- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

2200 KG, 1000KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Customer's Demands

-

Power(W):

-

15kw

-

Certification:

-

ISO9001 CE

-

Glue type:

-

Butyl rubber

-

Feature:

-

High Efficency

-

Model:

-

XJ45/65/80/90/120/150

-

Heating type:

-

Electrical Heating

-

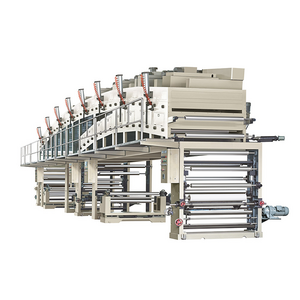

Machine Type:

-

Butyl rubber extruding equipment

Quick Details

-

Voltage:

-

380

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Shuangda

-

Weight:

-

2200 KG, 1000KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Customer's Demands

-

Power(W):

-

15kw

-

Certification:

-

ISO9001 CE

-

Glue type:

-

Butyl rubber

-

Feature:

-

High Efficency

-

Model:

-

XJ45/65/80/90/120/150

-

Heating type:

-

Electrical Heating

-

Machine Type:

-

Butyl rubber extruding equipment

|

Model |

XJ-50 |

XJ-65 |

XJ--90 |

XJ-120 |

|

Screw Diameter mm |

50 |

65 |

90 |

120 |

|

Motor Power kw |

15kw |

18kw |

22kw |

37kw |

|

Screw Speed r/min |

40 |

40 |

30 |

30 |

|

Output kg/h |

20-40 |

30-50 |

40-100 |

120-200 |

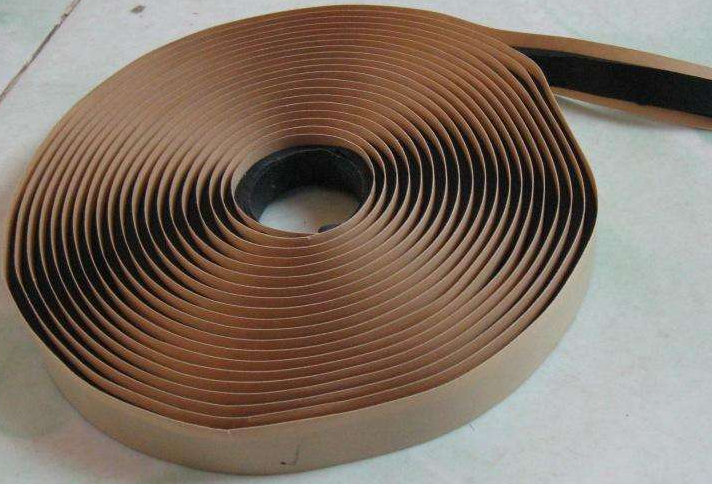

Butyl rubber extruder use to produce adhesive tape s , sealing tape s , sound insulation material s , damping material s , automobile door , window and chassis butyl rubber adhesive tape s , hollow glass butyl adhesive tape s , non - woven fabric butyl adhesive tape s , release paper butyl adhesive tape s , aluminum foil butyl adhesive tape s , waterproof coiled material s , and chewing gum base material (food) ,etc .

How to get the quick and exact quotation?

Please tell me the following information :

1. The size (length, width, thickness of one side or two sides) .

2. The material

3. The style of the pipe, hose, bar , sheet, or the profiles

4. The quantity

5. If possible please provide the picture or the sample of the products.

Can you design for us?

Of course.We have a professional team having rich experience in plastic extruder design and manufacturing.

Please tell us your resquest such as the output and the voltage . Then we will help to carry out your idesa into perfect Plastic or Rubber extrusion machine .

Are you factory or trading company?

Definitly a factory .We have 19 years experience of produc ing Extrusion machine. We hav e our ow n factory , production line and workers .We have been certified by ISO9001.

How do you guarantee the quality of your company?

Quality assurance: committed to providing products and services that meet customer needs and requirements; Through continuous improvement of products, processes, service quality, improve customer satisfaction. "honesty and trustworthiness, quality first, customer first" purpose, continuous development and innovation, dedicated to serving our customers!

Quality system: Shuangda machinery has been certified by ISO9001 quality management system. It has a perfect after-sales service team and has done a lot of basic work for the development of future projects.

How to use extruder correctly and reasonably?

The production capacity of each machine should be matched so that the equipment of the production line can work harmoniously.

The size of the extruder should be selected according to the specification of the product.

Should be equipped with a skilled technical operator. Have a skilled operation skills and know how to maintain the equipment.

The extruder should be safe, reliable and grounded, and the equipment should be moisture-proof and corrosion resistant.

Question of warranty period

We are very confident in our products, and we pack them very well , so usually you will receive your order in good condition.

But due to long time shipment there will be very few damage for the extrusion equipment.Any quality issue, we will deal with it immediately.

Order Guide:

1. Ship date: 30----120 working days

2. Payment terms: T/T or L/C

3. Full range of devices to be provided on schedule, as per client demands.

4. Responsible for training technicians and operators for operation and maintenance of the equipment.

5. Responsible for installing and debugging all devices.

6. Formula available and long term technical supports.

7. Guarantee: One year guaranteed repair and lifelong tracking service,with parts provided.

8. All the parameters of the machine on metric units and in English.

9. Package: standard export wooden pallet.