- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

LY,6-S shaking table

-

Voltage:

-

Customized

-

Power:

-

1.1kw

-

Dimension(L*W*H):

-

4500*1850*1560

-

Weight:

-

750kg

-

Warranty:

-

1 Year Excluding Wearing Parts

-

Certification:

-

CE; SGS; TUV;ISO9001:2008

-

Installation:

-

Technical guidance

-

Models available:

-

6-s,LS4500, LY3000, LY2100 and LY1100

-

Price:

-

Negotiable

-

Material:

-

Fiberglass ;Fberglass Reinforced Plastic

-

Application:

-

gold,silver,tin,tungsten,iron,chrome

-

Length:

-

4500

-

Dip:

-

Adjustable

-

Deck:

-

Three types

-

Other:

-

Detal as following

Quick Details

-

Production Capacity:

-

0.5-1.8t/h

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Gaoxuan

-

Model Number:

-

LY,6-S shaking table

-

Voltage:

-

Customized

-

Power:

-

1.1kw

-

Dimension(L*W*H):

-

4500*1850*1560

-

Weight:

-

750kg

-

Warranty:

-

1 Year Excluding Wearing Parts

-

Certification:

-

CE; SGS; TUV;ISO9001:2008

-

Installation:

-

Technical guidance

-

Models available:

-

6-s,LS4500, LY3000, LY2100 and LY1100

-

Price:

-

Negotiable

-

Material:

-

Fiberglass ;Fberglass Reinforced Plastic

-

Application:

-

gold,silver,tin,tungsten,iron,chrome

-

Length:

-

4500

-

Dip:

-

Adjustable

-

Deck:

-

Three types

-

Other:

-

Detal as following

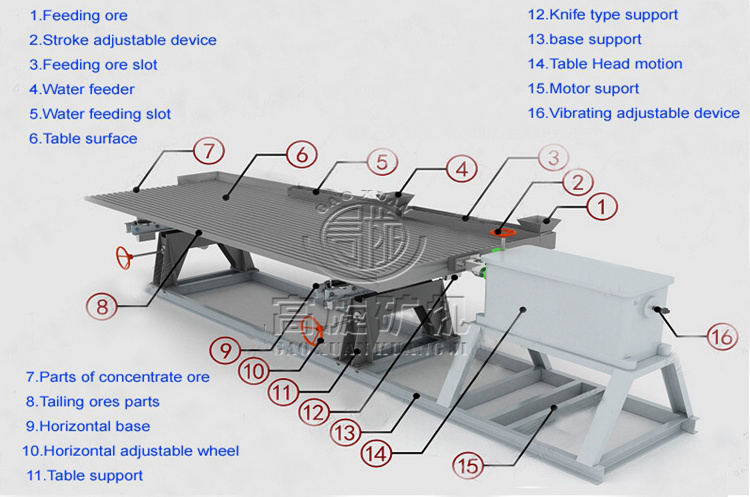

Gravity separating machine for use in the enrichment of gold shaking table gold mining machine

Gravity separating machine gold shaking table is one of most commonly used mineral beneficiation equipment,although the processing abilitybased on unit area of shaking table is low,but its effective particles size sorting could be up to 0.037mm limit,the interval grill of table surface is very clear and machine operating is easy.Shaking table could continuously sort concentrate ore,second grade ore and tailings,it is very important ore sorting equipment.Shaking table is made of machine head,motor,adjustingradient device,bed,bunker,water tank,rifle bar and lubrication system.

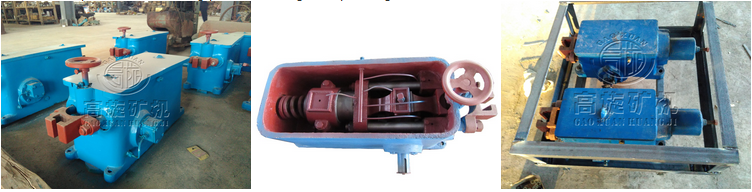

1. Head Motion

Gold shaking table cast iron to contain an oil reservoir for perfect splash lubricaion.

This feature protects the moving parts, reducing the operating and maintenance cost to minimum.

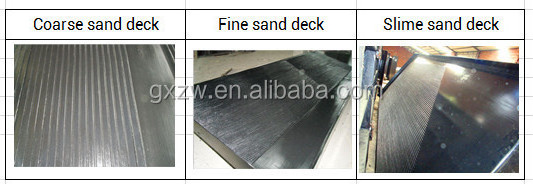

2. Decks

Shaking Table have three distinct deck designs available.

l Course ore deck is designed for recovering particles size from 0.5 mm to 2 mm;

l Fine sand deck is designed for recovering fine particles in the range of 0.074 mm to 0.5 mm;

l Slime deck is designed for recovering super extremely fine particles in the range of 0.05 mm to 0.074 mm.

3. Base Support

Installing foundation of shaking table have three styles.

| Ordinary foundation | 10# Small Channel Steel Support | 28# Big Channel Steel Support |

Gravity separating machine gold shaking table is one of the main equipment of gravity concentration. Shaking Table is not only widely applied on separating tungsten, the tin, the tantalum niobium and other rare metals and the noble metal ore. Also widely used in separation for Gold, Silver, Tin, Columbium, Tantalum, Titanium, Barium, Tungsten, Iron, Chrome,Manganese, Zircon, Lead, Zinc, Mercury, Copper, Aluminum, etc.

The shaker effective recycling granularity scope is 2-0.037 millimeters.

Packaging & Shipping

| Payment Terms of Shaker Table |

| • We usually accept T/T, L/C |

| • T/T: 30% of total amount as deposit, 70% balance before delivery. |

| • We will take pictures of finished products to you before delivery. |

| Way of Packing of Shaker Table |

| • FCL & LCL export standard container 20/40 feet. |

| • FCL: Sea-worthy package. Machines are fixed in container; spare parts are packed in wooden boxes. |

| • LCL: Machines are packed in steel frame with plywood boxes. Customized package is available. |

| Shipping of Shaker Table |

| • By sea shipment |

| MSK/MSC/APL/EMC/PIL and so on |

| • By air shipment |

| • By courier express |

| The lab equipment could be delivered by the courier express, such as UPS, DHL etc. |

We provide 12months quality warranty to make sure gravity jig machine well runs consistently.

Pre-sale services:

a. Professional engineer design the production line for you

b.Recommend suitable equipment according to your special demand.

During-sale services:

a.Pre-check and accept products before delivery

b.Send technicians to the jobsite for guiding the installation and adjustment

c.Training operators and finishing the check to satisfy your requiremnet

After-sale services:

a.Common problem can be solved through web in 24 hours,complex problem can be reacted immediately in 24 hours and solved as soon as possible

b.To establish long-term friendship, we will regulary contact with our customers.