- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

65 kg

-

Application:

-

plastic injection mold ultrasonic cleaning

-

Tank capacity:

-

30L or Customized

-

Ultrasonic Power:

-

digital generator

-

Keyword:

-

mould electrolytic ultrasonic cleaner

-

Tank Material:

-

ss304 or ss316

-

Type:

-

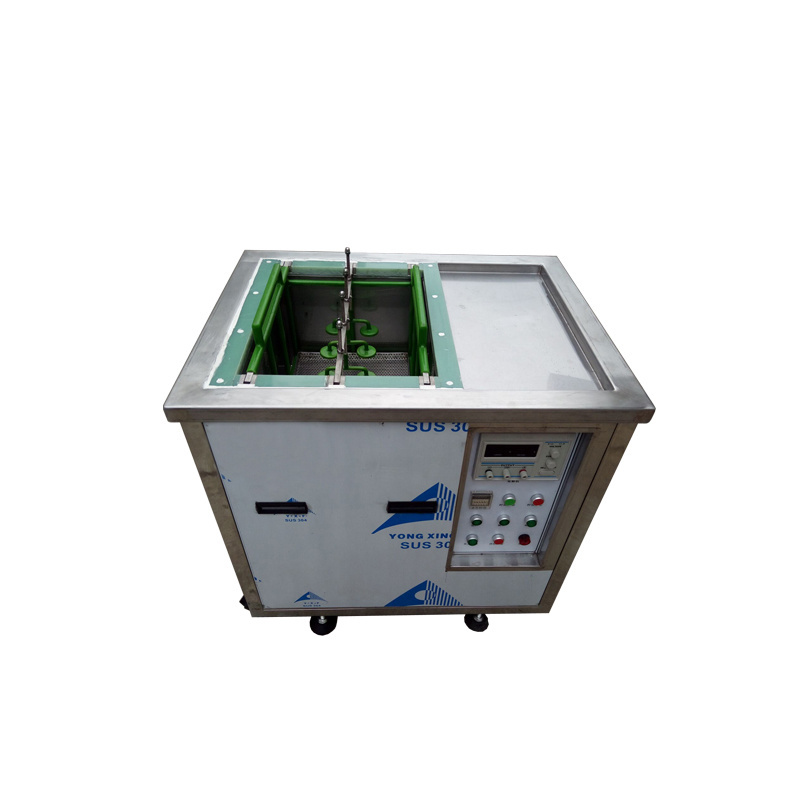

Ultrasonic Mold Washing System

-

Function:

-

Gold type cleaning / running water cleaning / anti-rust engineering

-

Frequency:

-

28K Or 40K

-

Heating power:

-

1500w

Quick Details

-

Core Components:

-

ultrasonic generator

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Pulisonic

-

Weight (KG):

-

65 kg

-

Application:

-

plastic injection mold ultrasonic cleaning

-

Tank capacity:

-

30L or Customized

-

Ultrasonic Power:

-

digital generator

-

Keyword:

-

mould electrolytic ultrasonic cleaner

-

Tank Material:

-

ss304 or ss316

-

Type:

-

Ultrasonic Mold Washing System

-

Function:

-

Gold type cleaning / running water cleaning / anti-rust engineering

-

Frequency:

-

28K Or 40K

-

Heating power:

-

1500w

The mold ultrasonic cleaning machine is also called the electrolytic ultrasonic mold cleaning machine, which is a kind of electrolytic cleaning machine. The mold cleaning machine is mainly composed of an ultrasonic generator system, an electrolytic circuit system, a circulating filter system, a special gold type cleaning fluid and a water-based rust inhibitor. The ultrasonic cleaning machine uses a water-based solvent as a cleaning agent, which is mainly suitable for mold removal Cleaning of oil stains, dust removal, stripping agent and electroplating parts before and after plating. It has a good cleaning effect for the removal of oil stains on various hardware and mechanical parts.

Principle of the electrolytic mold cleaning machine: electrolysis is the process of chemical decomposition of substances under the action of electric current. During the electrolysis process, the dirt on the metal surface begins to fall off, and the peeling is accelerated under the impact of ultrasonic waves. The metal surface is stained with animal and vegetable oils, minerals Oil, paraffin, carbon deposit, oxide layer. Use electrolysis to remove these dirt. When the current passes through the mold electrolytic cleaning agent containing a special formula, oxygen is generated near the positive electrode of the electrolytic cell, and hydrogen is generated at the negative electrode. Put the metal parts to be cleaned into the positive electrode of the electrolytic cell, and there will be fines on the metal surface during the electrolysis process. The hydrogen gas is produced, and these small bubbles promote the peeling of the dirt from the metal surface. Ultrasonic cleaning is a process in which a 40KHZ high-frequency power supply is used to convert the transducer from electrical energy to mechanical energy. During this process, the transducer transfers huge energy to the cleaning tank solution. , Generate positive and negative pressure zones in the liquid, forming tens of thousands of cavitation bubbles, which continue to form explosions, impact the surface of the cleaned metal object, and quickly release the dirt on the metal surface. To clean the mold and restore the mold True color.

Advantages of mold ultrasonic cleaning machine:

1. The electrolytic cleaning system emits gas to the metal surface, and uses the sauna cleaning effect to remove the dirt, impurities, and sundries on the metal surface. It can also completely remove resin components and moisture; through ultrasonic vibration, the dirt peels off and floats, and the metal is attached to the cathode. Even the dirt in the dead corner can be completely removed.

2. Restore the metal to the original copper-green color and restore the original beauty of the metal.

3. Even complex shapes can remove dirt.

4. It can achieve the purpose of cleaning and decontamination.

5. It has a good rust removal and antirust effect.

6. Generally speaking, it takes about an hour to save time than manual cleaning.

7. It is more environmentally friendly and safer than using organic solvents.

8. It can greatly reduce the defective rate after washing.

9. This cleaning machine has a long service life, generally at least five years.

10. The purchase cost and use cost of the whole machine are relatively reasonable.

Electrolytic ultrasonic cleaning process description: gold type washing → running water washing → anti-rust project.

Scope of application of mold ultrasonic cleaning machine:

1. Mold types: injection molds, instrument precision molds, connector molds, precision seal molds, stamping molds, forming molds, etc.

2.Mold gas residue layer, sulfide formed at high temperature, fireproof plastic residue, toner residue, mold surface oxide, and various mold rust stains, oil stains, etc.

|

Type |

Frequency (Khz) |

Power(W) |

Capacity(L) |

|

PLS-MJQXJ-30LTT |

28KHZ,40KHZ |

1500 |

30 |

|

PLS-MJQXJ-50LTT |

28KHZ,40KHZ |

2500 |

50 |

|

PLS-MJQXJ-70LTT |

28KHZ,40KHZ |

3500 |

70 |