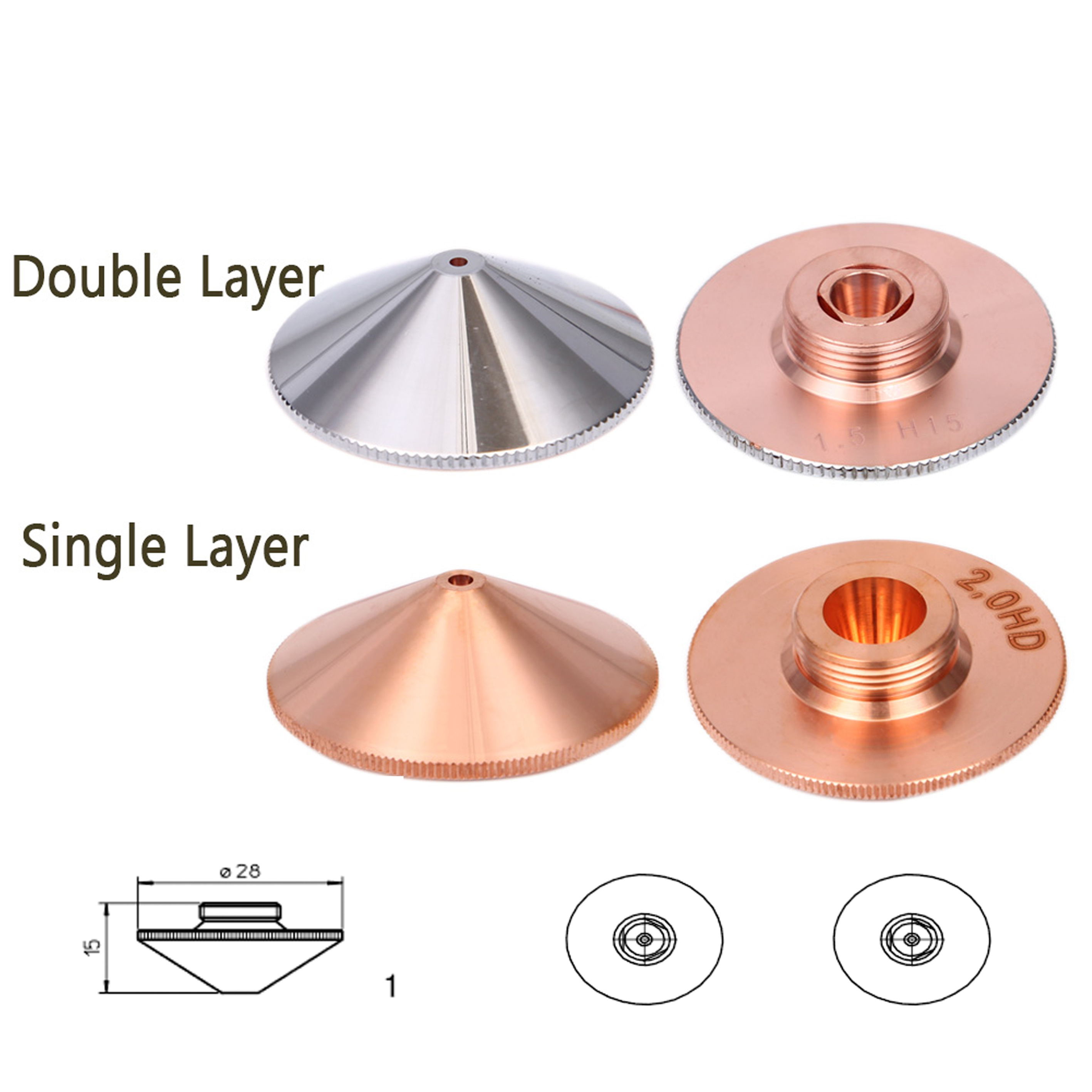

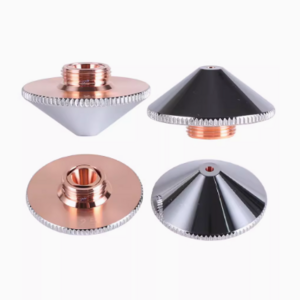

The nozzle caliber is often used in φ1.5mm and φ2mm.

1. For thin plate below 3mm,using φ1.5mm,

the cutting surface will be thinner;using φ2mm, the cutting surface will be thicker,

and the corners will be easily melted.

2.Thick plates above 3mm,φ2mm is better choice :

Due to the high cutting power, heat dissipation time is longer, and cutting time also increases. With φ1.5mm, the gas has a small diffusion area, so it is not stable when used but it is basically usable. With φ2mm, the gas diffusion area is large and the gas flow rate is slow, so it is stable when cutting.

the cutting surface will be thinner;using φ2mm, the cutting surface will be thicker,

and the corners will be easily melted.

2.Thick plates above 3mm,φ2mm is better choice :

Due to the high cutting power, heat dissipation time is longer, and cutting time also increases. With φ1.5mm, the gas has a small diffusion area, so it is not stable when used but it is basically usable. With φ2mm, the gas diffusion area is large and the gas flow rate is slow, so it is stable when cutting.