- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Winner

-

Tolerance:

-

0.001mm

-

Color:

-

White

-

Usage:

-

High Temperature Resistance

-

Size:

-

1-1000mm Custom

-

Feature:

-

Insulation Vacuum

-

Advantage:

-

Professional Technical Support

-

Item:

-

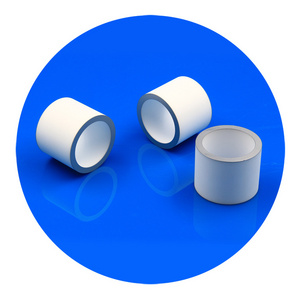

Al2o3 Ceramic Parts

-

MOQ:

-

1-10Pcs

-

Purity:

-

96%

-

Product name:

-

Alumina Ceramic Parts

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Jiangsu, China

-

Model Number:

-

AL-2

-

Brand Name:

-

Winner

-

Tolerance:

-

0.001mm

-

Color:

-

White

-

Usage:

-

High Temperature Resistance

-

Size:

-

1-1000mm Custom

-

Feature:

-

Insulation Vacuum

-

Advantage:

-

Professional Technical Support

-

Item:

-

Al2o3 Ceramic Parts

-

MOQ:

-

1-10Pcs

-

Purity:

-

96%

-

Product name:

-

Alumina Ceramic Parts

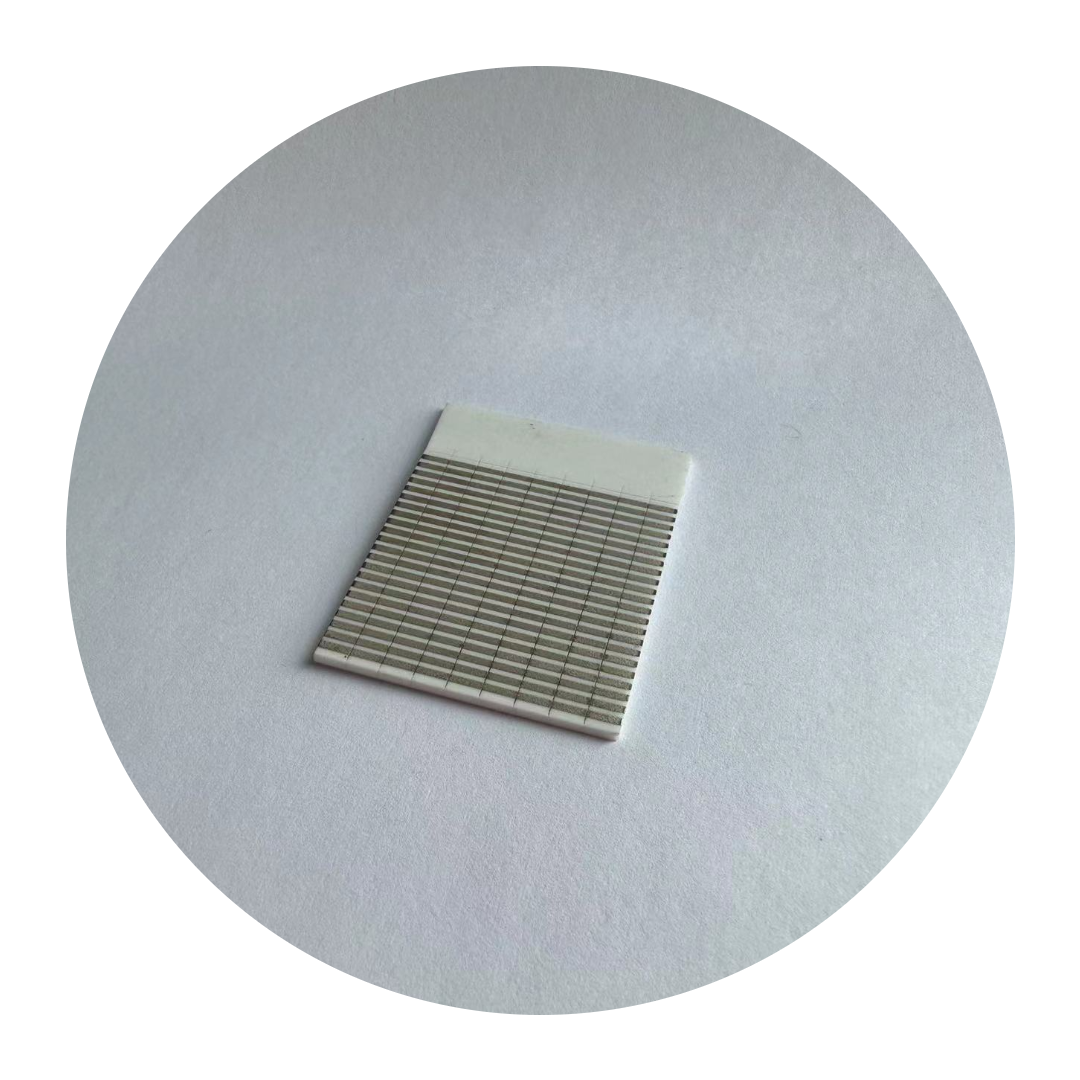

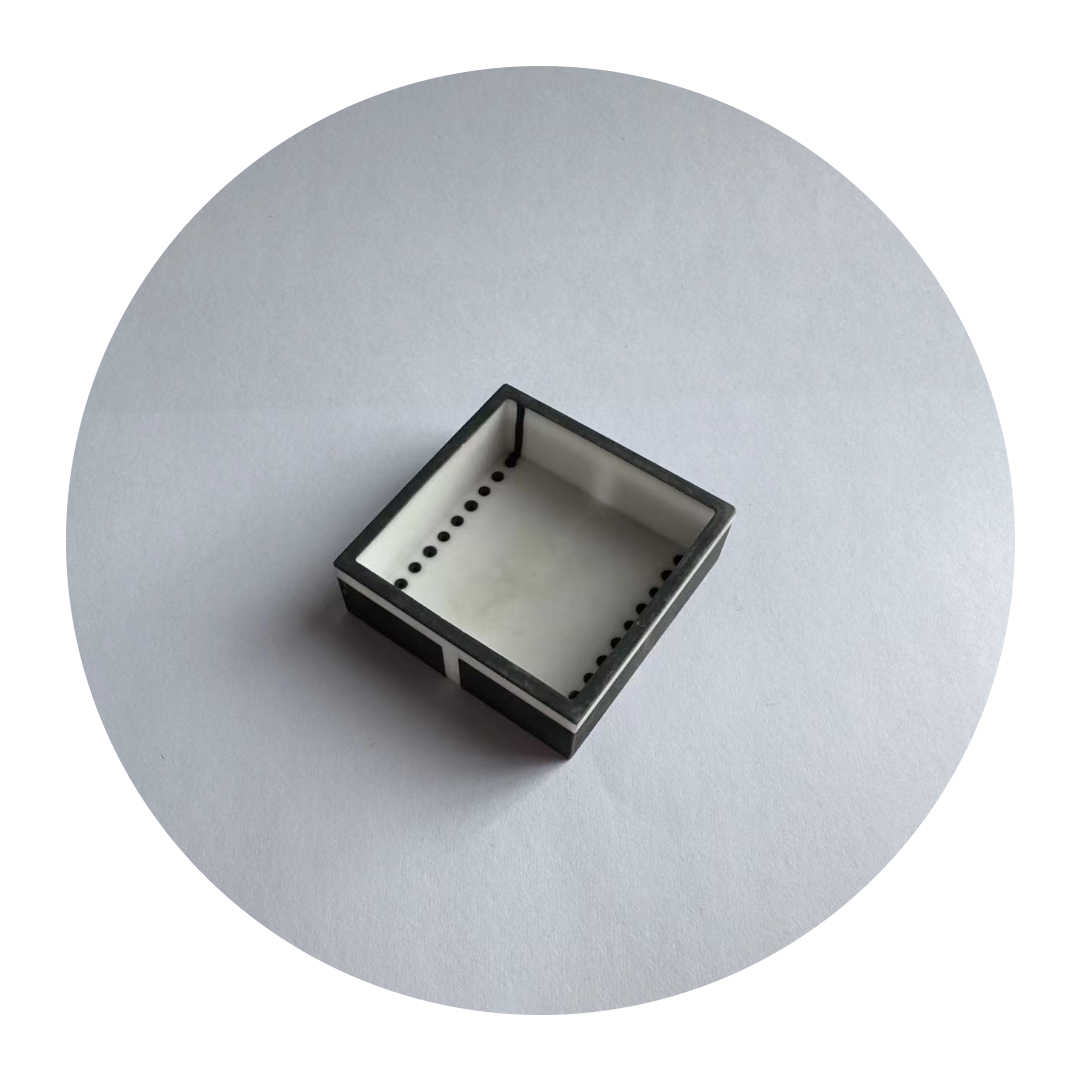

Metallized Ceramic

Indarren metallizes precision ceramic for electronic equipment, vacuum industry applications. The metallized parts are used in critical assemblies brazed by our team. Our metallization creates a strong and robust bond to many different ceramic bodies and has nearly universal applicability for ceramic to metal brazing.

Our ceramic metallization process uses proprietary thick film molybdenum/manganese and molybdenum/manganese/tungsten paints as the base layer on a ceramic substrate. This unique formulation developed and produced entirely in-house enables a hermetic ceramic to metal bond in a brazed assembly.

To prevent oxidation and to improve wettability after the metallization paint is sintered into the ceramic at high temperature, it is plated using either electroless or electrolytic plating or nickel oxide paint. Metallization and nickel thickness is measured using XRF technology to ensure desired thickness specifications are met.

With more than ten years of industry experience, Indarren has expertise in a variety of application methods and is capable of metallizing on flat, cylindrical, and complex ceramic bodies, from prototyping through production.

|

Product Name

|

Metallization of ceramics

|

|

|

|

|

|

|

|

|||||||

|

Material

|

Aluminum , zirconia...Metallization on flat, cylindrical, and complex ceramic bodies

|

|

|

|

|

|

|

|

|||||||

|

Multiple application methods

|

Brush, screen-printing, spray, and needle

|

|

|

|

|

|

|

|

|||||||

|

Size

|

According to drawings or samples

|

|

|

|

|

|

|

|

|||||||

|

Torlerance

|

+/- 0.01mm

|

|

|

|

|

|

|

|

|||||||

|

Vacuum leak

|

testing up to 10-10 Torr

|

|

|

|

|

|

|

|

|||||||

|

Shipping

|

Air Express (DHL/UPS/TNT/ FedEx)

|

|

|

|

|

|

|

|

|||||||

|

Lead time

|

10 - 30 days

|

|

|

|

|

|

|

|

|||||||

|

Properties

|

Units

|

Steatite Ceramic

|

Cordierite Ceramic

|

Mullite Ceramic

|

95% Al₂O₃

|

99% Al₂O₃

|

Zirconia Ceramic

|

Silicon Nitride

|

|

Colour

|

|

White

|

Yellow

|

White

|

White

|

Ivory

|

White

|

Grey

|

|

Density

|

g/cm3

|

2.7

|

1.9

|

2.6

|

3.5

|

3.85

|

6

|

3.2

|

|

Flexural Strength

|

Mpa

|

140

|

30

|

120

|

280

|

340

|

1150

|

600

|

|

Compressive Strength

|

MPa

|

900

|

350

|

500

|

2100

|

2200

|

2500

|

2500

|

|

Max Use Temperature

|

°C

|

1000

|

1200

|

1300

|

1400

|

1650

|

1500

|

1800

|

|

Thermal Condutivity

|

W(m.K)

|

2~3

|

1.3~1.8

|

2~6

|

16~28

|

19~30

|

2.5

|

20

|

|

Thermal Expansion Cofficient

|

10^-6/°C

|

7 ~ 9

|

1.5~3.5

|

5~6

|

6.5~7.5

|

6~8

|

8~10

|

3~4

|

|

ThermalShock Resistance

|

△TC

|

100

|

300

|

150

|

140

|

150

|

250

|

600

|

|

Specific Heat

|

J/kg.K

|

850

|

800

|

900

|

950

|

950

|

500

|

500

|

|

Dielectric Strength

|

KV/mm

|

20

|

—

|

30

|

12

|

10

|

5

|

20

|

|

Dielectric Constant

|

Er

|

6

|

—

|

8

|

9

|

9

|

12

|

6

|

Hot Searches