- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Keyword:

-

Punching Machine

-

Power Source:

-

Hydraulic Power Unit

-

CNC axes:

-

3

-

Dimension of letter (mm):

-

14*10*19

-

Punches per side:

-

3

-

Group of Marking letters:

-

4

Quick Details

-

Application:

-

Angle Tower

-

Function:

-

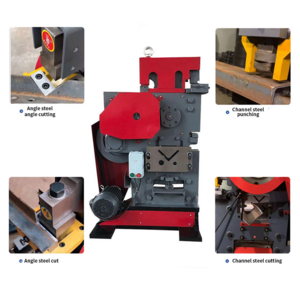

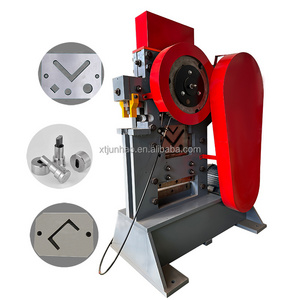

Steel Punching, Marking and Shearing

-

Certification:

-

CE, ISO9001

-

Voltage:

-

380V

-

Keyword:

-

Punching Machine

-

Power Source:

-

Hydraulic Power Unit

-

CNC axes:

-

3

-

Dimension of letter (mm):

-

14*10*19

-

Punches per side:

-

3

-

Group of Marking letters:

-

4

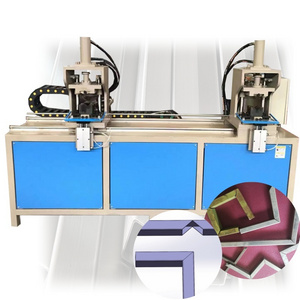

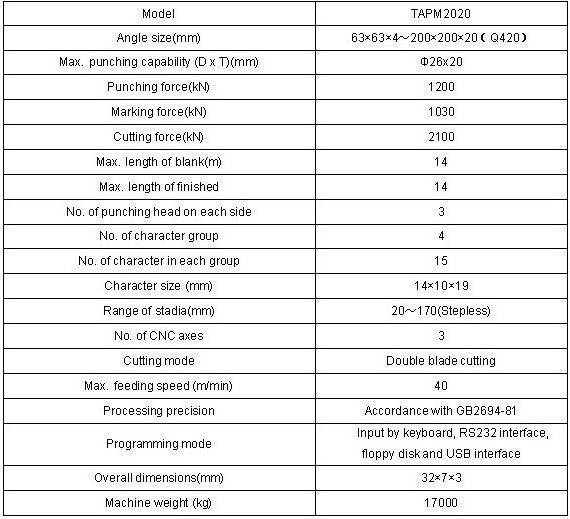

CNC Angle Iron Punching Cutting Machine

Applicable Industry:

This machine is the automatic special production line used for angle steel marking, punching, and shearing mainly in the field of angle steel tower industry, electric power fittings, structure storage facilities, and steel structure construction industries etc.

Product Feature:

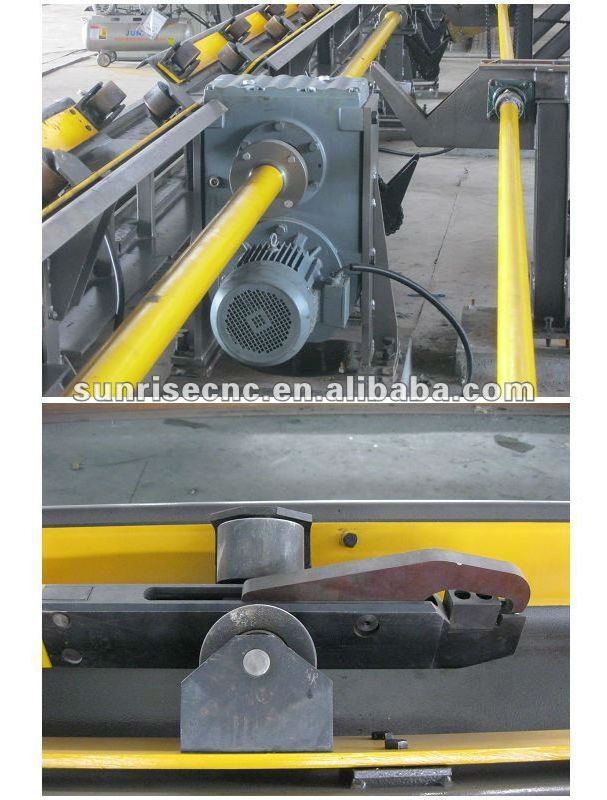

1. Advanced angle supporting device, has obtained the national patent certificate, which improve the angle processing accuracy.

2. Three sets of punches on each side, can process all holes once time.

3. TBL2020, TAPM2020 Double blade shearing ,for high tensile large angles. TAPM2020A, TAPM2020C Single blade shearing, save raw material.

4. Numerical control processing, the operation is very convenient, can realize automation, high precision, many varieties, mass production.

5. Marking unit adopts closed frame with good rigidity . On the marking unit is equipped with four groups of programmable selection box.

6. With avoided shearing functions, so as to process fixed-length angles.

7. All marking, punching and Cutting in automatic completeness, all finished angles can be unloaded by pneumatic turnover device so as to lighten the working strength.

8. Easy programming, adopt instruction programming and lofting software . It can read .NC1 files generated by TEKLA software.

SPECIFICATIONS:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

FAQ:

Q1. Are you a Manufacturer or a trading company?

A1.We are the manufacture, integrating with design, machining and assembling for angle machine.

Q2. Do you have stock product ready to deliver?

A2. In order to satisfy with the customer for fast delivery, we have certain amount of machines in stock, you can check the machine on LIVE-DEMONSTRATION at any time.

Q3. How do you deliver the finished products?

A3. The machine is mostly delivery by sea, rail way or road for some exception. For some urgent part or shipping document we delivered by air or Express like TNT, FEDEX,DHL,UPS,EMS, Etc.

Q4. How can you guarantee the after-sales service?

A4. We have the special after-sales service department, they will provide training program for operation and trouble shouting during installation. And they will visit the customer regularly for service. All questions will be answered within 3 hours and 90% problem will be solved within 24 hours.

Q5. What's delivery time for the angle machine.

A5. Within 20 days after payment.

Q6. How can you guarantee your finished angle machine quality?

A6. First, the machine will have 8 hours idle running; Second, we will test the machine with the material working together.