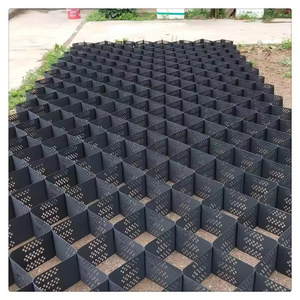

Geocell is three dimensional, honeycomb like structures manufactured from high density polyethylene and jointly welded by

ultrasonic technique. It is flexible to fold during the transport and installation on construction site. The geocell nets will be filled with soils, granular, cements or other on-site infill materials when stretched into web structures, which has powerful and rigid confinement in the lateral and vertical sides.

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

slope protection

-

Design Style:

-

Industrial

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Dingkun

-

Model Number:

-

Dk-geocell

-

Product name:

-

HDPE Geocell

-

Welding distance:

-

330mm-1000mm

-

Height:

-

50mm-300mm

-

MOQ:

-

500square Meters

-

Peel strength of welding point::

-

1000~1420N/10CM

-

Tensile Strength:

-

20.0Mpa

-

Surface:

-

Textured Perforated Smooth Unperforated

-

Raw Material:

-

HDPE PP

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support, Free spare parts

-

Project Solution Capability:

-

Cross Categories Consolidation

-

Application:

-

slope protection

-

Design Style:

-

Industrial

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Dingkun

-

Model Number:

-

Dk-geocell

-

Product name:

-

HDPE Geocell

-

Welding distance:

-

330mm-1000mm

-

Height:

-

50mm-300mm

-

MOQ:

-

500square Meters

-

Peel strength of welding point::

-

1000~1420N/10CM

-

Tensile Strength:

-

20.0Mpa

-

Surface:

-

Textured Perforated Smooth Unperforated

-

Raw Material:

-

HDPE PP

Products Description

Specification

|

Materials Properties

|

Unit

|

Index

|

|

|

|

|

|

Test Method

|

|||||

|

Cell Depth

|

mm

|

50

|

75

|

100

|

150

|

200

|

250

|

|

|||||

|

Welding space

|

mm

|

330/356/400/445/450/500/600/660/712/800

|

|

|

|

|

|

|

|||||

|

Polymer Density

|

g/cm3

|

0.935-0.965

|

|

|

|

|

|

ASTM D 1505

|

|||||

|

Environmental Stress Crack Resistance

|

Hours

|

>400

|

|

|

|

|

|

ASTM D 5397

|

|||||

|

Environmental Stress Crack Resistance

|

Hours

|

6000

|

|

|

|

|

|

ASTM D 1693

|

|||||

|

Carbon Black Content

|

%

|

1.5-2.0

|

|

|

|

|

|

ASTM D 1603

|

|||||

|

Oxidative Induction Time

|

Min

|

≥150

|

|

|

|

|

|

ASTM D 5885

|

|||||

|

Nominal Sheet Thickness After Texturing

|

mm

|

≥1.52

|

|

|

|

|

|

ASTM D 5199

|

|||||

|

Yield Strength

|

kn/m

|

20

|

|

|

|

|

|

ASTM D 6693

|

|||||

|

Resistance to breakage

|

kn/m

|

12

|

|

|

|

|

|

ASTM D 6693

|

|||||

|

Elongation at the fluenca

|

%

|

12

|

|

|

|

|

|

ASTM D 6693

|

|||||

|

Elongation at break

|

%

|

100

|

|

|

|

|

|

ASTM D 6693

|

|||||

|

Tear Resistance

|

N

|

155

|

|

|

|

|

|

ASTM D 1004

|

|||||

|

Strip Puncture Resistance

|

N

|

450

|

|

|

|

|

|

ASTM D 4833

|

|||||

|

Resistance of joints to peel off

|

kn/m

|

10

|

|

|

|

|

|

EN ISO13426-1B

|

|||||

|

Seam peel strength

|

N

|

710

|

1065

|

1420

|

2130

|

2840

|

3550

|

EN ISO13426-1B

|

|||||

|

Seam Efficiency

|

%

|

100

|

|

|

|

|

|

GRI-GS13

|

|||||

|

Nominal Expanded Cell Size (width x length )

|

mm

|

244x205,333x280,527x442,etc

|

|

|

|

|

|

|

|||||

|

Nominal Expanded panel Size (width x length)

|

m

|

2.44x6.15, 5.0x7.0,5.8x11.05, etc

|

|

|

|

|

|

|

|||||

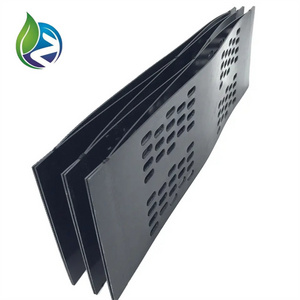

Sheet thickness:

(1) 1.5mm~1.7mm for textured perforated geocell

(2) 1.0mm~1.2mm for flat surface geocell

(1) 1.5mm~1.7mm for textured perforated geocell

(2) 1.0mm~1.2mm for flat surface geocell

Product Feature

Application

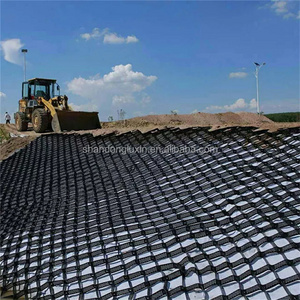

1. Used for all kinds of road building, driveways, soil stabilization and embankment stabilization

2. Used to stabilize river embankments.

3. Used to prevent landslides.

4. Using Geocell construction can greatly reduce labor intensity and reduce the thickness of the roadbed, construction speed, good performance and greatly reduce the project cost.

2. Used to stabilize river embankments.

3. Used to prevent landslides.

4. Using Geocell construction can greatly reduce labor intensity and reduce the thickness of the roadbed, construction speed, good performance and greatly reduce the project cost.

Hot Searches