- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YTM

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

2000 KG

-

model:

-

4R3016

-

roller number:

-

4

-

roller diameter:

-

300mm

-

roller height:

-

160mm

-

ring inside diameter:

-

880mm

-

ring height:

-

160mm

-

maximum feed size:

-

15-20mm

-

output size:

-

0.044-0.165mm

-

power of main frame:

-

30000w

-

Product name:

-

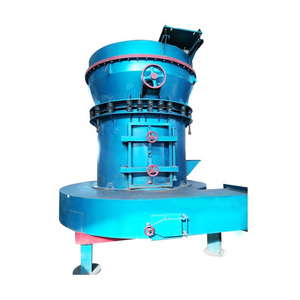

Raymond Grinder

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Capacity(t/h):

-

0.6-2.6

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YTM

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

2000 KG

-

model:

-

4R3016

-

roller number:

-

4

-

roller diameter:

-

300mm

-

roller height:

-

160mm

-

ring inside diameter:

-

880mm

-

ring height:

-

160mm

-

maximum feed size:

-

15-20mm

-

output size:

-

0.044-0.165mm

-

power of main frame:

-

30000w

-

Product name:

-

Raymond Grinder

Small Calcite Raymond Mill Powder Making Machine 3r Stone Grinding Raymond Roller Mill Price lowest price high pressure stone

Raymond grinder(raymond mill) is uesd to grind bartite,calcite,potash feldspar,talcum,marble,limestone,ceram and slag below scale 7 of Moth‘s hardness and 280-odd sorts of non-inflammable and non-explosive stuff in the traded of mining, building material, chemical engineering and metallurgy tor power generation and processing. The product size is adjustable on required in the range of 80-325 meshes.Some of the materials up to 2,500 mesh.

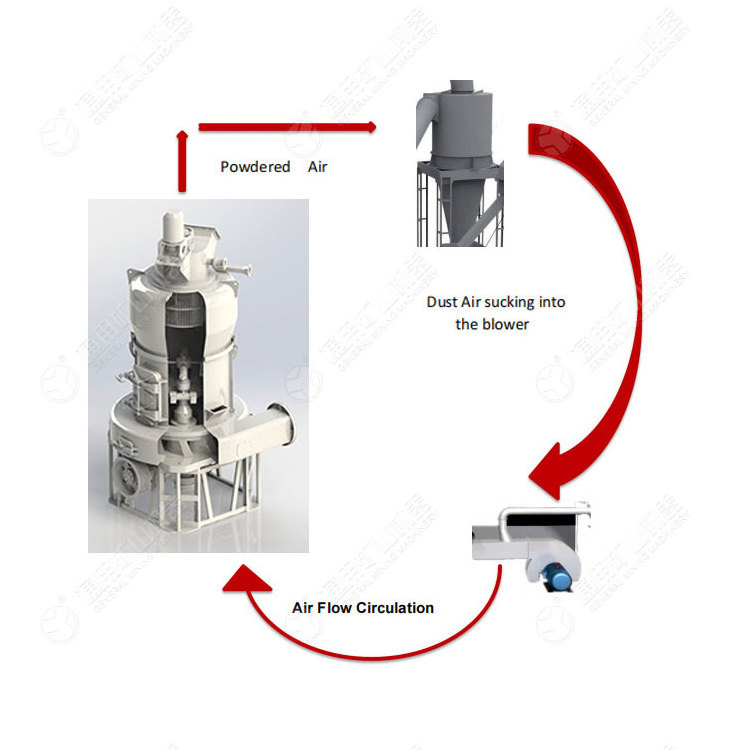

Working process of raymond mill:

the center axis is driven to rotate by the bevel gear and the upper axis end connects with grinding roller hanger where the grinding roller device is placed forming a swinging fulcrum. The grinding roller not only rotates around the central axis but also around the grinding ring, at the same time the grinding roller rotates itself by friction. The blades are placed under the hanger and are in the lower grinding roller end. The rotation of blades and grinding rollers throws materials up to the gap between grinding ring and rollers forming bedding layer which are ground by outward centrifugal force (extrusion force) from grinding roller rotation.

The advantagesof Raymond Grind

1.The finished product has a wide range of particle size and can be adjusted arbitrarily.

2.The dust removal effect is fully in line with the national dust emission standard.

3.The internal grinding device of the mill adopts overlapping multi-stage seal with good sealing performance.

4.The running process of the mill is low noise and stable.

Techinical Parameter

| Model | 3R2715 | 3R3016 | 4R3216 | 5R4121 | ||

| Roller | number | mm | 3 | 3 | 4 | 5 |

| Diameter | 270 | 300 | 320 | 410 | ||

| Height | 150 | 160 | 160 | 210 | ||

| Ring | Inside diameter | 830 | 880 | 970 | 1280 | |

| Height | 150 | 160 | 160 | 210 | ||

| Maximum feedsize (mm) | 15-20 | 15-20 | 20-25 | <30 | ||

| Output size(mm) | 0.044-0.165 | 0.044-0.165 | 0.044-0.165 | 0.95-0.033 | ||

| Power of main frame(mm) | 22 | 30 | 37 | 75 | ||

| Fineness of finalproduct(mm) | 0.125 | capacity (tph) | 2.3-2.8 | 0.6-1.2 | 3.2-4.5 | 6-9.5 |

| 0.075 | 1.8-2.3 | 1.9-2.6 | 2.4-3.1 | 4.5-8 | ||

| 0.044 | 0.9-1.7 | 1-1.9 | 1.8-2.5 | 3-5 | ||

After the crusher crushes the raw materials to the required feeding size, the bucket elevator transports the materials to the hopper. Then the electromagnetic vibrating feeder is evenly sent to the grinding mill. During the corotation of the blade and the grinding roller, the material is shoveled and formed a bedding layer. The material is grinded between the roller and the ring, we get the powder in the end.

The powder is brought to the classifier for powder selection by the air flow of the fan, and the fine powder that meets the fineness requirements enters the large cyclone collector through the pipeline with the air flow, and is separated and collected; The airflow is sucked into the blower by the return air pipe at the upper end of the large cyclone collector. The unsatisfactory powder is thrown by the blade to the outer wall and separated from the airflow, and the coarse powder falls into the grinding chamber for regrinding due to the action of selfgravity. In order to ensure that the mill works under negative pressure, the increased airflow is discharged into the bag filter through the residual pipe between the fan and the main engine, and is discharged into the atmosphere after being purified.

Application field

It is mainly used in the field of metallurgy, building materials, chemicals, mining and such mineral materials for grinding process. This mill can grind materials with Mohs hardness below 9.3 and humidity below 6%, variousnon-tlammable mineral materials, such as quartz, feldspar, calcite, talcum, barite, fluorite, rare earth, marble,ceramics, bauxite, manganese ore, iron ore, copperore, phosphate rock, iron oxide red, Zircon sand, slagand so on.

.

Packing

1).Our crusher machines are packed in plastic bags.

2).The spare parts are packed in wooden cases.

3).Containers are our transport package.

4).Customization can be accepted.

Delievery

We are based on the actual needs of customers,to carry out talloe-made sales.By senior engineer to design scheme,after receipt of customer deposits began production,regardless of the equipment we can deliver the goods in two weeks,delivered the balance after delivery