- Product Details

- {{item.text}}

Quick Details

-

Power:

-

22/11KW

-

Weight:

-

2050

-

Dimension(L*W*H):

-

2850*1400*800mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Chemical Industry

-

Material:

-

Stainless Steel

-

Capacity:

-

5-15tons/h

-

Function:

-

Removing Impurities

-

Machine type:

-

Decanter Cantrifuge

-

Discharge:

-

Automatic Discharge

-

Operation:

-

Continuous

-

Item:

-

Continuous Decanter Centrifuge

-

Keyword:

-

Decanter Centrifuge

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

WANDA

-

Voltage:

-

380V/415V/220V

-

Power:

-

22/11KW

-

Weight:

-

2050

-

Dimension(L*W*H):

-

2850*1400*800mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Chemical Industry

-

Material:

-

Stainless Steel

-

Capacity:

-

5-15tons/h

-

Function:

-

Removing Impurities

-

Machine type:

-

Decanter Cantrifuge

-

Discharge:

-

Automatic Discharge

-

Operation:

-

Continuous

-

Item:

-

Continuous Decanter Centrifuge

-

Keyword:

-

Decanter Centrifuge

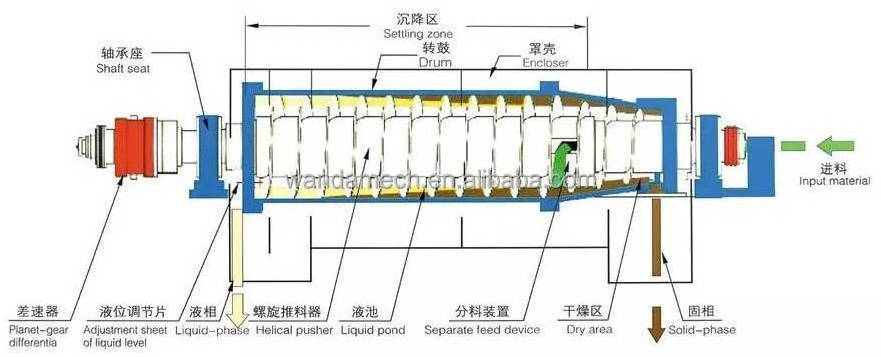

China Decanter Centrifuge Continuous Flow Horizontal Decanter Centrifuge for Sludge Dewatering

Product Description

Horizontal screw decanter centrifuge is a kind of spiral discharge settling centrifuge, it works continuously, which is pushes the slag to discharge port at the small end of the drum through the blades on the spiral pusher, and the liquid phase overflows through the overflow hole at the large end of the drum to achieve the purpose of continuous separation.

It has the advantages of:

1. Two motor, two frequency inverter drive system, realize differential speed stepless regulation and energy return.

2. Spiral stoker blades: Surfacing welding tungsten carbide grinding.

3. Drum cone cylinder material outlet: Replaceable wear resistant, corrosion resistant ceramic alloy bushing.

4. Main sealing parts: material is Nitrile butadiene rubber

5. Electrical protection: overload, phase loss, torque protection

6. Main and vice inverter use common DC bus, vice motor’s function is generating electricity ( save electricity)

7. PLC remote control.

2. Spiral stoker blades: Surfacing welding tungsten carbide grinding.

3. Drum cone cylinder material outlet: Replaceable wear resistant, corrosion resistant ceramic alloy bushing.

4. Main sealing parts: material is Nitrile butadiene rubber

5. Electrical protection: overload, phase loss, torque protection

6. Main and vice inverter use common DC bus, vice motor’s function is generating electricity ( save electricity)

7. PLC remote control.

Structure

This machine is horizontal spiral discharging settling centrifuge, the main machine has a column-cone bowl, spiral stoker,

differential system, bearing seat, base, cover, main motor,vice motor, and electric control chamber. With the high speed rotating of bowl, form strong centrifugal force, making the sludge dehydrate continuously in 24 hours a day.

The main motor through the triangle belt make the bowl rotating, through the planetary gear differential, make the vice motor and spiral differential speed different, realize sludge dewatering and pushing material function, That means differential rotating speed control and torque control. because containing solid rate of sludge may have wave motion, by differential speed control system is the guarantee for speed stability, achieve solid content in sludge is constant, the constant torque control make decanter load in a stable state, the separation effect and flocculation is the best state, so as to ensure the safe operation of the centrifuge.

differential system, bearing seat, base, cover, main motor,vice motor, and electric control chamber. With the high speed rotating of bowl, form strong centrifugal force, making the sludge dehydrate continuously in 24 hours a day.

The main motor through the triangle belt make the bowl rotating, through the planetary gear differential, make the vice motor and spiral differential speed different, realize sludge dewatering and pushing material function, That means differential rotating speed control and torque control. because containing solid rate of sludge may have wave motion, by differential speed control system is the guarantee for speed stability, achieve solid content in sludge is constant, the constant torque control make decanter load in a stable state, the separation effect and flocculation is the best state, so as to ensure the safe operation of the centrifuge.

This machine has good seal performance (guarantee without material leak in the process of operation), sludge dewatering work in full seal state, makes the environment clean.

This machine adopts the most advanced international special structural design, especially the spiral stoker, make the sludge concentration dehydration integration characteristics. It has better performance than ordinary centrifuge, more high capacity, better separation effect, save energy and manual work.

This machine adopts the most advanced international special structural design, especially the spiral stoker, make the sludge concentration dehydration integration characteristics. It has better performance than ordinary centrifuge, more high capacity, better separation effect, save energy and manual work.

Product Display

Two Phase Decanter Centrifuge

Three Phase Decanter Centrifuge

Product Parameters

Two Phase Decanter Centrifuge

Three Phase Decanter Centrifuge

Application Field

It is widely used in the production of chemical , printing, metallurgical coal mine, oil production, metallurgy ,iron and steel,

fabric ,food, drink, starch, dyes and so on, and it can also solve industrial and municipal wastewater. By use it, solid can be

dehydrated, liquid can be clarified.

fabric ,food, drink, starch, dyes and so on, and it can also solve industrial and municipal wastewater. By use it, solid can be

dehydrated, liquid can be clarified.

Product Packaging

Hot Searches