- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Customized

-

Dimension(L*W*H):

-

1500*1220*1650 or Customized

-

Weight:

-

14580

-

Name:

-

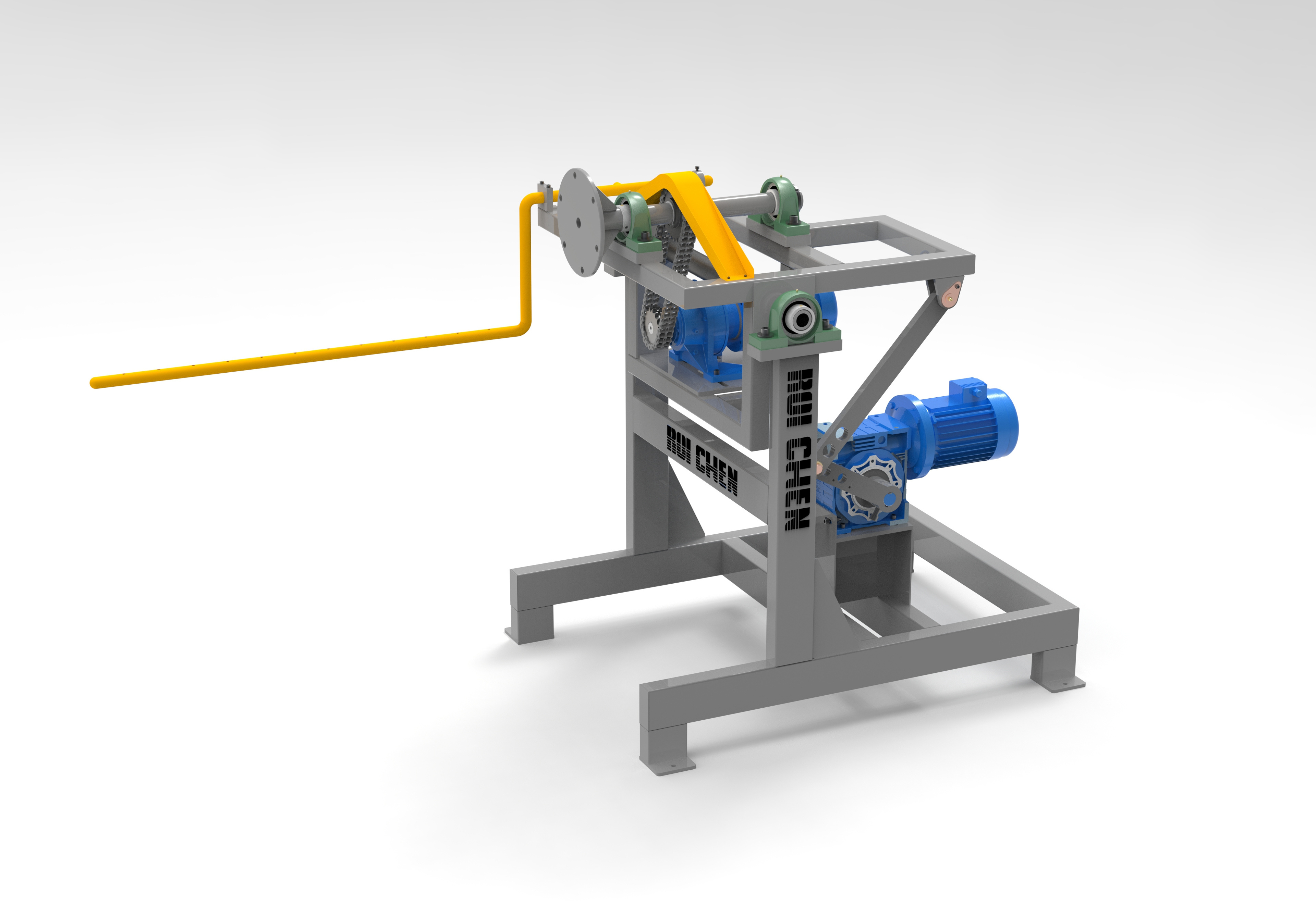

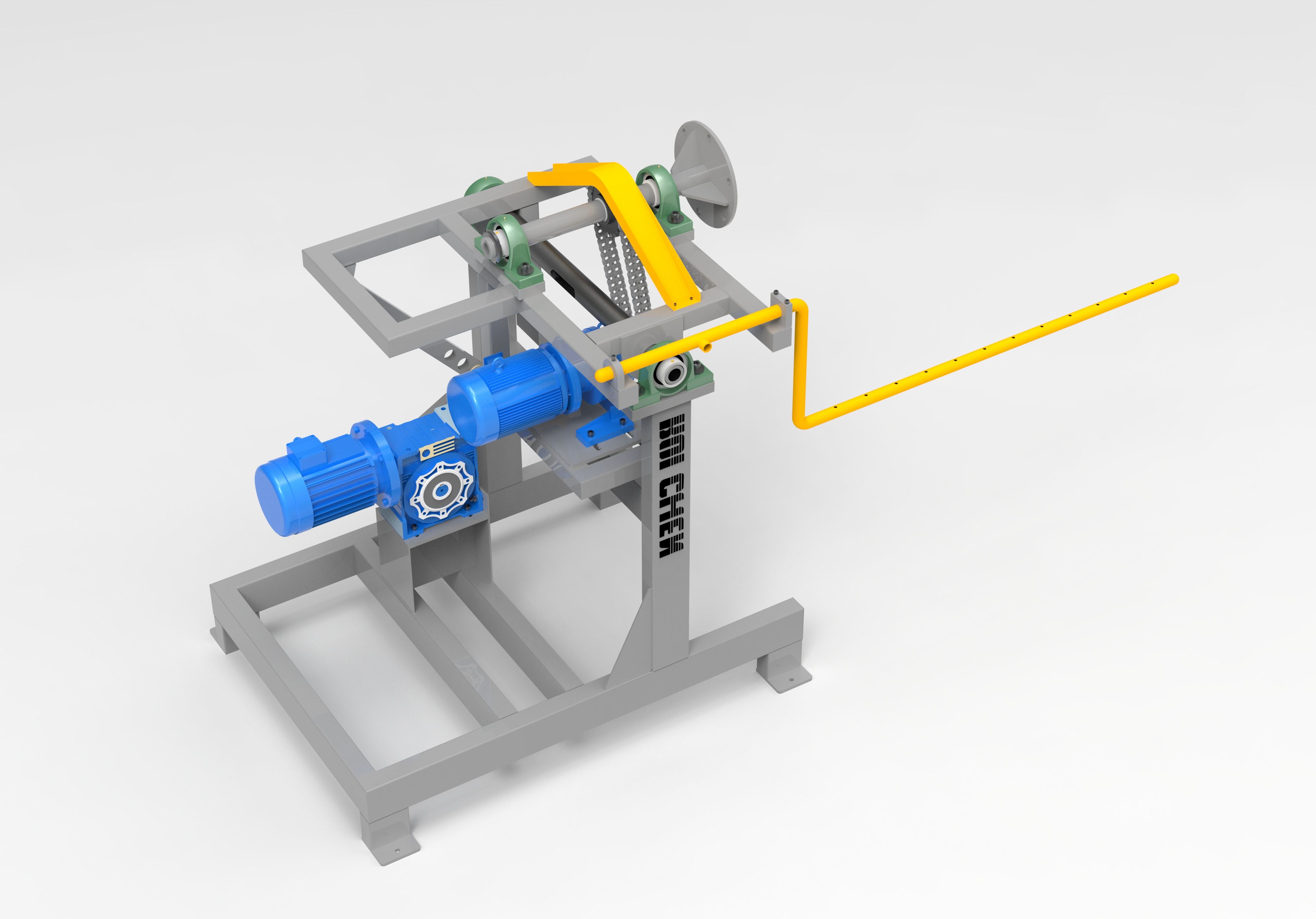

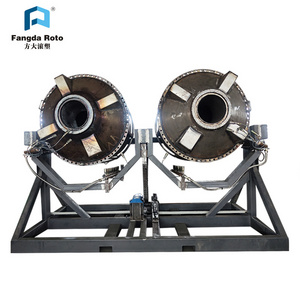

Polyethylene Rock And Roll Rotational Moulding Machine

-

Transmission power:

-

1.1kw

-

Noise:

-

Low noise

-

Type:

-

Fully automatic

-

Color:

-

Blue and white or customized

-

Transportation mode:

-

By sea

-

Application:

-

Plastic Products

-

MOQ:

-

1 Set

-

Hydraulic system power:

-

2.2kw

-

Delivery time:

-

Wthin 60 Days

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Ruichen

-

Voltage:

-

Customized

-

Power:

-

Customized

-

Dimension(L*W*H):

-

1500*1220*1650 or Customized

-

Weight:

-

14580

-

Name:

-

Polyethylene Rock And Roll Rotational Moulding Machine

-

Transmission power:

-

1.1kw

-

Noise:

-

Low noise

-

Type:

-

Fully automatic

-

Color:

-

Blue and white or customized

-

Transportation mode:

-

By sea

-

Application:

-

Plastic Products

-

MOQ:

-

1 Set

-

Hydraulic system power:

-

2.2kw

-

Delivery time:

-

Wthin 60 Days

|

Product name

|

2024 hot selling polyethylene rock and roll rotomoulding machine

|

|

Features

|

Characteristics of Open-flame Swing Plastic Molding Machine

Open flame rocking forming machinery and equipment is low cost, small area, suitable for large and medium-sized hollow products, easy to operate, easy to maintain, is the ideal equipment for the introduction of rolling molding. |

|

Basic process

|

1.a given quantity of plastic material,powder or liquid,islaid in one half of the mould

2.the mould is closed 3.the mould is rotated in the oven revolving on two axes. 4.plastic material melts,forming a coating layer on the mould internal surface. 5.the mould is removed from the oven and cooled off. 6.the mould is opened and the hollow item is extracted |

|

Producable products

|

1.Military industry

2.Car class 3.Cleaning class 4.Lining 5.Traffic facilities 6.Container class 7.Common environment class 8.Toy pet 9.Water supplies |

|

Process advantage

|

1.Low cost

2.Rotomolding machinery invests less than other plastic molding machines such as injection molding machines 3.Suitable for simultaneous production of multiple types of products 4.The surface of the product is straight and uniform in thickness 5.Suitable for large hollow products 6.products are not subject to high stress,little scraps are generated |

|

Model No

|

Processing interval: min/max

|

Installed capacity

|

control mode

|

Outline size

(A*B*H) |

|

|

|

|

|

transmission power Hydraulic system feed

|

turn

swing

|

1500*1220*1650

|

|

|

|

RC-YB-1200 1T

|

φ660*740/φ1100*1200(1300)

|

1.1kw

2.2kw

|

frequency conversion throttle valve

|

|

|

|

FAQ:

Q:Are you a manufacturer or a trading company?

A:We are a professional manufacturer of rotational molding machines.We have been in rotomolding industry for more than a decade.

Q:What is the transaction process?

A:The deposit is received to start production,and the final payment is received to be packed and shipped.Of course,we can negotiate the details!

Q:What is after-sales service?

A:The equipment has a 1-year warranty and lifetime maintenance;engineers perform on-site installion, video technology,training and production.

Q:Is the equipment inspected before delivery?

A:Yes,our professionals will perform a series of inspections on the equipment before leaving the factory to ensure that there is no problem with quality.

Q:Where is the company?

A:The company is located in Maanshan,Anhui,with convenient transportation.30 km away from Nanjing International Airport.Welcome buyers from all over the world to come the factory to negotiate!

A:We are a professional manufacturer of rotational molding machines.We have been in rotomolding industry for more than a decade.

Q:What is the transaction process?

A:The deposit is received to start production,and the final payment is received to be packed and shipped.Of course,we can negotiate the details!

Q:What is after-sales service?

A:The equipment has a 1-year warranty and lifetime maintenance;engineers perform on-site installion, video technology,training and production.

Q:Is the equipment inspected before delivery?

A:Yes,our professionals will perform a series of inspections on the equipment before leaving the factory to ensure that there is no problem with quality.

Q:Where is the company?

A:The company is located in Maanshan,Anhui,with convenient transportation.30 km away from Nanjing International Airport.Welcome buyers from all over the world to come the factory to negotiate!

Hot Searches