- Product Details

- {{item.text}}

Quick Details

-

Max. Blank Diameter:

-

5mm

-

Max. Blank Length:

-

50mm

-

Die Diameter:

-

34.5x80

-

Blank Per Max:

-

175pcs

-

1st Punch Die:

-

31x75.5

-

Shear Die:

-

19

-

Cutting Knife Diameter:

-

9

-

Main Motor:

-

2.2

-

Dimension:

-

190x105x125

Quick Details

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Lituo

-

Weight (KG):

-

1750

-

Max. Blank Diameter:

-

5mm

-

Max. Blank Length:

-

50mm

-

Die Diameter:

-

34.5x80

-

Blank Per Max:

-

175pcs

-

1st Punch Die:

-

31x75.5

-

Shear Die:

-

19

-

Cutting Knife Diameter:

-

9

-

Main Motor:

-

2.2

-

Dimension:

-

190x105x125

Products Description

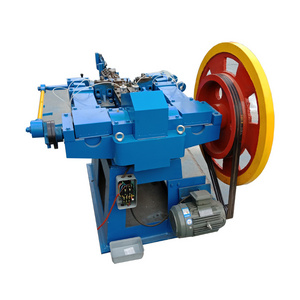

Hot product roofing screw manufacturing making machine screw product machine for factory

Functions of heading machine:

(1). The machine belong to the cold heading machine, the function is the first molding and the second punching products, which is mainly used for forming the heads of the screw products, the work principle is line materials calibration, accessing lines, sending materials to the main mold, first punching initial forging, and second punching the formed blank materials and withdraw. The work gets done without any letup, the production capacity can be up to about 150-200pcs per minute, which belongs to the more advanced products in the current technology.

(2). The machine can make the common products such as the common self-tapping screw, electric screw, micro-screw, socket head cap

bolts, self drilling screw, fiber plate screw etc. For an example PKO can upsetter other non standard abnormal hardware and metal

products.

bolts, self drilling screw, fiber plate screw etc. For an example PKO can upsetter other non standard abnormal hardware and metal

products.

(3). Upsetter various materials: Common steel, carbon steel, stainless steel, copper, aluminum, and alloy steel etc with widely functions. (For the stainless steel and alloy steel, can heat them to the appropriate temperature with the heater, and can upsetter.)

The heading machine can manufacture

self-tapping screws, mini screws, internal and hexagon screw, self-drilling screws, chipboard screws

and

other common products

.

PRODUCT SPECIFICATIONS

|

Max. Blank Diameter

|

4mm, 5mm, 6mm, 8mm

|

|

Max. Blank Lengt

|

30mm, 40mm, 50mm, 60mm, 63mm, 76mm, 85mm, 100mm, 120mm, 127mm

|

|

Die Diameter

|

ᶲ34.5x50

|

|

1st/2nd Punch Die

|

ᶲ25x60; ᶲ25x50

|

|

Shear Die

|

15, 19, 25, 28

|

|

Cutting Knife Diameter

|

9, 10, 12

|

|

Main Motor

|

1.5 / 2.2 / 3.0 / 4.0 / 5.5 / 7.5kw

|

|

Blank Per Max

|

160-190pcs

|

|

Size(L*W*H)

|

170/190x105x120, 215x110x125, 220/250x120x130

|

|

Weight

|

1380 / 1580 / 1680 / 1750 / 1850 / 1980

|

|

Dimension

|

220x120x130; 280x140x150

|

Product packaging

Product Show

FAQ

1. Why do customers choose to cooperate with us?

Our company has many years of production experience, with superior quality and good after-sales service.

2. How long does it take to respond to customer inquiries?

We have multiple online business people, the response is usually <2 hours

3. How do we control product quality? What is the satisfaction of after-sales service?

We will guarantee the quality of the machine, and perform a second test on the machine before leaving the warehouse to ensure that each set of equipment runs well, and provide long-term after-sales service to 100% customer satisfaction.

4. How is your after-sale service?

We have a professional technology supporting team for your timely services. You can get the help you need in time by telephone, webcam, online chat (Google talk, Facebook, Skype). Please contact us once the machine has any problem. Best service will be offered.

5. Do you offer spare parts?

For the spare parts, we will supply the parts for free during one year guarantee period, also the parts supplying at original cost after that.

Hot Searches