- Product Details

- {{item.text}}

Quick Details

-

Knitting Method:

-

Double

-

Computerized:

-

Yes

-

Gauge:

-

1.5 GG, 3 GG, 7 GG, 12 GG, 14 GG, 16 GG, 9 GG, 5 GG, 10GG, 2.5GG, 18GG, 16GG, 8GG, 3-5-7 multi-gauge, Other

-

Knitting width:

-

52 inch

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

YINENG

-

Power:

-

1200 W

-

Weight:

-

120 KG

-

Dimension(L*W*H):

-

2450X750X1750

-

Power supply::

-

AC220V 50Hz, 100W

-

Machinery Test Report::

-

Provided

-

Knitting width::

-

42 inch, 36, 40, 42

Quick Details

-

Type:

-

jacquard

-

Production Capacity:

-

100%

-

Knitting Style:

-

Warp

-

Knitting Method:

-

Double

-

Computerized:

-

Yes

-

Gauge:

-

1.5 GG, 3 GG, 7 GG, 12 GG, 14 GG, 16 GG, 9 GG, 5 GG, 10GG, 2.5GG, 18GG, 16GG, 8GG, 3-5-7 multi-gauge, Other

-

Knitting width:

-

52 inch

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

YINENG

-

Power:

-

1200 W

-

Weight:

-

120 KG

-

Dimension(L*W*H):

-

2450X750X1750

-

Power supply::

-

AC220V 50Hz, 100W

-

Machinery Test Report::

-

Provided

-

Knitting width::

-

42 inch, 36, 40, 42

Products Description

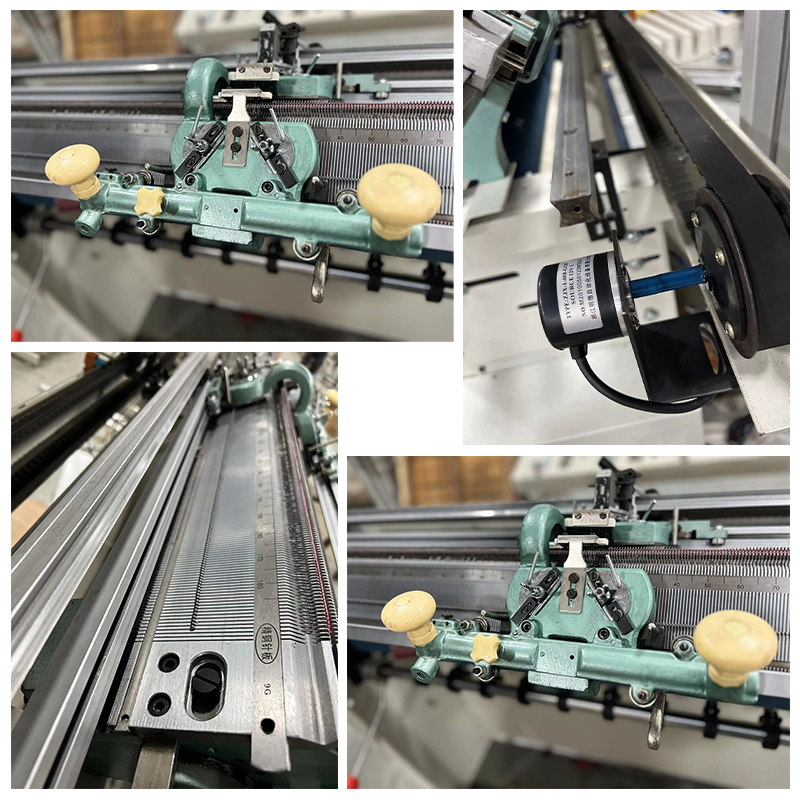

Customized laboratory semi-automatic computerized flat knitting machine with programmable controller in factory

YINENG Brand Have Single system/Double system/Three System.Guage types including1.5G\2G\3G\3.5G\5G\57G\7G\8G\10G\12G\14G\16G.

Suitable for wool, cashmere, cotton, chemical fiber, silk, as well as all kinds of blended yarn. It can be used for knitting:

sweaters, hats, scarves, shoe uppers, medical products, blankets, handicrafts, car cushions, summer mats, etc.

Suitable for wool, cashmere, cotton, chemical fiber, silk, as well as all kinds of blended yarn. It can be used for knitting:

sweaters, hats, scarves, shoe uppers, medical products, blankets, handicrafts, car cushions, summer mats, etc.

|

Model

|

MZ142S

|

|

Knitting width

|

36″, 40″, 42″

|

|

Needle gauge

|

2G, 3G, 5G, 7G, 9G, 10G, 12G, 14G, 16G

|

|

Needle type

|

Latch Needle

|

|

Knitting system

|

1

|

|

Number of feeders

|

2

|

|

Power supply

|

AC220V 50Hz, 100W

|

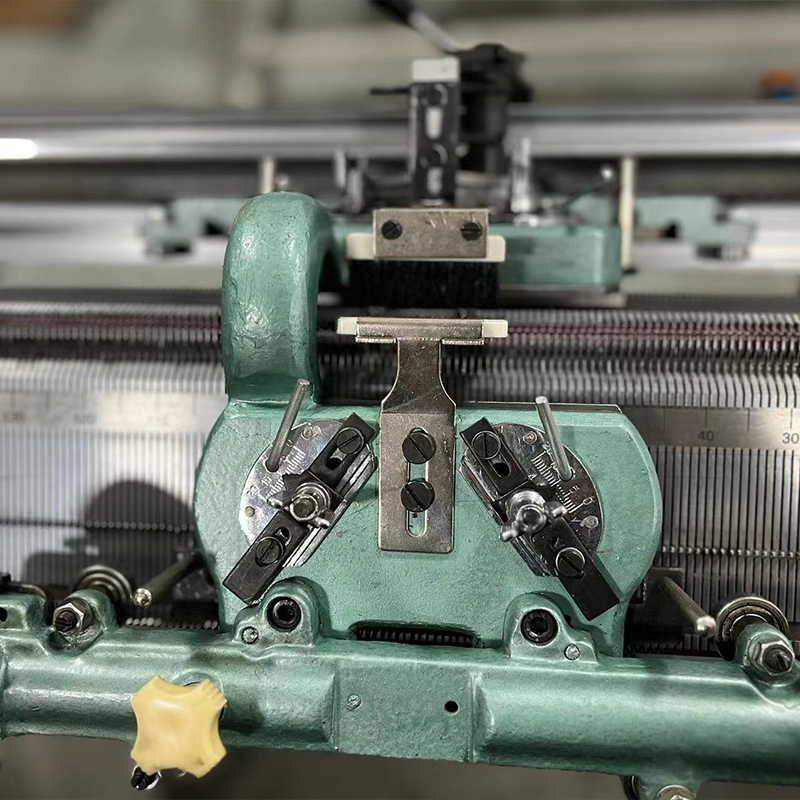

Yarn Feeder

We used the Intarsia yarn feeder combination, Two yarn feeding pulleys are placed in each set of yarn feeders to ensure that the yarn enters smoothly without breaking

we use yarn feeders of different structures for the shoe upper machine and the sweater machine.

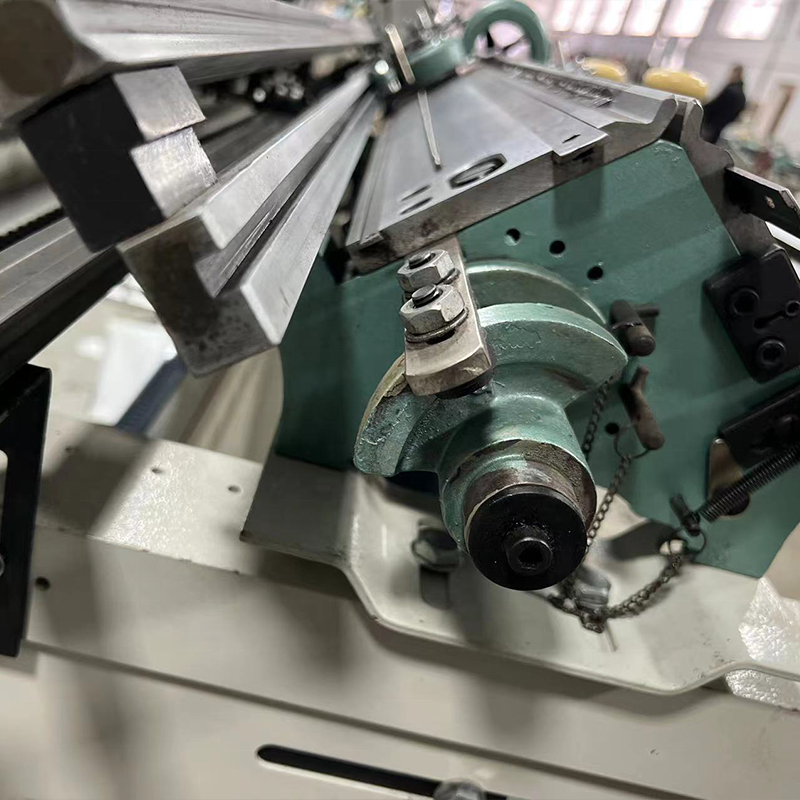

Automatic refueling

Automatic refueling device, with automatic reminders for insufficient oil volume and insufficient oil pressure, and the refueling time and interval time can be used to achieve timing and quantitative feeding to high-speed machines.

Automatic refueling wave-slip to prevent the problem of oil needle or grinding connection caused by too much or too little refueling caused by human factors, and increase the service life of the machine.

TOP Sensor

The upper tension device adopts an operation mode that can quickly and easily thread the yarn. During the knitting process, when a big knot is detected, the machine will stop; when a small knot is detected, the machine head will slow down, thereby enhancing quality management.

Needle plate

The needle plate is made of SK5 high-strength material, which is run-in with the needle Some inserts are fine-blanked and ground Made, less breakage and pin wear reduce pins resistance, improving the efficiency of machine weaving.

Machine Detail

Certifications

Mingzhou Factory

Packing And Deliver

FAQ

1. Who are we?

We are a real factory, headquartered in China knitting machinery industry base, Zhangjiagang, Jiangsu. The company was founded in 2011, our production team has more than 15 years of production experience.

2. How to choose the most suitable mechanical equipment?

Our professional team will give you the best advice, as long as you tell us what kind of tests need to be done and the required specifications.

3. What can you buy from us?

Collar knitting machine, sweater knitting machine, mat knitting machine, uppers knitting machine, sweater dial connecting machine, yarn winding machine

4. Do you accept custom service?

Of course, we can not only provide the standard machines, but also customize the machines according to your requirements. Don't hesitate to tell us your needs and we will do our best to meet them.

5. How do I replace a spare part?

Generally speaking, our warranty period is eighteen months. For each machine, we will provide 2% of spare parts free of charge. If some parts are broken, you can replace them yourself, during the warranty period, we can provide technical support and parts replacement, when necessary, our engineers can come to your place for better service.

6. Machine packaging

The inner layer is plastic packaging to avoid dust; The middle layer is vacuum packed to avoid moisture and rust at sea

Transport; The outside is fixed in wooden cases to protect the machine during transportation

Hot Searches