

Pulp and Waste Paper Recycling Jumbo Roll Toilet Tissue Paper Making Machine

Product Application

Pulp and Waste Paper Recycling Jumbo Roll Toilet Tissue Paper Making Machine SP-B

this equipment is to perforate and cut the raw paper into various sizes according to the requested.

The finished product is neat, in good order and with equality tension.

It has the feature of compact structure, easy and stable operation, less electricity consumption and covers a small area of 8.4 m². The highest production speed is 120-160m/min.

This equipment is adjustable to meet the requested finished product. This model is the ideal equipment for paper making factory and paper processing factory. This equipment can process raw paper of 1.75m(75B type) in width. There are two types of this model:

A) is ordinary type, it used one embossed unit for 2 ply paper,

B) other is dot-by-dot type, it used embossed units respectally for each one.

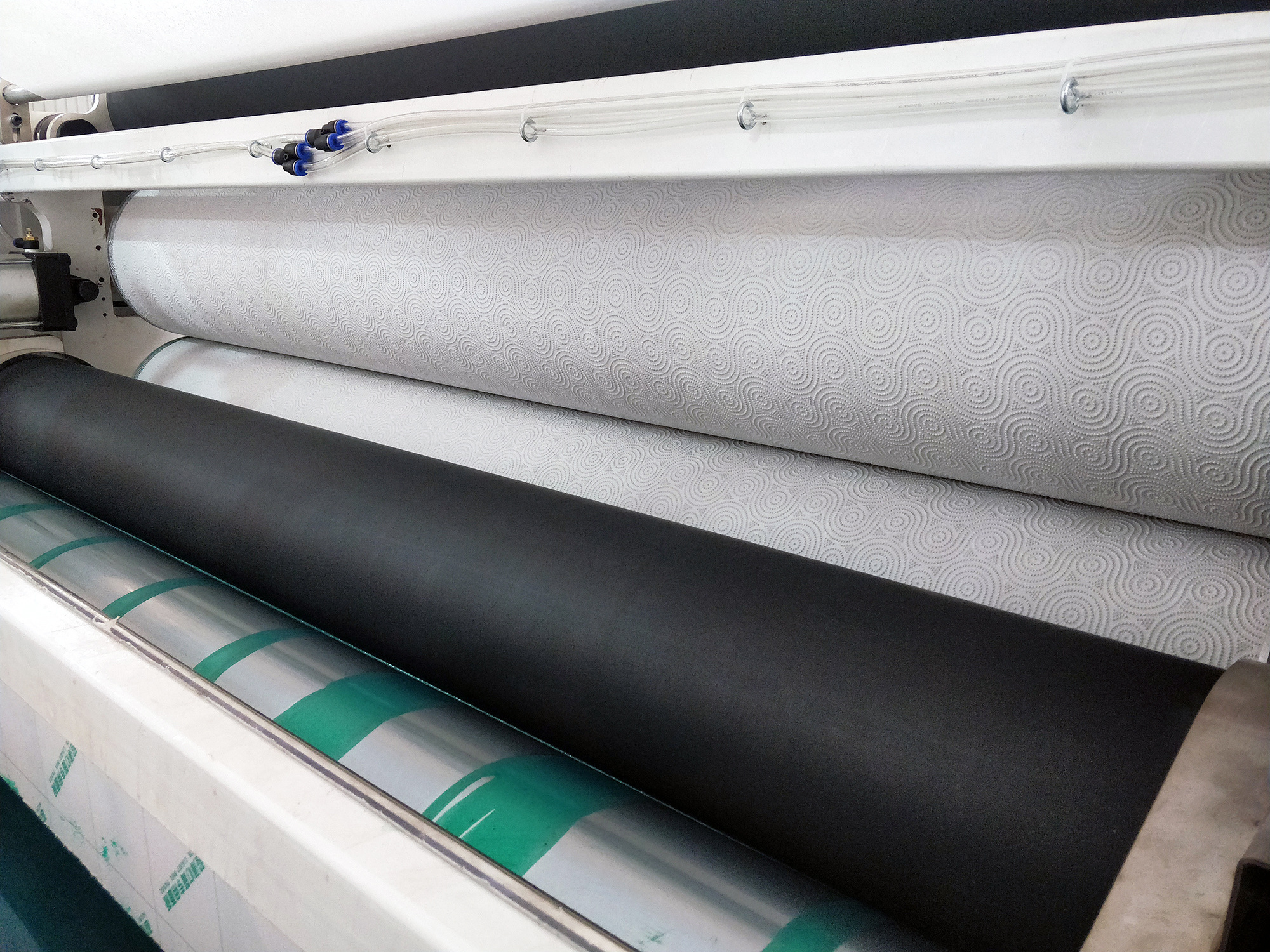

This machine is consist of stand of raw material, paper conveying unit, embossing unit, perforating unit, rolling unit, electricity control and cutting system.

The production process is : unreeling -→ embossing -→perforating-→furl-→slitting

.

Technical data:

1. Production speed: 140-250m /min

2. Power of equipment:5.5kw (380V 50Hz)

3. Maximum diameter of rewinding :130-250mm

Diameter of inner core:40-60mm

4. Overall size(mm): 6200X2750X1800 (LxWxH)

5. Weight : About 3.2T

Specification of raw paper:

1.Width of raw paper:1200MM

2.Diameter of raw paper:700mm-1200mm

3.Thickness of raw paper:14g/m2-20g/ m2 or 38g/m2

4.Diameter of paper core:76mm

You May Also Want the Maxi Roll Production Line

Main Features

1. PLC (computer) control production, degree of full-automatic of production process is high, the function of machine is complete, and production efficiency is high.

2. Load and change the core, spray glue, seal can be done without stop the machine. When changing the core, the machine will low the speed and up the speed automatically.

3. When change the core to rewind, it will be tight first and then loose, to avoid the core loose.

4. Equipped with automatic alarm to indicate filling up of core pipe. The machine will be automatically stopped when there is no core pipes.

5. When raw material broken, the machine will stop automatically.

6. Each raw material unreel separately , equip with tension control.

7. Easy to adjust in order to suitable different paper core.

8. There is tail after the finished product sealed with

9. There is pneumatic jack to load the raw material on machine

As required, the machine can equip with single color or double colors printing device, the pattern is vivid.

The machine can equip with two sets of embossing device according to requirements.

|

Packaging

|

|

|

|

Size

|

3200 (L) * 2000 (W) * 1950 (H)

|

|

|

Weight

|

4.2 T

|

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|