Application:

1. Multi-purpose pet, fish, shrimp puffing feed machine.

2. This model can be used: suspended aquatic feed pellets, sink fish, shrimp and crab feed pellets, pet feed pellets, hanging

fishing feed pellets, etc.

3. Suitable for dogs, cats, fish, birds, rabbits, shrimps, dogs, cats, donkeys, foxes, etc.

4. Feed pellet machine, widely used in large, medium and small aquaculture, grain and feed processing plants, livestock farms,

poultry farms, individual breeding, Households, small, medium-sized farms, farmers or large, medium and small feed processing

plants, and etc.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380v

-

Dimension(L*W*H):

-

850*370*700mm

-

Weight:

-

45 kg

-

Marketing Type:

-

New Product 2024

-

Product name:

-

goat sheep feed pellet making machine for livestock farm

-

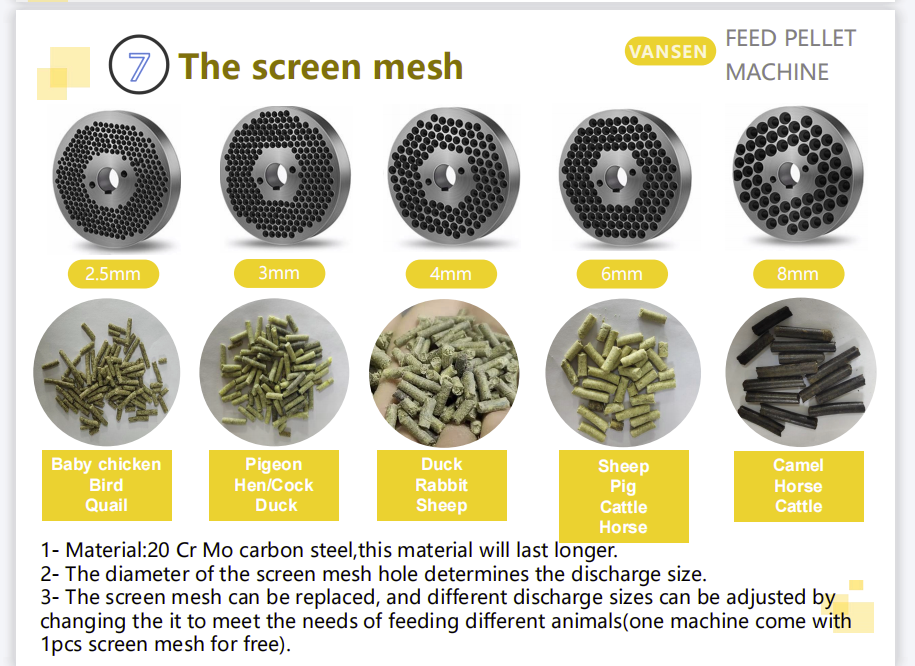

Die Plate Hole Diameter:

-

2.5-10 mm

-

Certification:

-

CE&ISO feed pellet processing machines

-

Keywords:

-

Feed Pellet Machine Mill

-

Color:

-

Customers' Requirement

-

Application:

-

Producing Animal Feeds Pellets

-

Motor:

-

Electric Diesel Gasoline Engine

-

Suit for:

-

Cow.sheep.pig Goose.duck.chicken.etc

-

Size:

-

Cutomized

Quick Details

-

Max. Capacity:

-

800 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Shengjia

-

Voltage:

-

220/380v

-

Dimension(L*W*H):

-

850*370*700mm

-

Weight:

-

45 kg

-

Marketing Type:

-

New Product 2024

-

Product name:

-

goat sheep feed pellet making machine for livestock farm

-

Die Plate Hole Diameter:

-

2.5-10 mm

-

Certification:

-

CE&ISO feed pellet processing machines

-

Keywords:

-

Feed Pellet Machine Mill

-

Color:

-

Customers' Requirement

-

Application:

-

Producing Animal Feeds Pellets

-

Motor:

-

Electric Diesel Gasoline Engine

-

Suit for:

-

Cow.sheep.pig Goose.duck.chicken.etc

-

Size:

-

Cutomized

7.5kw 200-300kg/h granulator pellet pig cattle goat sheep feed pellet making machine for livestock farm

Specification

|

Type

|

Power

|

Production capacity (kg/h)

|

Particle diameter (mm)

|

Particle length (mm)

|

|

SJ125

|

4KW

|

60-100

|

3-4.5

|

5-10

|

|

SJ150

|

4.5KW

|

100-200

|

3-4.5

|

5-10

|

|

SJ160

|

5.5KW

|

200-400

|

3-6

|

5-10

|

|

SJ210

|

7.5-11KW

|

500-600

|

3-6

|

5-15

|

|

SJ230

|

15KW

|

600-700

|

3-6

|

5-15

|

|

SJ260

|

18.5KW

|

700-800

|

3-6

|

5-15

|

|

SJ280

|

18.5KW

|

800-1000

|

3-9

|

5-20

|

|

SJ300

|

22KW

|

1000-1400

|

3-9

|

5-20

|

|

SJ400

|

30/37KW

|

1500-1600

|

3-12

|

5-25

|

|

SJ500

|

45/55KW

|

1700-2000

|

3-12

|

5-25

|

|

SJ600

|

75KW

|

2500+

|

3-12

|

5-25

|

Product Description

Animal Feed Machine Processing

2-8mm Farm Animal Feed Pellet Making Machine Mill Chicken Feed Pellet Duck Mill Machine Meat and bone meal, hay, straw, corn,

soybeans and other grains are suitable. The total humidity of raw materials should be controlled at about 5%-10%. It is used for producing pellet feed for farm animals, such as chickens, pigs and cows etc

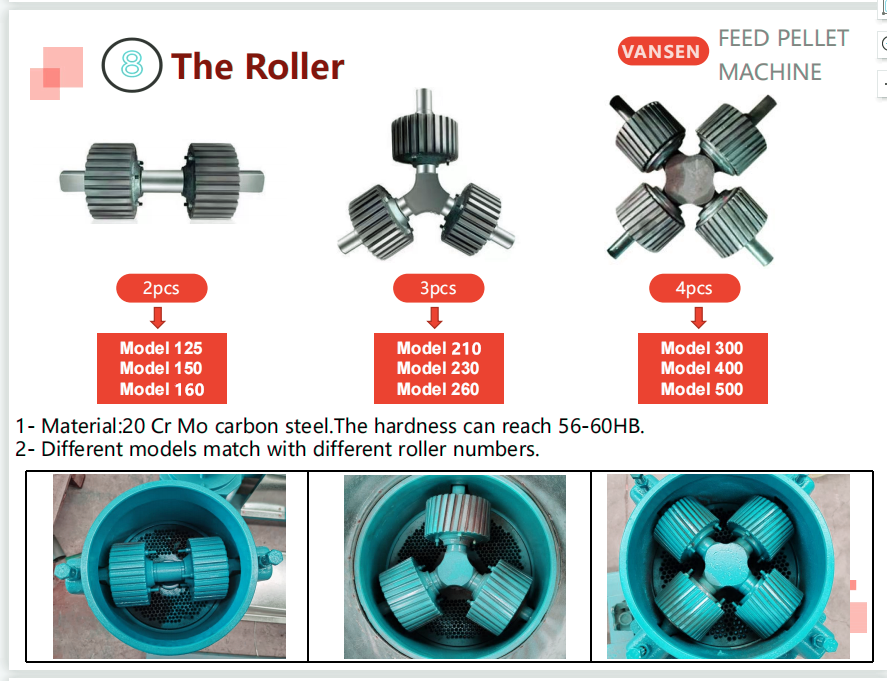

1. After keeping the balance of the nuts on both sides, the discharge speed can be adjusted by adjusting the distance between

the pressing roller and the grinding disc, and the adjustment range is 0.1-0.3mm

2. The pressure rollers and grinding discs are made of high-quality manganese steel after high temperature quenching treatment,

with high wear resistance. The surface of the fuselage is painted to resist corrosion

3. The enlarged feeding port design makes feeding more convenient and high working efficiency. The baffle design of the

discharge port can effectively prevent the feed from scattering. The machine is equipped with wheels for easy movement

Feature

1.Drive mechanism adopts high strength belt, with steady running and low noise;

2.Drive mechanism adopts high quality bearing to ensure high speed and stable operation;

3. Feeding part is equipped with a permanent magnet to remove metallic impurities; this prolongs the service life of main parts and meanwhile reduce the use of auxiliary equipment

Advantages:

1. Factory direct price, no middleman make the profits.

2. No reason to return for 7 days

3. Multi-purpose, It can be matched with more than a dozen pieces of farm tools(trailer, rotary tiller, trencher, seeder,harvester, etc.)

4. Best-selling products, cooperated with well-known companies

5. Equipped with with self-generating device, easy to start charging

6. Support OEM customization

Feed pellet machine is divided into ring die feed pellet machine, flat die feed pellet machine, and roller feed pellet machine;

according to the application, it can be divided into: small household pellet feed machine, poultry feed pellet machine, small

poultry pellet feed machine, fish feed pellet machine machine, rabbit feed pellet machine, pig feed pellet machine, straw feed

pellet machine; according to production, it can be divided into: straw feed pellet machine, wheat bran feed pellet machine,soybean meal feed pellet machine, corn straw feed pellet machine, wood chip feed pellet machine wait. Various feed pellet machines are classified according to their appearance and production methods.

Our Machine adopt word-famous brand for the key electronic elements, pneumatic and hydraulic system to ensure high quality andreliable of the Agriculture machinery and feed machinery After the unremitting efforts of all staffs , Hengfeng won the approval and trust of the customers with the excellent performance , advanced technology and good reputation. Our machines are widely used

in various fields of China and have exported to Southeast Asia, Europe, Africa, South America, Middle East Countries, and other areas. Europe technology, perfect performance. Hengfeng Machine is your reliable mechanical supplier. We have very attractive prices and looking for oversea agents ,welcome contact us for further information and you will be surprised of the significant savings that your company can achieve by working with us.

2-8mm Farm Animal Feed Pellet Making Machine Mill Chicken Feed Pellet Duck Mill Machine Meat and bone meal, hay, straw, corn,

soybeans and other grains are suitable. The total humidity of raw materials should be controlled at about 5%-10%. It is used for producing pellet feed for farm animals, such as chickens, pigs and cows etc

1. After keeping the balance of the nuts on both sides, the discharge speed can be adjusted by adjusting the distance between

the pressing roller and the grinding disc, and the adjustment range is 0.1-0.3mm

2. The pressure rollers and grinding discs are made of high-quality manganese steel after high temperature quenching treatment,

with high wear resistance. The surface of the fuselage is painted to resist corrosion

3. The enlarged feeding port design makes feeding more convenient and high working efficiency. The baffle design of the

discharge port can effectively prevent the feed from scattering. The machine is equipped with wheels for easy movement

Feature

1.Drive mechanism adopts high strength belt, with steady running and low noise;

2.Drive mechanism adopts high quality bearing to ensure high speed and stable operation;

3. Feeding part is equipped with a permanent magnet to remove metallic impurities; this prolongs the service life of main parts and meanwhile reduce the use of auxiliary equipment

Advantages:

1. Factory direct price, no middleman make the profits.

2. No reason to return for 7 days

3. Multi-purpose, It can be matched with more than a dozen pieces of farm tools(trailer, rotary tiller, trencher, seeder,harvester, etc.)

4. Best-selling products, cooperated with well-known companies

5. Equipped with with self-generating device, easy to start charging

6. Support OEM customization

Feed pellet machine is divided into ring die feed pellet machine, flat die feed pellet machine, and roller feed pellet machine;

according to the application, it can be divided into: small household pellet feed machine, poultry feed pellet machine, small

poultry pellet feed machine, fish feed pellet machine machine, rabbit feed pellet machine, pig feed pellet machine, straw feed

pellet machine; according to production, it can be divided into: straw feed pellet machine, wheat bran feed pellet machine,soybean meal feed pellet machine, corn straw feed pellet machine, wood chip feed pellet machine wait. Various feed pellet machines are classified according to their appearance and production methods.

Our Machine adopt word-famous brand for the key electronic elements, pneumatic and hydraulic system to ensure high quality andreliable of the Agriculture machinery and feed machinery After the unremitting efforts of all staffs , Hengfeng won the approval and trust of the customers with the excellent performance , advanced technology and good reputation. Our machines are widely used

in various fields of China and have exported to Southeast Asia, Europe, Africa, South America, Middle East Countries, and other areas. Europe technology, perfect performance. Hengfeng Machine is your reliable mechanical supplier. We have very attractive prices and looking for oversea agents ,welcome contact us for further information and you will be surprised of the significant savings that your company can achieve by working with us.

Product features: Pellet feed machine (output 50-2000 kg/h), based on the principle of circular motion, the template and pressure roller are made of high-strength, high-wear-resistant and high-heat-resistant alloy steel with special treatment, and the main shaft and flat die are under the action of friction drive the pressure roller to

rotate.

The material is slurried at high temperature between the pressing roller and the template, and the protein is coagulated and

denatured, and is discharged from the die hole under the pressing of the pressing roller. The particle length can be adjusted by

adjusting the incision, and the particle diameter can be adjusted by changing the abrasive tool.

There is no need to add water or drying during the granulation process. The starch can be gelatinized by natural heating up to

about 70 degrees Celsius, and various additives and drugs can be added without loss of nutrition and efficacy. The inside of the

granules is deeply matured (can kill 95% of pathogenic microorganisms and parasites), the surface is smooth, the hardness is

medium, and it can be stored for a long time. It is an ideal equipment and model for raising rabbits, fish, chickens, pigs, sheep,cattle and small and medium-sized feed processing plants to reduce breeding costs and improve economic benefits.

rotate.

The material is slurried at high temperature between the pressing roller and the template, and the protein is coagulated and

denatured, and is discharged from the die hole under the pressing of the pressing roller. The particle length can be adjusted by

adjusting the incision, and the particle diameter can be adjusted by changing the abrasive tool.

There is no need to add water or drying during the granulation process. The starch can be gelatinized by natural heating up to

about 70 degrees Celsius, and various additives and drugs can be added without loss of nutrition and efficacy. The inside of the

granules is deeply matured (can kill 95% of pathogenic microorganisms and parasites), the surface is smooth, the hardness is

medium, and it can be stored for a long time. It is an ideal equipment and model for raising rabbits, fish, chickens, pigs, sheep,cattle and small and medium-sized feed processing plants to reduce breeding costs and improve economic benefits.

The unit is mainly composed of material crushing, material mixing, material conveying, material extrusion, cooling and packaging

systems. The working process is to require the biomass pellet raw material with a moisture content of less than 15% to enter the

feeding auger from the hopper, adjust the number of revolutions of the electromagnetic speed-regulating motor to obtain a suitable

material flow, and then the granulator starts to granulate. .

systems. The working process is to require the biomass pellet raw material with a moisture content of less than 15% to enter the

feeding auger from the hopper, adjust the number of revolutions of the electromagnetic speed-regulating motor to obtain a suitable

material flow, and then the granulator starts to granulate. .

Packaging&Delivery

Similar products

grain milling grinding machine

Self-priming toothed disc crusher is a multi-functional mill, can be self-suction feeding.

It can crush a wide range of materials, sush as, chemical raw materials, herbs, gypsum powder, fish bone powder, calcium metal and

other materials, it also can be crushed corn, sorghum, dried potatoes, soybean cake and other miscellaneous grains and feed. This

product has the advantages of energy saving and environmental protection, high production efficiency, automatic feeding, fan and

unloading device. Greatly reduces the labor intensity of the operator!

It can crush a wide range of materials, sush as, chemical raw materials, herbs, gypsum powder, fish bone powder, calcium metal and

other materials, it also can be crushed corn, sorghum, dried potatoes, soybean cake and other miscellaneous grains and feed. This

product has the advantages of energy saving and environmental protection, high production efficiency, automatic feeding, fan and

unloading device. Greatly reduces the labor intensity of the operator!

hammer mill crusher

The purpose and characteristics of this series of crushers can crush various raw

materials, such as corn, sorghum, wheat, beans, corn straw, peanut seedlings, sweet potato seedlings, peanut skin, dry weeds, and other types of miscellaneous grains and dry feed And the roughly crushed cakes. The machine has a reasonable structure, is sturdy and durable, safe and reliable, easy to install, easy to operate, low vibration, and is suitable for individual or matching use in various feed factories.

materials, such as corn, sorghum, wheat, beans, corn straw, peanut seedlings, sweet potato seedlings, peanut skin, dry weeds, and other types of miscellaneous grains and dry feed And the roughly crushed cakes. The machine has a reasonable structure, is sturdy and durable, safe and reliable, easy to install, easy to operate, low vibration, and is suitable for individual or matching use in various feed factories.

Hot Searches