- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

CH-2017-N-00128

-

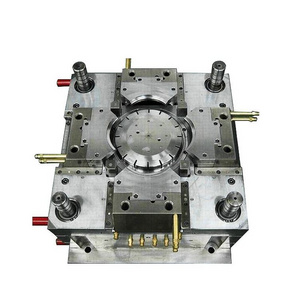

Mold Steel:

-

P20, 2738, 718H, H13, S136,NAK80

-

Sprue Gate:

-

Pin-Point Gate,Valve Gate,Edge Gate,Submarine Gate

-

Runner:

-

hot runner, cold runner, hot & cold runner

-

Ejector Type:

-

Ejection Pin, Stripper and ejector Plate, Hydraulic and Air Cylinder

-

Mold Cavity:

-

1,2,3,4,6, 8,12,16, 24,32

-

Product material:

-

PP, PE, PC, PS, PA, ABS, PVC

-

Surface Treatment:

-

Rattan Design, Polish, Etched, Texture, Nitrating, Chromed

-

Product Release:

-

Auto Drop, Mechanical, Manual

-

Certification:

-

Supplier Assessment

-

Name:

-

spanking machine plastic shell mould

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

CH MOULD

-

Model Number:

-

CH-2017-N-00128

-

Mold Steel:

-

P20, 2738, 718H, H13, S136,NAK80

-

Sprue Gate:

-

Pin-Point Gate,Valve Gate,Edge Gate,Submarine Gate

-

Runner:

-

hot runner, cold runner, hot & cold runner

-

Ejector Type:

-

Ejection Pin, Stripper and ejector Plate, Hydraulic and Air Cylinder

-

Mold Cavity:

-

1,2,3,4,6, 8,12,16, 24,32

-

Product material:

-

PP, PE, PC, PS, PA, ABS, PVC

-

Surface Treatment:

-

Rattan Design, Polish, Etched, Texture, Nitrating, Chromed

-

Product Release:

-

Auto Drop, Mechanical, Manual

-

Certification:

-

Supplier Assessment

-

Name:

-

spanking machine plastic shell mould

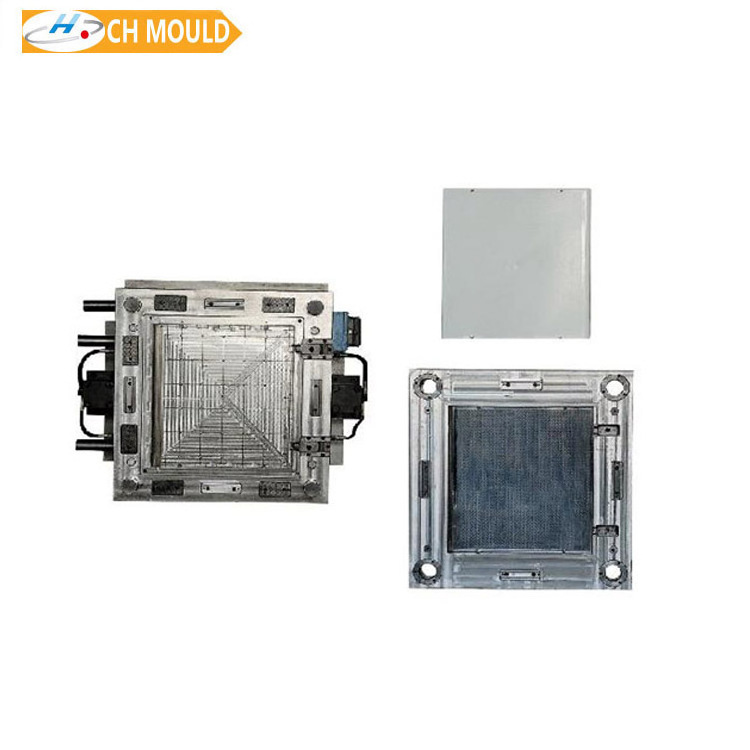

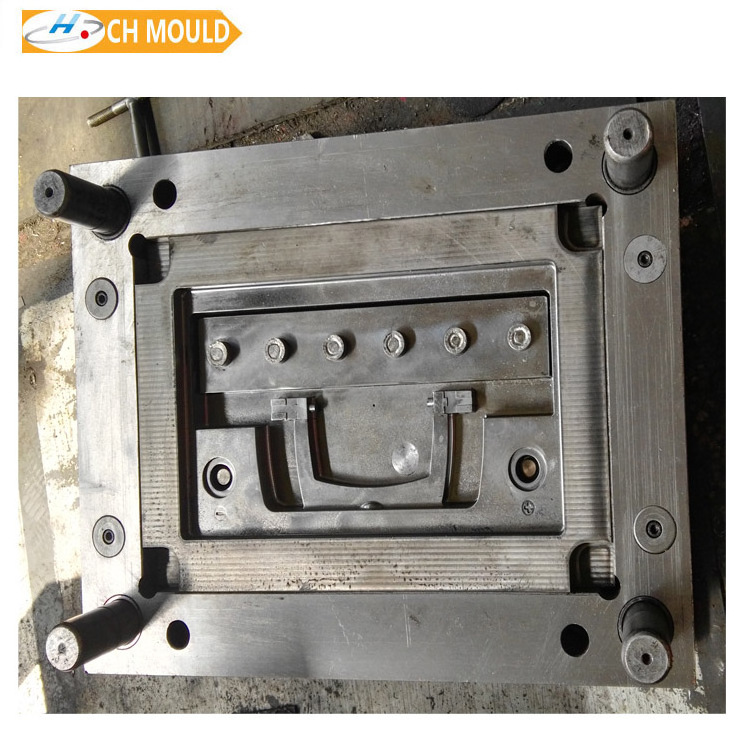

Manufacturing multi tool spanking machine plastic shell mould

|

Product Name |

Manufacturing multi tool spanking machine plastic shell mould |

|

|

Product material |

PP |

|

|

Core& Cavity Steel |

P20 |

|

|

Steel hardness: |

HRC35 |

|

|

Mould Base |

45# |

|

|

Cavity Number |

1 |

|

|

Injection System |

side gate, Hot runner |

|

|

Ejector System |

ejector pins and hydraulic |

|

|

Cycle Time |

50 second/shot |

|

|

Tooling lead time |

50 days |

|

|

Mould life |

600, 000 times |

|

|

|

|

|

|

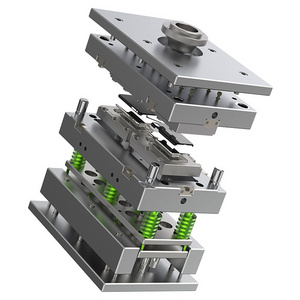

Why Choose us ?? Because we have those advantage |

1. We are moulds manufacturer s |

|

|

2. Competitive price |

||

|

3. High mould quality with guaranteed |

||

|

4. On time delivery |

||

|

5. Strict quality control |

||

|

6. All the mo uld produced follow on customers’ requirements |

||

|

|

||

|

We can offer you |

Professional & detailed response |

|

|

In time complete quotation |

||

|

P rofessional and integrity designs & drawings Mold flow analysis report |

||

|

Once a week mould process machining |

||

|

In-time mould test and sample delivery |

||