- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

csty

-

Material:

-

Gr2 Gr1 GR10

-

Outer Diameter:

-

OD50.8mm/51/55/57/60/63/63.5/65/66/70/80/76.2/89mm

-

Length:

-

500-12000mm

-

Application:

-

Heat Exchanger

-

Grade:

-

Gr1 Gr2 GR10

-

Wall Thickness:

-

0.3-2.0mm

-

Inside Diameter:

-

4~88mm

Quick Details

-

Standard:

-

ASME SB338

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

csty

-

Model Number:

-

csty

-

Material:

-

Gr2 Gr1 GR10

-

Outer Diameter:

-

OD50.8mm/51/55/57/60/63/63.5/65/66/70/80/76.2/89mm

-

Length:

-

500-12000mm

-

Application:

-

Heat Exchanger

-

Grade:

-

Gr1 Gr2 GR10

-

Wall Thickness:

-

0.3-2.0mm

-

Inside Diameter:

-

4~88mm

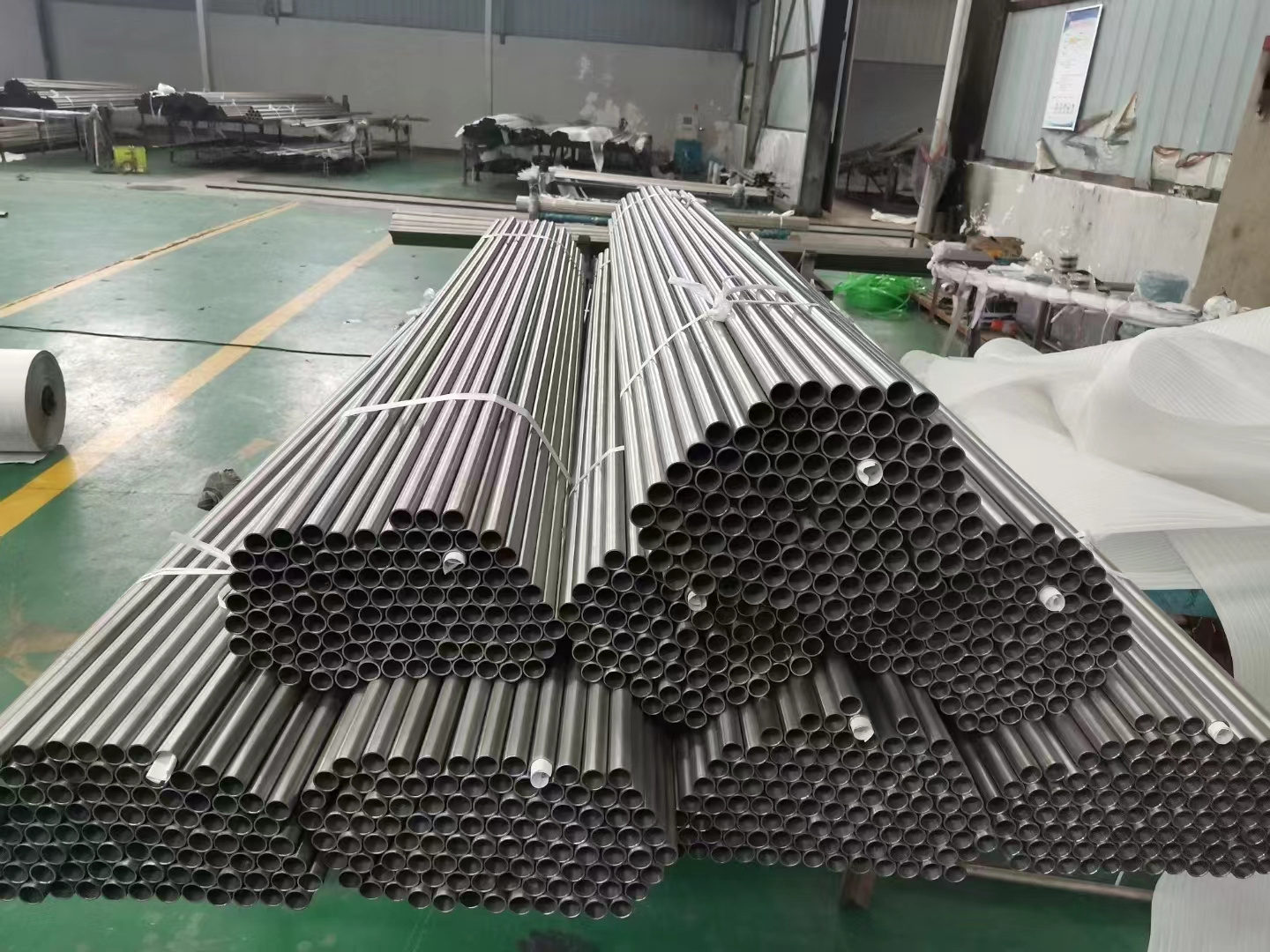

Specification

|

Name

|

Titanium tube/pipe

|

|

Standard

|

ASTM B338/ASME SB338, ASTM B337/ASME SB337, ASTM B861/ASME SB861, ASTM B862/ASME SB862,AMS4911,AMS4928

|

|

Grade

|

Gr1, Gr2, Gr4, Gr7, Gr9, Gr11, Gr12, etc

|

|

Size

|

Length: 50-6000mm or according to customer requirements

|

|

|

Outer diameter: 3-300mm or according to customer requirements

|

|

|

Wall thickness: 0.2-5.5mm or according to customer requirements

|

|

Section shape

|

Round / Square

|

|

Tolerance

|

a) Outer Diameter: +/- 0.01mm

b) Thickness: +/- 0.01mm c) Length: +/- 0.1mm |

|

Application

|

Industrial

|

|

Surface

|

Pickling, annealing, polishing

|

|

Feature

|

1.Low Density and High Strength

2.Excellent Corrosion Resistance 3.Good resistance to effect of heat 4.Excellent Bearing to cryogenic property 5.Nonmagnetic and Non-toxic 6.Good thermal properties 7.Low Modulus of Elasticity |

Product Description

Seamless tube and welded tube

The titanium seamless tube shall be made from hollow billet by any cold drawing or cold

reducing process with a continuous periphery in all stages of manufacturing operation. The titanium welded tube shall be made from

annealed, flat-rolled plates by an automatic arc-welding or other welding process.

Titanium welded tubes and pipes can be used in heat exchangers and condensers, all kinds of corrosive fluid transmission pipeline system, Titanium bicycle tube, automobile exhaust pipe and offshore aquaculture, etc..

reducing process with a continuous periphery in all stages of manufacturing operation. The titanium welded tube shall be made from

annealed, flat-rolled plates by an automatic arc-welding or other welding process.

Titanium welded tubes and pipes can be used in heat exchangers and condensers, all kinds of corrosive fluid transmission pipeline system, Titanium bicycle tube, automobile exhaust pipe and offshore aquaculture, etc..

Common Grades

Titanium Grade 1

is an unalloyed, low strength titanium product containing low oxygen with high formability; this titanium grade is used in airframes, heat exchangers and desalination units.

Titanium Grade 2 is an unalloyed, medium strength titanium product. This titanium grade is used in airframes, aircraft engines and marine parts; good weldability and corrosion resistance are its distinguishing characteristics.

Titanium Grade 3 is an unalloyed, high strength, titanium product providing excellent corrosion resistance and good weldability. This titanium grade is primarily used in airframe and aircraft engine parts.

Titanium Grade 4 is the highest strength pure unalloyed titanium product. This titanium grade is used almost exclusively for

airframe, aircraft engine parts, marine, surgical implants, hydraulic tubing. Good formability and corrosion resistance are its

hallmark.

Titanium Grade 5 (6AL-4V) is an alloyed titanium product containing 6% Aluminum and 4% Vanadium; is a medium strength product. This titanium grade is predominantly used in airframe and turbine engine parts; and for use in surgical implants. Technical Info Titanium 6AL – 4V ELI is an alloyed titanium product containing 6% Aluminum and 4% Vanadium, ELI (Extra Low Interstitial).

6AL–2Sn–4Zr–2Mo (6-2-4-2) is an alloyed titanium product containing 6% Aluminum, 2% Tin, 4% Zirconium, 2% Molybdenum.

6AL–6V–2Sn (6-6-2) is an alloyed titanium product containing 6% Aluminum, 6% Vanadium, 2% Tin.

5AL–2.5Sn & ELI (5-2.5) is an alloyed titanium product containing 5% Aluminum and 2.5% Tin. Also ELI (Extra Low Interstitial).

8AL–1V–1Mo (8-1-1) is an alloyed titanium product containing 8% Aluminum, 1% Molybdenum and 1% Vanadium.

15V–3Cr–4AL–3Sn (15-3-3-3) is an alloyed titanium product containing 15% Vanadium, 3% Chromium, 4% Aluminum, 3% Tin.

Titanium Grade 2 is an unalloyed, medium strength titanium product. This titanium grade is used in airframes, aircraft engines and marine parts; good weldability and corrosion resistance are its distinguishing characteristics.

Titanium Grade 3 is an unalloyed, high strength, titanium product providing excellent corrosion resistance and good weldability. This titanium grade is primarily used in airframe and aircraft engine parts.

Titanium Grade 4 is the highest strength pure unalloyed titanium product. This titanium grade is used almost exclusively for

airframe, aircraft engine parts, marine, surgical implants, hydraulic tubing. Good formability and corrosion resistance are its

hallmark.

Titanium Grade 5 (6AL-4V) is an alloyed titanium product containing 6% Aluminum and 4% Vanadium; is a medium strength product. This titanium grade is predominantly used in airframe and turbine engine parts; and for use in surgical implants. Technical Info Titanium 6AL – 4V ELI is an alloyed titanium product containing 6% Aluminum and 4% Vanadium, ELI (Extra Low Interstitial).

6AL–2Sn–4Zr–2Mo (6-2-4-2) is an alloyed titanium product containing 6% Aluminum, 2% Tin, 4% Zirconium, 2% Molybdenum.

6AL–6V–2Sn (6-6-2) is an alloyed titanium product containing 6% Aluminum, 6% Vanadium, 2% Tin.

5AL–2.5Sn & ELI (5-2.5) is an alloyed titanium product containing 5% Aluminum and 2.5% Tin. Also ELI (Extra Low Interstitial).

8AL–1V–1Mo (8-1-1) is an alloyed titanium product containing 8% Aluminum, 1% Molybdenum and 1% Vanadium.

15V–3Cr–4AL–3Sn (15-3-3-3) is an alloyed titanium product containing 15% Vanadium, 3% Chromium, 4% Aluminum, 3% Tin.

Company Introduction

Baoji City Changsheng Titanium Co.,Ltd

Is established in 2006, located in Baoji City which is know as the"Titanium City". At present, we have complete production lines of metallic titanium and titanium alloy materials, with 9 engineers, 20 advanced artificers, and 30 production artificers. As a professional manufacturer, specialized in Titanium and Titanium alloys. Our main products are Titanium bars, forgings; Titanium tubes, Titanium large diameter seamless pipes and other nonferrous metals.

Our quality management system is in accordance with ISO9001:2008 standard, which effectively guarantees the quality and delivery of the products.From 2011,we have honor to be the gold supplier of Alibaba.com.Meanwhile,we are certificated manufacturer by BV and TUV.

Is established in 2006, located in Baoji City which is know as the"Titanium City". At present, we have complete production lines of metallic titanium and titanium alloy materials, with 9 engineers, 20 advanced artificers, and 30 production artificers. As a professional manufacturer, specialized in Titanium and Titanium alloys. Our main products are Titanium bars, forgings; Titanium tubes, Titanium large diameter seamless pipes and other nonferrous metals.

Our quality management system is in accordance with ISO9001:2008 standard, which effectively guarantees the quality and delivery of the products.From 2011,we have honor to be the gold supplier of Alibaba.com.Meanwhile,we are certificated manufacturer by BV and TUV.

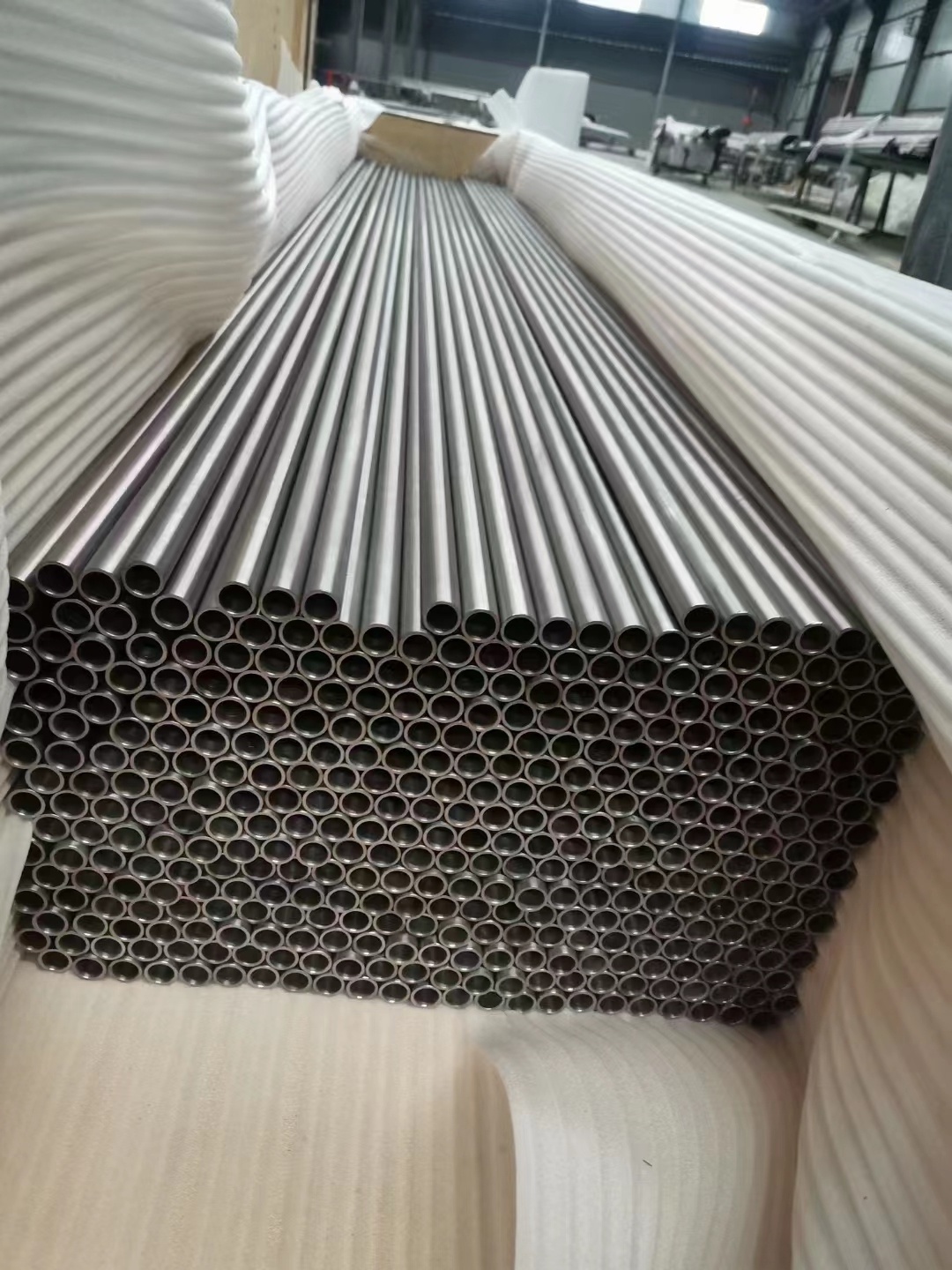

Quality Control

1. The workshop strictly follows the iso9001-2015 production standard

2. We make sure the raw material is 100% titanium sponge, we will supply the raw matrial Chemical composition certificate

3. Every bar will do size, surface and 100% UT test before shipping

4. Business license of product testing institution

Packing&Shipping

1. Before shipping we will supply the picture of your product for your reference.

2. Supply 3.1 MTC test report

3. We can also accept SGS or BV test at our factory

4. Packing: Standard export wooden case or as your request

5. By Air, By Sea, By Train, By express we will choose the best and cheaper shipping way for you

Contact Us

FAQ

1.Are you the manufacturing or trading company?

Real manufacturing company, started from 2001, nearly 20 years. With 2 sales teams for foreign trading business, started from 2008, more than 10 years experiences.

-------------------------------------------------------------------------------

-------------------------------------------------------------------------------

2.Do you have a dedicated R & D team? Can you

design a product for us? We have a dedicated technical team responsible for research and development. But most of titanium

fittings are standard, we can follow ASTM B363 / ASME SB363 or other you asked.

-------------------------------------------------------------------------------

design a product for us? We have a dedicated technical team responsible for research and development. But most of titanium

fittings are standard, we can follow ASTM B363 / ASME SB363 or other you asked.

-------------------------------------------------------------------------------

3.Can you provide samples? Is there a charge?

Samples can be provided for a fee.

Samples can be provided for a fee.

-------------------------------------------------------------------------------

4.What is your payment method?

We can accept T / T, LC, trade assurance order from alibaba.com. Samples are 100% prepaid. Orders for mass

production are below 5000 USD, 100% prepaid, above 5000 USD, 30% prepaid, and 70% paid before delivery.

-------------------------------------------------------------------------------

production are below 5000 USD, 100% prepaid, above 5000 USD, 30% prepaid, and 70% paid before delivery.

-------------------------------------------------------------------------------

5.How long is your delivery time? Inventory

samples: within 3 working days Products for bulk orders: 25-30 days under normal circumstances.

-------------------------------------------------------------------------------

samples: within 3 working days Products for bulk orders: 25-30 days under normal circumstances.

-------------------------------------------------------------------------------

6.After-sales products, how to deal with problems?

Based on our statistics for each year, the probability of problems with titanium products is around 0.8%. There are two main reasons for the problem:

Based on our statistics for each year, the probability of problems with titanium products is around 0.8%. There are two main reasons for the problem:

1) Among the products that have problems, 93% are misplaced in pre-sales communication, and the product

that the customer needs is not really clear.

that the customer needs is not really clear.

2) 5% is an unexpected situation and the extension of the construction period.

3) 2% is the problem of transportation and packaging. During long-distance transportation, the packaging is damaged and the surface is damaged.

-------------------------------------------------------------------------------

7.What is your company's response to the product in question?

1) Verify and blame for pre-sales communication issues. Compensation is handled according to the proportion

of liability.

of liability.

2)We are 100% responsible for problems caused by damaged packaging during transportation.

Hot Searches