- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380V

-

Dimension(L*W*H):

-

890*680*1330mm

-

Power (kW):

-

11

-

Weight (KG):

-

180 KG

-

Product Name:

-

Polyurethane Spray Machine

-

Application:

-

Spray Wall

-

Name:

-

Pu Gasket Making Machine

-

Raw material:

-

Polyurethane Material A+B

-

Color:

-

Customised

-

Foam Type:

-

Trough

-

Power source:

-

3 Phase 380V 50Hz

-

Air source:

-

0.5-0.8Mpa 0.9m3/min

-

Raw Output:

-

2~12 Kg/min

-

Driven mode:

-

Pheumatic

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUGONG

-

Machine Type:

-

foaming machine

-

Voltage:

-

220/380V

-

Dimension(L*W*H):

-

890*680*1330mm

-

Power (kW):

-

11

-

Weight (KG):

-

180 KG

-

Product Name:

-

Polyurethane Spray Machine

-

Application:

-

Spray Wall

-

Name:

-

Pu Gasket Making Machine

-

Raw material:

-

Polyurethane Material A+B

-

Color:

-

Customised

-

Foam Type:

-

Trough

-

Power source:

-

3 Phase 380V 50Hz

-

Air source:

-

0.5-0.8Mpa 0.9m3/min

-

Raw Output:

-

2~12 Kg/min

-

Driven mode:

-

Pheumatic

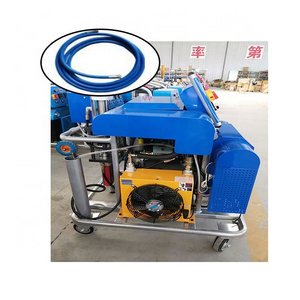

High Pressure Polyurethane Spraying Equipment System Spray Foam Machine E3

Product Description

Polyurethane Spray Machine is a professional, cost-effective polyurethane spray and injection machine. It is equipped with a specially designed horizontal booster pump, which not only has small fluctuations in working pressure, but also has less wearing parts and is easy to maintain.

Application:

construction, automobile, road, railway, shipbuilding, mining, petroleum, electrical, and other industries.

Product Overviews

| Technical parameters | Product advantages | |

| power | three-phase380V 50Hz | 1, The cylinder and solenoid valve are international brand "Yadeke" products, which are durable and powerful; 2, with small size, light weight, low failure rate, simple operation, easy to move and so on; 3, the most advanced international ventilation mode, to ensure the maximum degree of equipment work stability; 4, four-weight raw material filtration device can minimize the problem of spraying blockage; 5, multiple leakage protection system can protect the safety of operators; 6, equipped with emergency switch system, can be the most rapid response to emergency situations; 7, reliable and powerful 380V heating system can make raw materials quickly warm up to the ideal state, to meet the equipment in the cold area of normal construction; 8, equipment operating panel humanized settings, it is easy to master the mode of operation; 9, the latest new spray gun has the advantages of small size, light weight, simple operation, better atomization effect and so on; 10, the feeding pump using a large variable ratio mode, winter raw material viscosity is also easy to feed; |

| Heating power | 18KW | |

| Driven mode | pneumatic | |

| Air source | 0.5~0.8MPa≥1.2m3/minute | |

| Material output | 2~10kg/minute | |

| Max pressure | 30Mpa | |

| AB ratio | 1:01 | |

Packaging & Shipping

Hot Searches