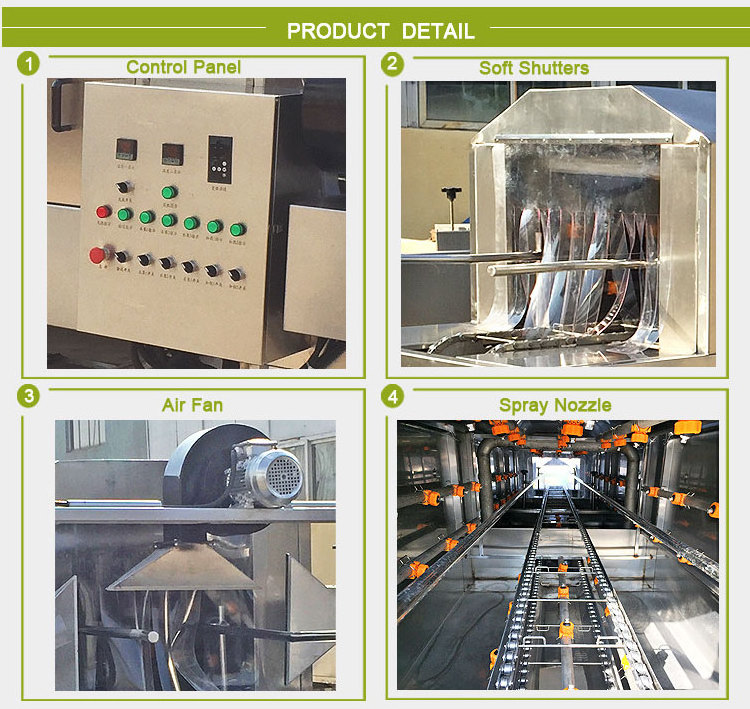

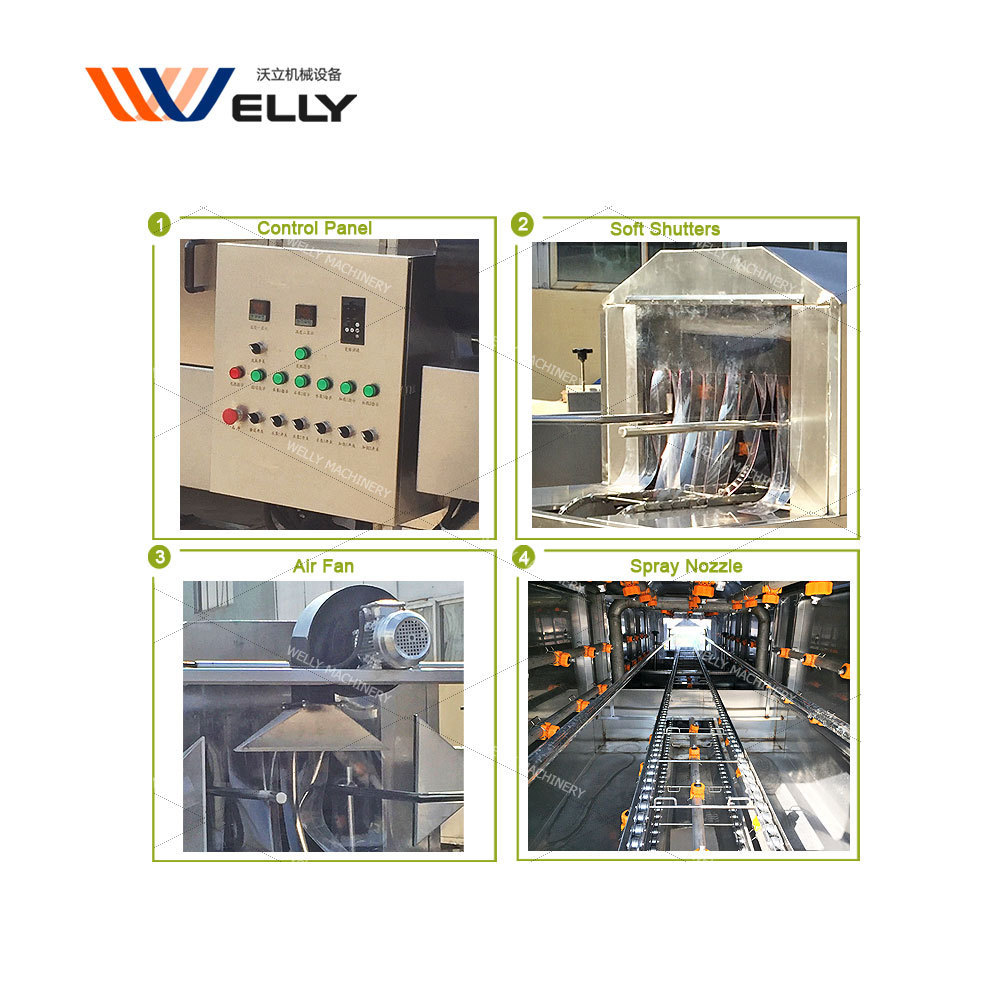

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

WELLY

-

Material:

-

Plastic/ Glass / Ceramic, SUS304

-

Weight (KG):

-

700 kg

-

Product Name:

-

bin cleaning machine

-

Capacity:

-

200-300pcs/h

-

Inner width:

-

800mm

-

Through width:

-

600mm

-

Heating temperature:

-

Normal temperature to 80°C (adjustable)

-

High pressure cleaning:

-

5kg pressure hot water cleaning

-

Conveying speed:

-

0.7-7m/min

-

Usage:

-

Cleaning Plastic Box

-

Key words:

-

Tray, crate, box, basket washing

Quick Details

-

Cleaning Process:

-

Cold/ Hot Water Cleaning

-

Power:

-

14.6kw

-

Max. Pressure:

-

Other

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

WELLY

-

Material:

-

Plastic/ Glass / Ceramic, SUS304

-

Weight (KG):

-

700 kg

-

Product Name:

-

bin cleaning machine

-

Capacity:

-

200-300pcs/h

-

Inner width:

-

800mm

-

Through width:

-

600mm

-

Heating temperature:

-

Normal temperature to 80°C (adjustable)

-

High pressure cleaning:

-

5kg pressure hot water cleaning

-

Conveying speed:

-

0.7-7m/min

-

Usage:

-

Cleaning Plastic Box

-

Key words:

-

Tray, crate, box, basket washing

♦ Fast Delivery Automatic Baking Drip Tray Plastic Crates Washing Trash Bin Plastic Box Plastic Tray Washer Bin Cleaning Machine

| Technical Data | ||||||

| Model | Power | Capacity | Through width | Heating temperature | Conveying speed | Machine size |

| WYXK-4000 | 10.25kw | 200-300pcs/h | 600mm | Normal temperature to 80°C (adjustable) | 0.7—7m/min | 4200x1200x1600mm |

| WYXK-6000 | 15.35kw | 300-500pcs/h | 6200x1200x1600mm | |||

Brief Description:

1. The machine is washed with high-pressure and high-temperature water. The high-pressure water pump circulates the boiling water in the water tank to the spray pipe, and sprays it from the nozzle on the spray pipe to form a high-pressure high-temperature water flow cleansing turnover box, which flushes the dirt away from the surface of the turnover box.

2. Varied cleaning solvents can be added during the cleaning process to enhance the cleaning effect. Except for the motor and the nozzle, the machine is made of SUS 304 stainless steel. The nozzle adopts a temperature-resistant quick-disconnecting plastic fan-shaped nozzle, and the brush is made of food-grade nylon wire material.

3. The washing water tank is divided into two groups, each with a filtering device. The clean water source can be reused. The nozzle cleans the basket from four directions, and the multi-pass cleaning guarantees that the surface is clean. The sides of the cleaning room are movable waterproof doors, and the soft shutters at both ends are sealed and waterproof, which is convenient for equipment maintenance and maintenance.

Washing Process:

1. The basket to be cleaned is input into the washing machine by a stainless steel chain, and the basket is cleaned by high-temperature alkaline water→high-pressure hot water→normal temperature tap water; continuous cleaning is used to improve the cleaning efficiency.

2. Washing is divided into three sections.

The first section is hot alkaline water, the second section is hot water, and the third section is tap water. In addition to the third section of tap water, the three sections of spray water have independent circulating filtered water tanks. After the heating water is used, part of the sewage is automatically discharged. The second water tank is provided with a heating pipe, and the temperature is freely set from normal temperature to 80 °C. The third section water is independent of clean water from the water tank at the bottom to ensure that it is clean water, unaffected by other tanks, the dirty water is flushed through this section.