* Lightweight

* Excellent impact and compressive resistance;

* Costless and energy-saving;

|

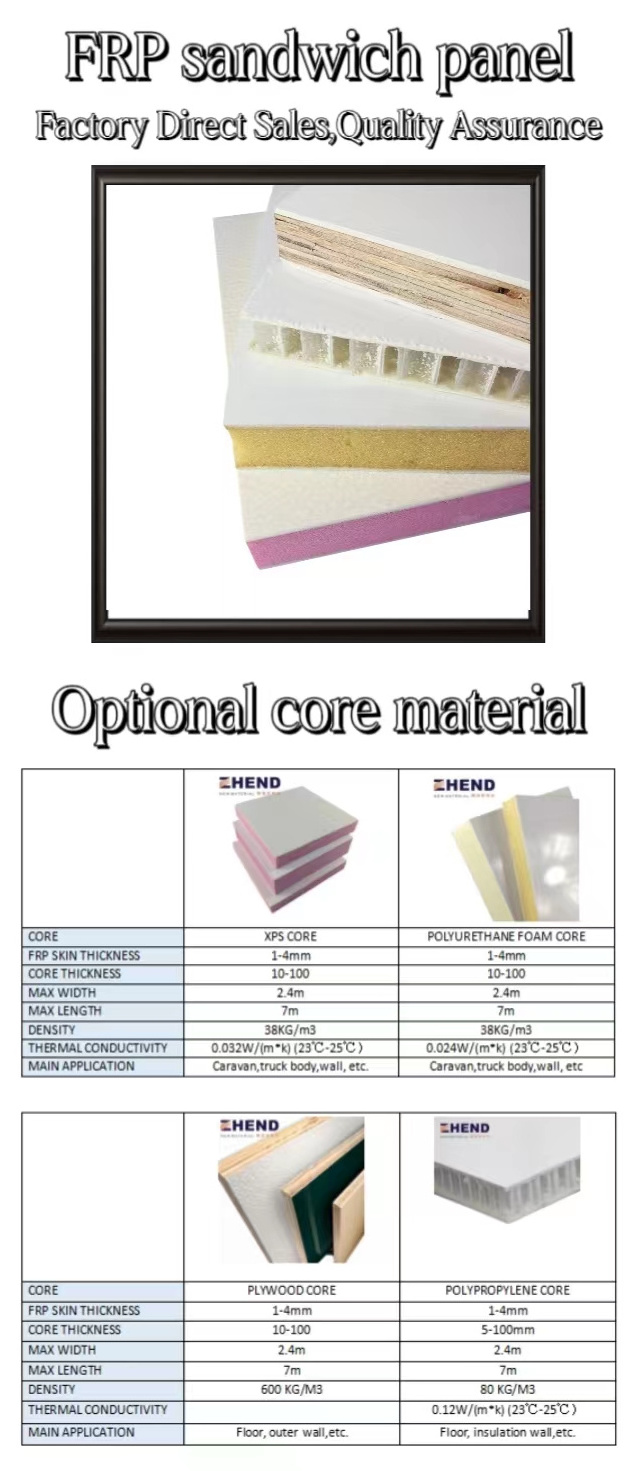

Type

|

PU/XPS Foam/ PP hoenycomb/ Plywood Sandwich Panels

|

|

Width

|

Max 2.7m

|

|

Thickness

|

Skin: 0.6mm~4mm

Core: 10mm-100mm |

|

Length

|

Custom-made

|

|

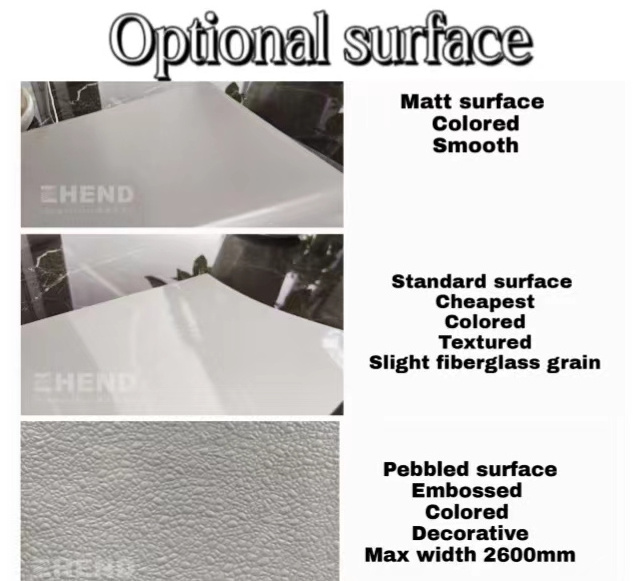

Skin

|

FRP Sheet,

|

|

Color

|

White, black, green, yellow, customized

|

|

Application

|

RVs, trailers, vans, refrigerated trucks, campers, caravans, motorboats, mobile homes, clean rooms, cold rooms, etc.

|

|

Custom-Made

|

CNC service

|