- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Yantai Hauson

-

Model Number:

-

DN100

-

Surface Treatment:

-

Smooth, Smooth

-

Processing Service:

-

Winding

-

Color:

-

Customized Colors

-

Material:

-

Fibreglass +resin

-

Diameter:

-

DN25mm-DN4000mm

-

pressure rating:

-

0.25 MPa ,0.6 MPa, 1.0 MPa, 1.6 MPa ,2.0 MPa ,2.5MPa

-

inspection standard:

-

JC552

-

Feature:

-

Corrosion Resistance

-

Quality:

-

Guarantee

-

MOQ:

-

1

-

OEM:

-

OEM Service

Quick Details

-

Application:

-

water supplying, Civil water supplying

-

Technique:

-

Winding

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Yantai Hauson

-

Model Number:

-

DN100

-

Surface Treatment:

-

Smooth, Smooth

-

Processing Service:

-

Winding

-

Color:

-

Customized Colors

-

Material:

-

Fibreglass +resin

-

Diameter:

-

DN25mm-DN4000mm

-

pressure rating:

-

0.25 MPa ,0.6 MPa, 1.0 MPa, 1.6 MPa ,2.0 MPa ,2.5MPa

-

inspection standard:

-

JC552

-

Feature:

-

Corrosion Resistance

-

Quality:

-

Guarantee

-

MOQ:

-

1

-

OEM:

-

OEM Service

Filament wound fiberglass reinforced plastic grp underground sewer pipe sizes

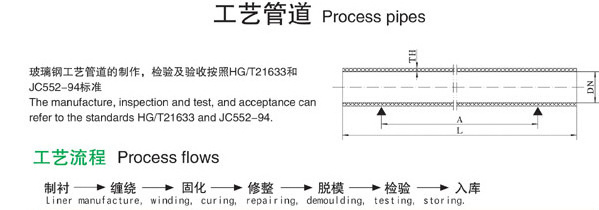

FRP Process Pipeline

Main molding process:

Our company adopts the computer-controlled continuous glass fiber winding molding process. According to the design procedure, the inner lining layer, the structure layer, and the outer protective layer are sequentially made on the core mold. The heat treatment is carried out through the far-infrared baking sheet. The flame retardant ,anti-aging agent or various color pastes can be added according to user requirements.

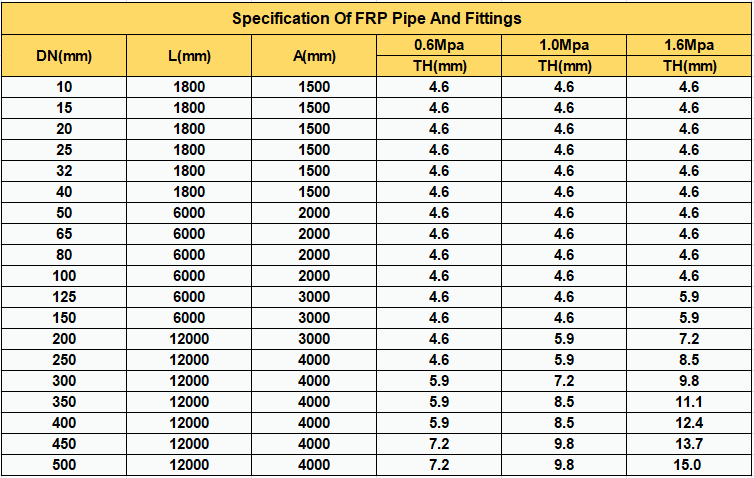

Product specifications

(1) Diameter: DN25mm-DN4000mm

(2) Pressure rating: 0.25 MPa, 0.6 MPa, 1.0 MPa, 1.6 MPa, 2.0 MPa, 2.5MPa, according to the special requirements of users, higher pressures can reach more than 6Mpa.

(3) Single length: 1m, 3m, 6m, 9m, 12m. Note: Pipes with other pressure grades and length specifications can also be produced according to user requirements.

Connection method

Double "O" type sealing ring socket connection, single "O" type sealing ring socket connection, butt joint and socket bonding, flange connection, etc.

1.Good corrosion resistance and long service life

FRP pipes can resist the long-term erosion of various acids, alkalis, salts, organic solvents, sea water, sewage and other chemical media. Pipes with different performance can be selected according to different media types and operating temperatures.

2.Excellent mechanical properties

FRP pipes have low specific gravity (1.8~2.1g/cm3) and high strength (≥300MPa), and their specific strength is much greater than steel pipes and cast iron pipes.

3.Excellent hydraulic performance

The inner surface of the FRP pipe is very smooth and the friction resistance is small (n≤0.0084), which can obviously reduce the pressure loss along the way and increase the flow rate. Under the same flow rate, a smaller pipe diameter or a smaller power delivery pump can be selected. Thereby reducing the initial investment of the project and saving energy consumption (reducing operating costs).

4.Good designability and wide adaptability

The material selection, winding angle and layer design can be changed to adapt to different working pressure, medium, rigidity (or embedding depth) requirements, so as to make FRP pipes with different pressure levels and special properties.

5.Anti-fouling, non-toxic

Pipes made of food-grade resin can be used to transport drinking water.

6.Few joints, good sealing

The length of a single FRP pipe is generally 12 meters, and it is connected by a double "O" type sealing ring. Each interface can be pressure tested and the sealing is reliable. Low penetration-exudation rate: Due to the good sealing connection and longer pipe length, FRP pipes have a lower penetration-exudation rate than traditional materials, which greatly reduces the leakage of groundwater into the pipeline and also reduces the pollution of soil and groundwater by media seepage.