1. Paper Roll Film Slitting Rewinding Machine The frame adopts thickened room tube

2. Low noise, stable operation and high output, the output of a single machine can be used by 3 coilers.

3. Thermal Paper Roll Slitting Rewinding Machine Both sides of the cut paper tape are smooth and flat without burrs.

4. Paper Cutting Machine The knife holder shaft wallboard is installed in one piece, which improves the precision and stability of the knife shaft.

5. The unloading method adopts open unloading, which is safer and more convenient.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 3P 50HZ

-

Power:

-

4800w, 4800w

-

Dimension(L*W*H):

-

1830*1690*1600mm

-

Weight:

-

485 kg

-

Marketing Type:

-

Hot Product 2023

-

Model:

-

ZM-250

-

Diameter:

-

100-320mm

-

Height:

-

30-250mm

-

Speer per hour:

-

300-500pcs/h

-

Air pressure:

-

4-6mpa

-

Physical dimension:

-

1830*1690*1600mm

-

Product name:

-

Gift Round Box Making Machine

-

Keyword:

-

Paper Cylinder Labeling Machine

-

Style:

-

Paper Can Assembling Machine With High Speed and Quality

Quick Details

-

Production Capacity:

-

300-500pcs/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZOMAGTC

-

Voltage:

-

380V 3P 50HZ

-

Power:

-

4800w, 4800w

-

Dimension(L*W*H):

-

1830*1690*1600mm

-

Weight:

-

485 kg

-

Marketing Type:

-

Hot Product 2023

-

Model:

-

ZM-250

-

Diameter:

-

100-320mm

-

Height:

-

30-250mm

-

Speer per hour:

-

300-500pcs/h

-

Air pressure:

-

4-6mpa

-

Physical dimension:

-

1830*1690*1600mm

-

Product name:

-

Gift Round Box Making Machine

-

Keyword:

-

Paper Cylinder Labeling Machine

-

Style:

-

Paper Can Assembling Machine With High Speed and Quality

Product Description

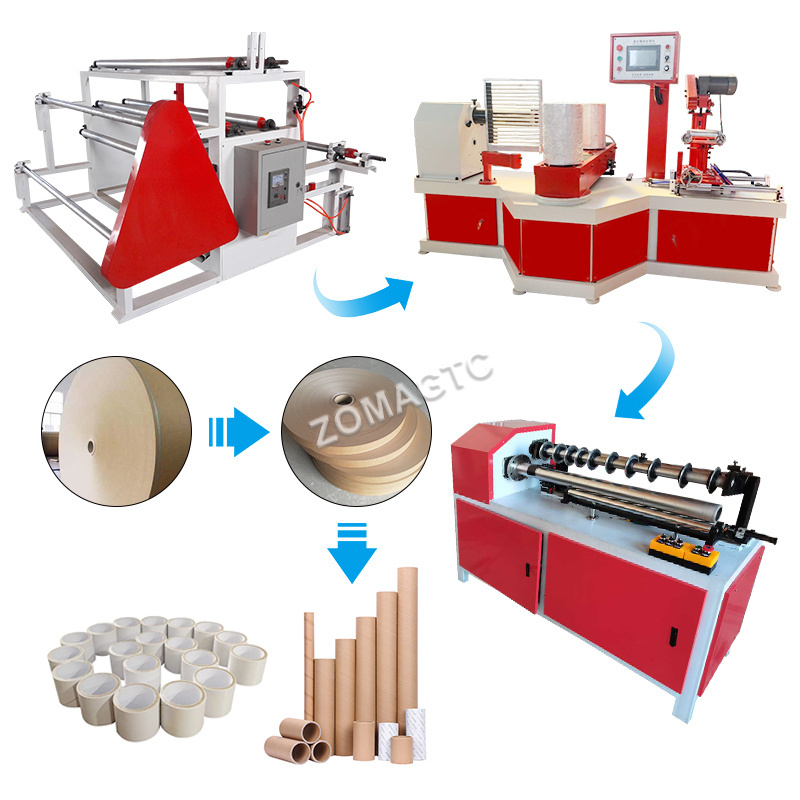

1. ZM-1600AB Paper Roll Slitter Machine

Thermal Paper Roll To Sheet Slitting Rewinding Machine Paper Roll Film Paper Cutting Slitting Rewinding Machine

|

Model

|

ZM-1600AB

|

|

Slitting speed (min)

|

300m

|

|

Slitting capacity

|

80g-600g

|

|

Minimum cutting width

|

40mm

|

|

base paper maximum width

|

1600mm

|

|

base paper maximum diameter

|

1200mm

|

|

Paper loading method

|

Pneumatic upper shaft

|

|

Winding method

|

Inflatable shaft AB shaft winding

|

|

monitor rate

|

4kw

|

|

Number of operators

|

1 person

|

|

cutting diameter

|

800mm

|

|

Number of cutters

|

21 pay

|

|

Host Specifications

|

2700×2300×1500

|

|

Speed control

|

Electromagnetic regulation

|

|

power supply

|

three phase

|

|

Weight

|

700kg

|

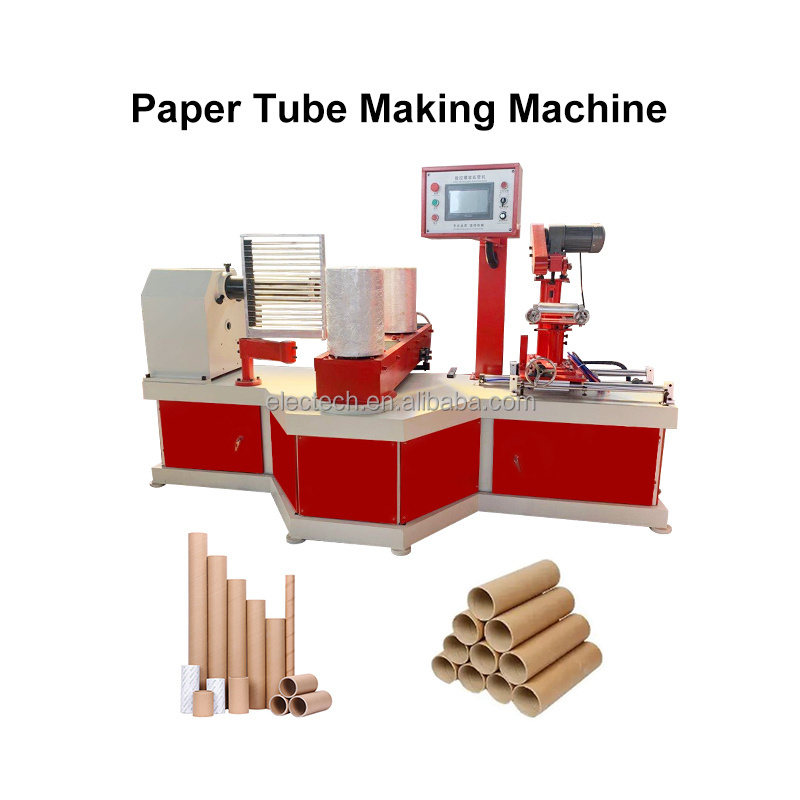

2. ZM-2150B/4250B Paper Tube Making Machine

|

1

|

The mainframe adopts heavy steel plate welded after CNC cutting, the machine is stable and not easy to deform. The main machine

adopts hard tooth surface full oil bath chain transmission, low noise. |

|

2

|

The mainframe adopts vector type High torque inverter speed regulation. PLC control system is used to improve cutting response

speed, cutting length control is more accurate than ever. |

|

3

|

With multi-function bottom paper supply device, paper breaking automatic paper stop function.

|

|

Model

|

ZM-2150B

|

ZM-4250B

|

|

Paper layer

|

3-16 layers

|

3-21 layers

|

|

Max. pipe diameter

|

150mm

|

250mm

|

|

Min.pipe diameter

|

20mm

|

40mm

|

|

Max.pipe thickness

|

8mm

|

20mm

|

|

Min.pipe thickness

|

1mm

|

1mm

|

|

Speed

|

3-20m/min

|

3-20m/min

|

|

Power

|

5.5KW

|

11KW

|

|

Voltage

|

380V 50Hz

|

380V 50Hz

|

|

Main machine size

|

2.8*1.8*1.95m

|

4.2*2*1.95m

|

|

Weight

|

1500kg

|

4200kg

|

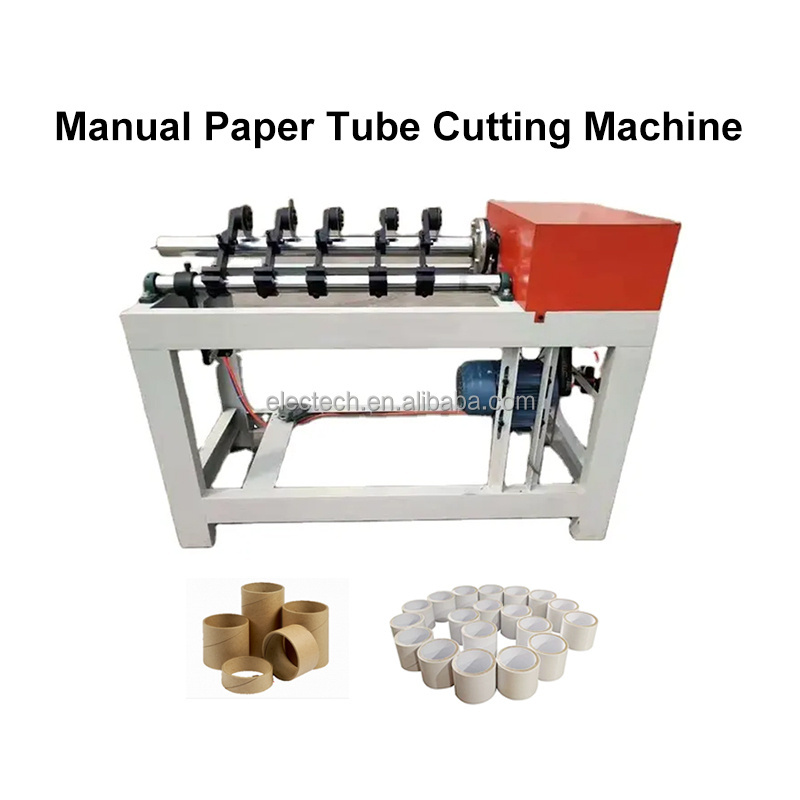

3.ZM-1000 Manual paper tube cutting machine

2.Paper Core Cutter The cutting tube diameter can be customrized

3.It comes with 5 blade for free

4.Spiral Cardboard Paper Tube Core Making Machine Easy to operate.

|

Model

|

ZM-1000

|

|

Max cutting length

|

1000mm(can be customrized)

|

|

Max cutting tube diameter

|

20-150mm(can be customrized)

|

|

Cutting speed

|

5-20m/min

|

|

Max cutting thickness

|

100mm(16ply)

|

|

Cutting blade distance

|

Can be adjustment

|

|

Voltage

|

220V,1.5KW

|

|

Weight

|

170kg

|

|

Size

|

1.2*0.5*1m

|

4. ZM Paper tube labeling machine

|

Model

|

ZM-250

|

|

Diameter

|

100-320mm

|

|

Height

|

30-250mm

|

|

Speer per hour

|

300-500pcs/h

|

|

Power

|

4800w

|

|

Air pressure

|

4-6mpa

|

|

Physical dimension

|

1830*1690*1600mm

|

|

Weight

|

485kg

|

|

Adjustment time

|

30-60min

|

The paper pot assembly machine adopts advanced forming technology to complete various forming processes, completely replacing manual operation procedures. The equipment is stable and the production efficiency is high. It can realize the operation of one person, one machine and liberate the labor force to a great extent. Save raw materials, low energy consumption. The structure runs smoothly, the forming is stable and the noise is low. Replacement of die is simple and fast.

1. Resolve the traditional multi-artificial flat-bottom paper tank assembly process.

1. Resolve the traditional multi-artificial flat-bottom paper tank assembly process.

2. Equipment automatically completes the internet folding bottom scratch of the label.

3. High efficiency, high stability and high quality, complete assembly work with high intelligence and unmanned operation.

3. High efficiency, high stability and high quality, complete assembly work with high intelligence and unmanned operation.

Recommend Products

Contact us

Contact Person: Amber Wang

Tel/Whats App/Wechat: +86 17788128163

E-mail: sales2@superelec.cn

Tel/Whats App/Wechat: +86 17788128163

E-mail: sales2@superelec.cn

Packaging & Shipping

|

Packaging Details

|

|

Stong wooden box package

|

|

|

Port

|

|

The main ports in China, depends customers choice

|

|

|

Lead Time

|

1 pc

|

35 days

|

|

|

|

>1 pcs

|

To be negotiated

|

|

SHIPPING

1.By air, sea or combined transportation.

2.Express via FEDEX, TNT, UPS, DHL, EMS(AS your request)

3.Tracking Number will offer you immediately after delivery

3.Tracking Number will offer you immediately after delivery

4.Shipping cost depends on the shipping method, product quantity,weight, carton size and your area.

Hot Searches