- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

TSBSC4C006

-

Product name:

-

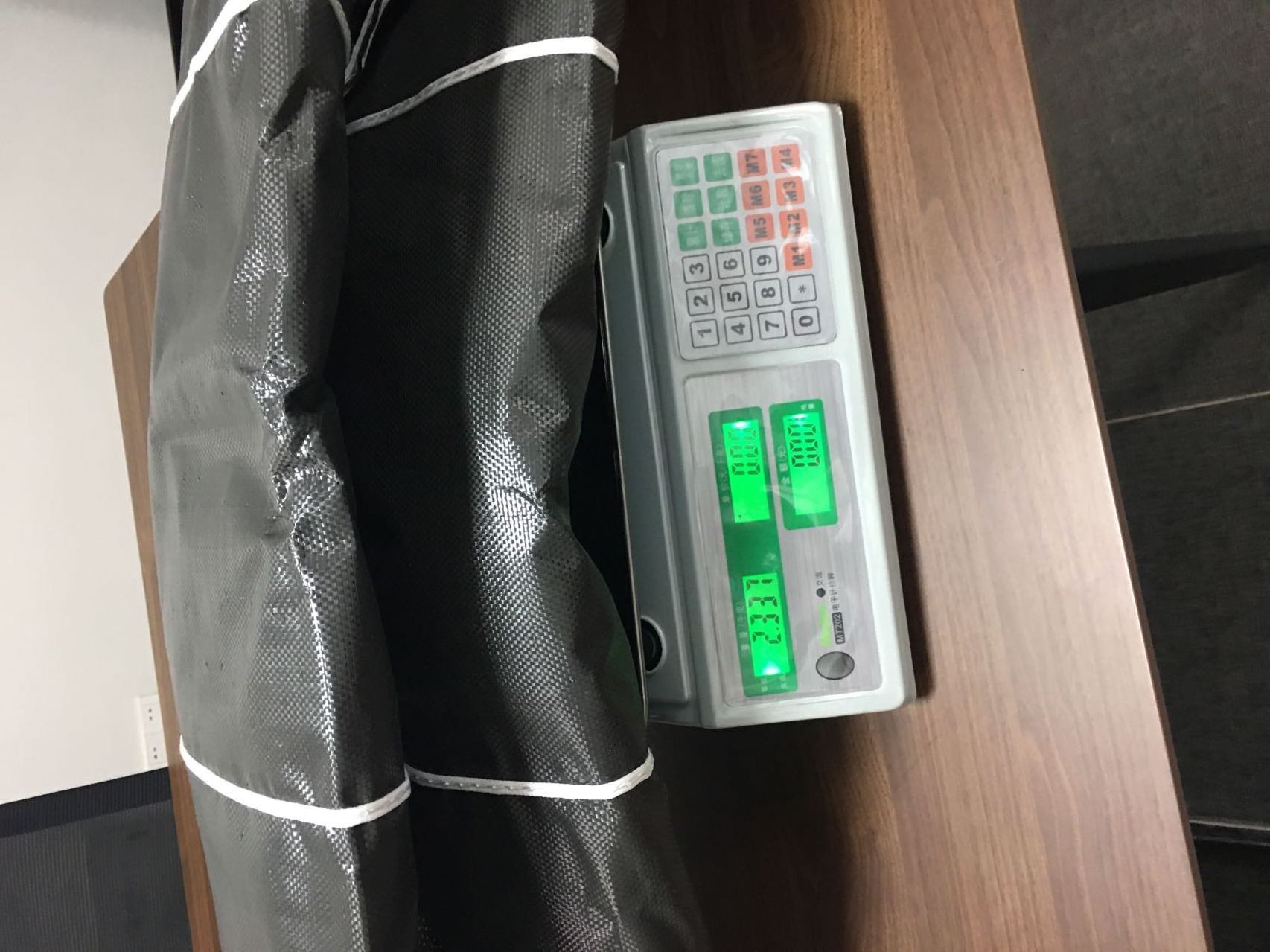

Carbon Black Jumbo Bag for Biochar Charcoal Bitumen

-

Type of bag:

-

Circular Jumbo Bag

-

Material:

-

100% Virgin Polypropylene

-

Color:

-

Black

-

MOQ:

-

500

-

Size:

-

90 * 90 * 110 cm; As Customized

-

Logo:

-

Accept Customized Logo Printing

-

OEM:

-

Accecptable

-

Certificate:

-

ISO9001:2015, ISO14001:2015, ISO45001:2018, ISO:21898

-

Baffle:

-

With Baffles/ Without Baffles

Quick Details

-

Feature:

-

Breathable

-

Loading Weight:

-

500kg, 1000kg, 1500kg, 2000kg

-

Place of Origin:

-

Shanxi, China

-

Model Number:

-

TSBSC4C006

-

Product name:

-

Carbon Black Jumbo Bag for Biochar Charcoal Bitumen

-

Type of bag:

-

Circular Jumbo Bag

-

Material:

-

100% Virgin Polypropylene

-

Color:

-

Black

-

MOQ:

-

500

-

Size:

-

90 * 90 * 110 cm; As Customized

-

Logo:

-

Accept Customized Logo Printing

-

OEM:

-

Accecptable

-

Certificate:

-

ISO9001:2015, ISO14001:2015, ISO45001:2018, ISO:21898

-

Baffle:

-

With Baffles/ Without Baffles

Product Description

|

Product Features

|

|

|

|

Product name

|

FIBC 1 Ton Bags Carbon Black Jumbo Bag for Biochar Charcoal Bitumen Waterproof Baffle Big Bag

|

|

|

Type

|

Circular, Breathable

|

|

|

Size

|

90 * 90 * 110 cm; Accept Customized

|

|

|

Material

|

100% Virgin PP

|

|

|

Loops

|

4 Cross Corner Soft Loops Belt, Height 30cm/Tailor-made

|

|

|

Useage

|

Biochar Charcoal Asphalt Container Big Bag

|

|

|

SWL

|

1000KG, 500KG, 1500KG, 2000KG

|

|

|

SF

|

5:1/3:1/6:1

|

|

Detailed Images

Company Introduction

HAOYU TRADE mainly deals in packaging, refractory, abrasives, alloy and other products. The company is devoted to fulfill the needs of distributors and end customers worldwide with the best product quality and comprehensive service.

Exhibition

FAQ

1. Can fiber reinforced composites be reused?

Under certain conditions, the bags can be reused. The bag must be designed and rated for multiple purposes. To reuse the bags, they must have a Safety Factor Ratio (sfr) of 6:1.

2. What is the coating or laminate in bulk bags?

The liner, also known as a laminate, is an additional polypropylene film that is added to the bag fabric to seal small gaps in the polymeric knit fabric. The film can be added inside or outside the bag.

Liners/laminates can also be used as moisture proof layers. For some uses, polyethylene liner is a better option to protect contents. Neither the liner nor the liner makes the bag 100% waterproof.

3. How can we guarantee the quantity?

Pre-production samples are always provided before mass production;

Always perform final inspection before shipment;

4. How many times will the sample be completed? What is the production scale of your factory?

Sample preparation time is usually 2-4 days.

The lead time of mass production will depend on the quantity, quality and existing orders.

5. Do you have inventory for sale?

No, We process OEM orders, which means the size, material quantity, packing solution, etc. will depend on your needs.

Under certain conditions, the bags can be reused. The bag must be designed and rated for multiple purposes. To reuse the bags, they must have a Safety Factor Ratio (sfr) of 6:1.

2. What is the coating or laminate in bulk bags?

The liner, also known as a laminate, is an additional polypropylene film that is added to the bag fabric to seal small gaps in the polymeric knit fabric. The film can be added inside or outside the bag.

Liners/laminates can also be used as moisture proof layers. For some uses, polyethylene liner is a better option to protect contents. Neither the liner nor the liner makes the bag 100% waterproof.

3. How can we guarantee the quantity?

Pre-production samples are always provided before mass production;

Always perform final inspection before shipment;

4. How many times will the sample be completed? What is the production scale of your factory?

Sample preparation time is usually 2-4 days.

The lead time of mass production will depend on the quantity, quality and existing orders.

5. Do you have inventory for sale?

No, We process OEM orders, which means the size, material quantity, packing solution, etc. will depend on your needs.

Hot Searches