Aluminized Steel Pipe for Automotive application like as Muffler tube of Exhaust Systems, Cylinder tube of Shock absorber and Steering parts etc.

- Product Details

- {{item.text}}

Quick Details

-

Material:

-

DX53D/SA1D

-

Aluminum coating:

-

80/120g

-

Technology:

-

High Frequency Welding

-

Packing:

-

In bundles

-

Application:

-

Automotive Exhaust System

-

Size:

-

25mm-127mm

-

Thickness:

-

1.0/1.2/1.5/2.0mm

-

HS Code:

-

7306309

-

Delivery time:

-

15-30Days

Quick Details

-

Brand Name:

-

MX Exhaust

-

Place of Origin:

-

China

-

Product:

-

Aluminized Exhaust Steel Pipe

-

Material:

-

DX53D/SA1D

-

Aluminum coating:

-

80/120g

-

Technology:

-

High Frequency Welding

-

Packing:

-

In bundles

-

Application:

-

Automotive Exhaust System

-

Size:

-

25mm-127mm

-

Thickness:

-

1.0/1.2/1.5/2.0mm

-

HS Code:

-

7306309

-

Delivery time:

-

15-30Days

Product Description

High Performance Aluminized Steel Pipe/Tube with Aluminum Coating 80/120 GRM/M2

DIAMETERS: 43, 45, 47.15, 50, 55, 60, 63.5, 76, 88.9, 101.6, 114, 127MM

Raw Material: Superior Quality by POSCO or VAMA in China

Quality: DX53D/SA1D

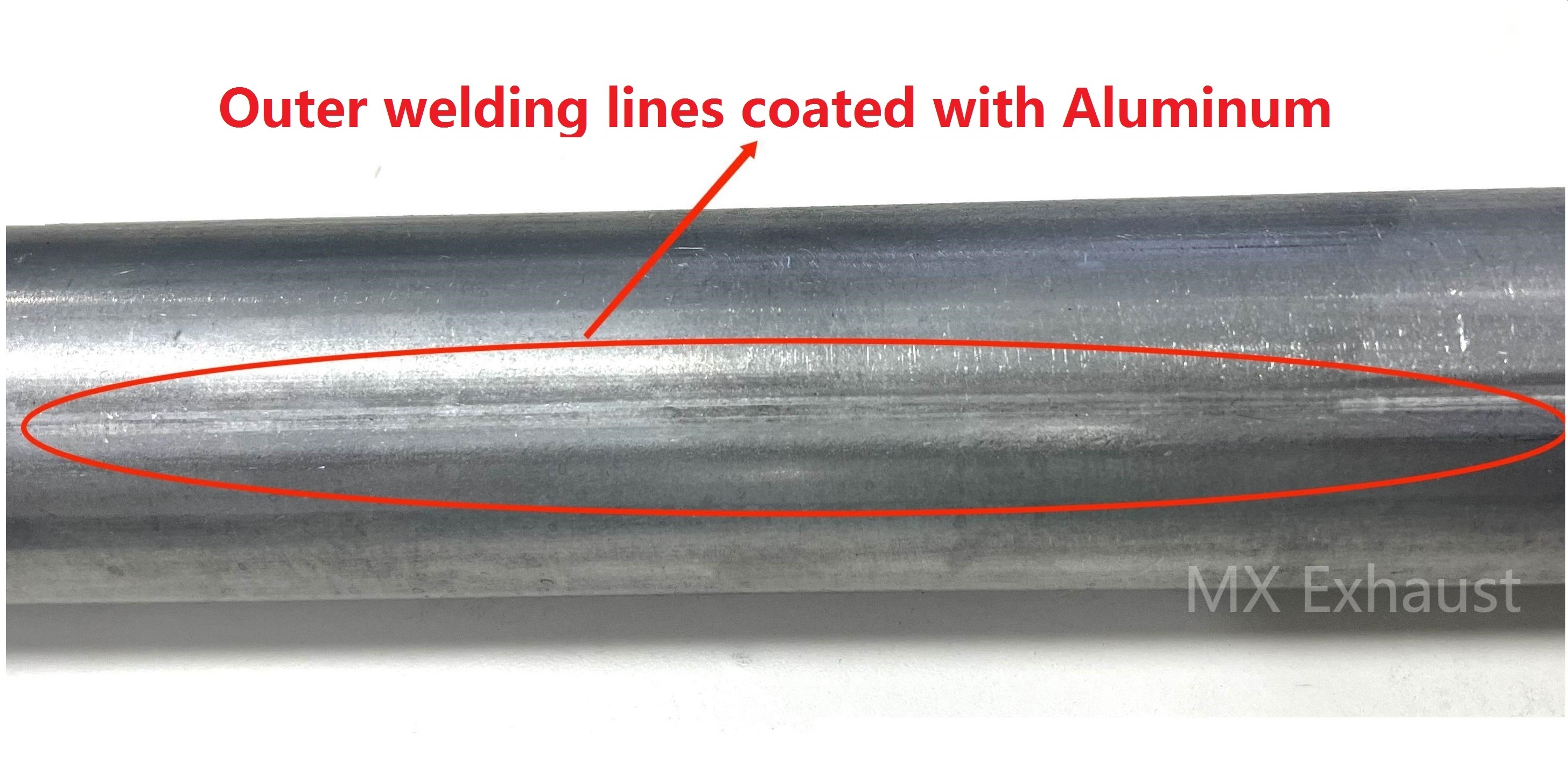

Made by High Frequency Welding Machine

Main Applicaton Scope:

Aluminized Steel Pipe used for Automotive application like as Muffler tube of Exhaust Systems, Cylinder tube of Shock absorber and Steering parts ect.

Our Product Features:

1. Inside and Outside Bead Scarfing

2. Outside Metallizing for Aluminum Coated Pipes

3. Higher Expansion Rate

4. Smooth Surface Roughness

5. Accurate Roundness

6. Superior Bending Quality

Aluminized Steel Pipe used for Automotive application like as Muffler tube of Exhaust Systems, Cylinder tube of Shock absorber and Steering parts ect.

Our Product Features:

1. Inside and Outside Bead Scarfing

2. Outside Metallizing for Aluminum Coated Pipes

3. Higher Expansion Rate

4. Smooth Surface Roughness

5. Accurate Roundness

6. Superior Bending Quality

|

Item Name

|

Aluminized Steel Pipe SA1D with aluminum coating 60/60grm/m2

|

|

Standard

|

JIS G3445

|

|

Material

|

SA1D/DX53D

+ AS60/60 GRM/M2

|

|

Out Diam

|

19/25.4/35/38/40/42.7/44/45/47.15/50/50.8/51/54/55/57.15/58/60/60.5/63/76.2/88.9/101.6/114/127MM, or as customizable

|

|

Wall Thickness

|

1.0/1.2/1.4/1.5/1.6/2.0/2.5MM

|

|

Length

|

1M, 2M, 3M, 5.8M, 6M or as customizable

|

|

Technolgy

|

ERW/HFW

|

|

Packing

|

In bundle or Woodern Carton

|

|

Delivery time

|

10-25 Days

|

|

Place of Origin

|

Shandong, China

|

|

Brand Name

|

MX Exhaust or customizable

|

|

Quality

|

Superior and Stable

|

|

Application

|

Gas Pipe, Exhaust system, exhaust muffler, cylinder pipe of shock absorber, Steering parts

|

|

Alloy Or Not

|

Non-Alloy

|

|

Section Shape

|

Round

|

|

Certificate

|

ISO 9001

|

|

Tolerance

|

±5%

|

|

Processing Service

|

Welding, Punching, Cutting, Bending

|

|

Oiled or Non-oiled

|

Slightly Oiled

|

|

Price terms

|

EXW/FOB/CIT/CFR

|

|

HS Code

|

7306309

|

Product Paramenters

Details Images

Packing & Delivery

WHY CHOOSE US? WHAT WE CAN DO ?

We are the biggest Professional manufacturer in China for ERW Aluminized Steel Pipe DX53D/SA1D, AS80 or AS120.

Various pipe modles for Aluminized pipes can be provided. If you need, pls do not hesitate let us know!!!

We manages 1 ERW(High Frequency Welding Machine) pipe manufacturing line,, 26 pipe manufacturing lines, 43 units of bent pipelines, 18 automatic welding lines, 4 decorative tail pipe lines and other production lines, along with more than 800 diverse equipment and facilities.

1). Founded in 2001 and experienced in the field of exhaust system and industrial pipe for 20+ years.

2). Management system certification: ISO9001, TSI16949

3). Sales network expends from over domestic sales to all over the world.

Our Advantages

High Frequency Welding Machine(HFW/ERW)

Under HFW Welding lines, our production capacity is 24mt/8 hours, the welding speed is 60meters/Miniute and the welding quality is

stable. When production, Inside and Outside Bead Scarfing, Outside Metallizing for Aluminum Coated Pipes, and Eddy current tesing while production.

stable. When production, Inside and Outside Bead Scarfing, Outside Metallizing for Aluminum Coated Pipes, and Eddy current tesing while production.

Abundant Raw materia

l from POSCO or VAMA, High Technical Welding methords and the superior raw material enabling for the pipes welding points won't broken when end-user making bend tubes or spinning tube.

Recommend Products

Hot Searches