- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Chemical Industry

-

Description:

-

Solid-liquid Separation Machine

-

Function:

-

Screening\separation\sorting\sieving

-

Operation:

-

Batch

-

Motor:

-

Explosion-proof Motor

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Yhchem

-

Weight:

-

280 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Chemical Industry

-

Description:

-

Solid-liquid Separation Machine

-

Function:

-

Screening\separation\sorting\sieving

-

Operation:

-

Batch

-

Motor:

-

Explosion-proof Motor

-

Certification:

-

CE

Product Parameter

|

Model

|

YFT-2

|

YFT-5

|

YFT-10

|

YFT-20

|

YFT-50

|

YFT-100

|

|||||

|

Tower kettle volume (L)

|

2

|

5

|

10

|

20

|

50

|

100

|

|||||

|

Tower height (m)

|

1

|

0.1

|

2

|

|

|

|

|||||

|

Condensing area (m²)

|

0.2

|

15

|

0.5

|

|

0.8

|

|

|||||

|

Reflux ratio control

|

YES

|

|

|

|

|

|

|||||

|

Temp pressure display

|

YES

|

|

|

|

|

|

|||||

|

Continuous sampling

|

YES

|

|

|

|

|

|

|||||

|

Working temperature range (℃)

|

-20~200

|

|

|

|

|

|

|||||

Product Description

The lab and pilot scale distillation column are made of stainless steel,and can be designed for normal, reduced and pressurized use. The tower kettle can be designed with electric heating, transfer oil heating. steam heating and other heating methods. The specifications of the tower section are 38-200 mm and the height is 0.5-8.0 m. Each section of the tower section can be equipped with a feed port temperature measurement port, and various non-standard products can also be designed and manufactured according to the specific requirements of customers. Modern intelligent instruments are used to set the temperature of the tower body to compensate the heat, so that the experimental process is closer to the ideal state to a great erextent and achieves better experimental results.

Rroduct Advantage

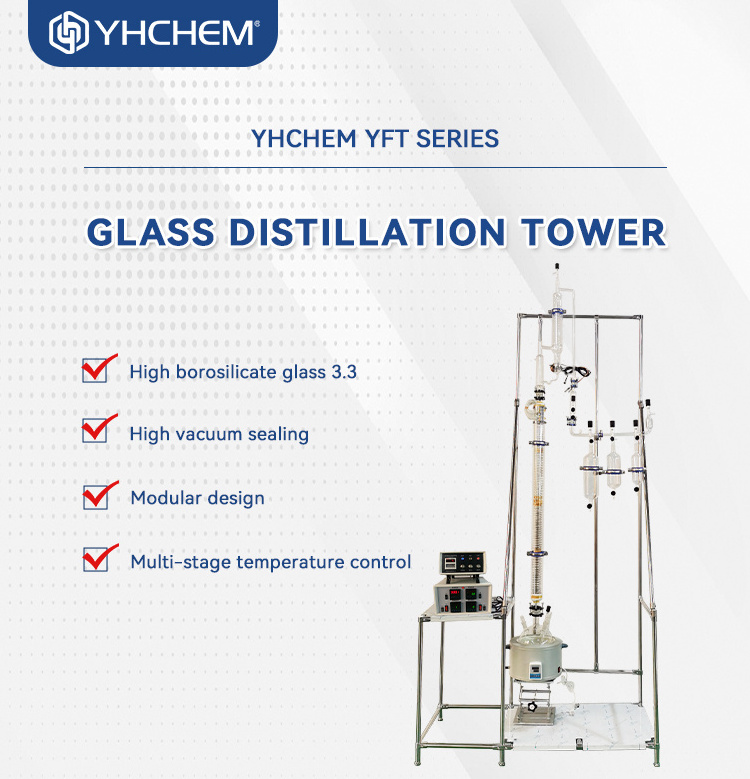

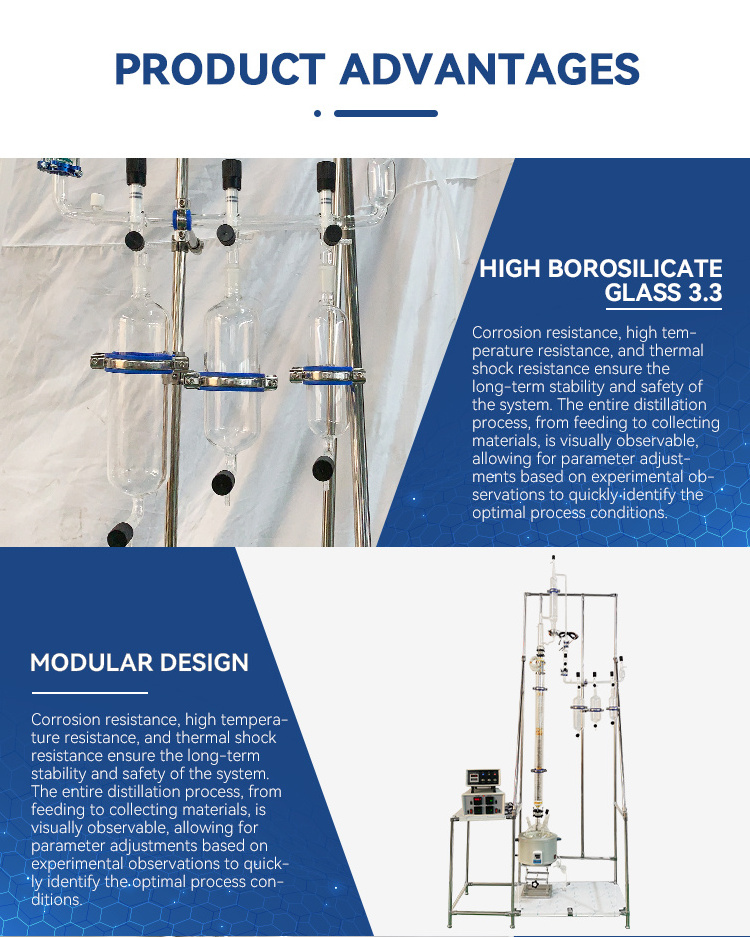

♣1.HIGH BOROSILICATE GLASS 3.3

Corrosion resistance, high temperature resistance, and thermal shock resistance ensure the long-term stability and safety of the

system.The entire distillation process from feeding to collecting materials is visually observable, and parameters can bead justed based on experimental observations to quickly find the optimal process conditions.

♣2.MODULAR DESIGN

Flexible replacement of configuration components or upgrades, compact structure, easy disassembly and maintenance, reduce costs

♣3.HIGH VACUUM SEALING METHOD

Effectively reduce the distillation tmperature and reduce energy consumption

♣4.MULTI-STAGE TEMPERATURE CONTROL

Flexible design of distillation conditions

Corrosion resistance, high temperature resistance, and thermal shock resistance ensure the long-term stability and safety of the

system.The entire distillation process from feeding to collecting materials is visually observable, and parameters can bead justed based on experimental observations to quickly find the optimal process conditions.

♣2.MODULAR DESIGN

Flexible replacement of configuration components or upgrades, compact structure, easy disassembly and maintenance, reduce costs

♣3.HIGH VACUUM SEALING METHOD

Effectively reduce the distillation tmperature and reduce energy consumption

♣4.MULTI-STAGE TEMPERATURE CONTROL

Flexible design of distillation conditions

Application Fields

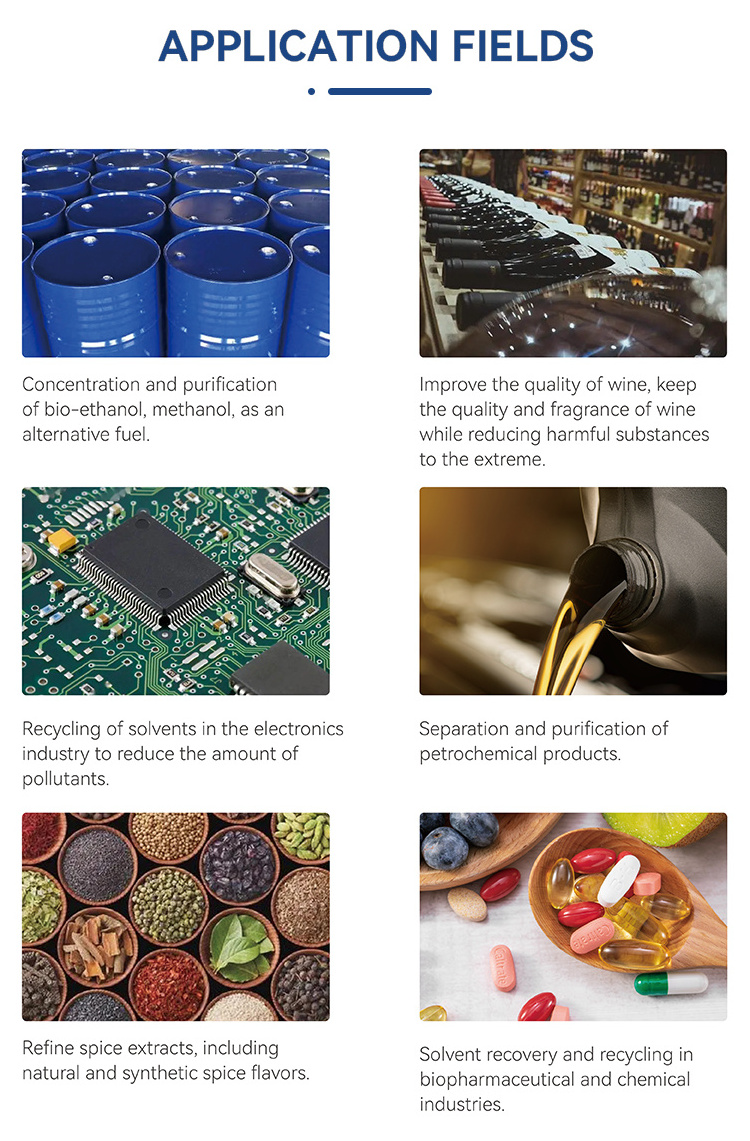

♣1.Concentration and purification of bio-ethanol. methanol, as analternative fuel.

♣2.Improve the quality of wine, keep the quality and fragrance of wine while reducing harmful substances to the extreme.

♣3.Recycling of solvents in the electronics industry to reduce the amount of pollutants.

♣4.Separation and purification of petrochemical products.

♣5.Refine spice extracts, including natural and synthetic spice flavors.

♣6.Solvent recovery and recycling in biopharmaceutical and chemical industries.

♣2.Improve the quality of wine, keep the quality and fragrance of wine while reducing harmful substances to the extreme.

♣3.Recycling of solvents in the electronics industry to reduce the amount of pollutants.

♣4.Separation and purification of petrochemical products.

♣5.Refine spice extracts, including natural and synthetic spice flavors.

♣6.Solvent recovery and recycling in biopharmaceutical and chemical industries.

Support Customisation

Can be customized according to customer's requirement.

♣ 1.Collection bottle design

♣ 2.Tower column insulation design

♣ 1.Collection bottle design

♣ 2.Tower column insulation design

Product Structure

♣1. Distillation head

♣2. Vacuum sampler

♣3. Distillation column

♣4. Sample spliter

♣5. Digital display vacuum gauge (optional)

♣6. Reflux ratio controller

♣7. Tower temperature controller

♣8. The tower kettle

♣9. Heating mantle

♣10. Lifting platform

♣2. Vacuum sampler

♣3. Distillation column

♣4. Sample spliter

♣5. Digital display vacuum gauge (optional)

♣6. Reflux ratio controller

♣7. Tower temperature controller

♣8. The tower kettle

♣9. Heating mantle

♣10. Lifting platform

Supported Equipment

♣1.Cooling circulator

♣2.Rotary vane vacuum pump

♣2.Rotary vane vacuum pump

Product Series

♣1.Stainless Still Distillation Tower

♣2.Thin Film Distillation Column

♣2.Thin Film Distillation Column

Hot Searches