- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

MTF

-

Model Number:

-

MTF-M071

-

Product name:

-

Heat Sealing Bag Making Machine

-

Application:

-

Manufacturing Plant

-

Name:

-

Plastic Bag Heat Sealing Bag Making Machine

-

Function:

-

Multifunctional

-

Usage:

-

Making bag

-

Type:

-

Fully Automatic

-

Keyword:

-

Easy Operation

-

Voltage:

-

220V

-

Certification:

-

CE Certificate, CE

Quick Details

-

Machine Type:

-

SEALING MACHINE

-

Material:

-

Plastic

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

MTF

-

Model Number:

-

MTF-M071

-

Product name:

-

Heat Sealing Bag Making Machine

-

Application:

-

Manufacturing Plant

-

Name:

-

Plastic Bag Heat Sealing Bag Making Machine

-

Function:

-

Multifunctional

-

Usage:

-

Making bag

-

Type:

-

Fully Automatic

-

Keyword:

-

Easy Operation

-

Voltage:

-

220V

-

Certification:

-

CE Certificate, CE

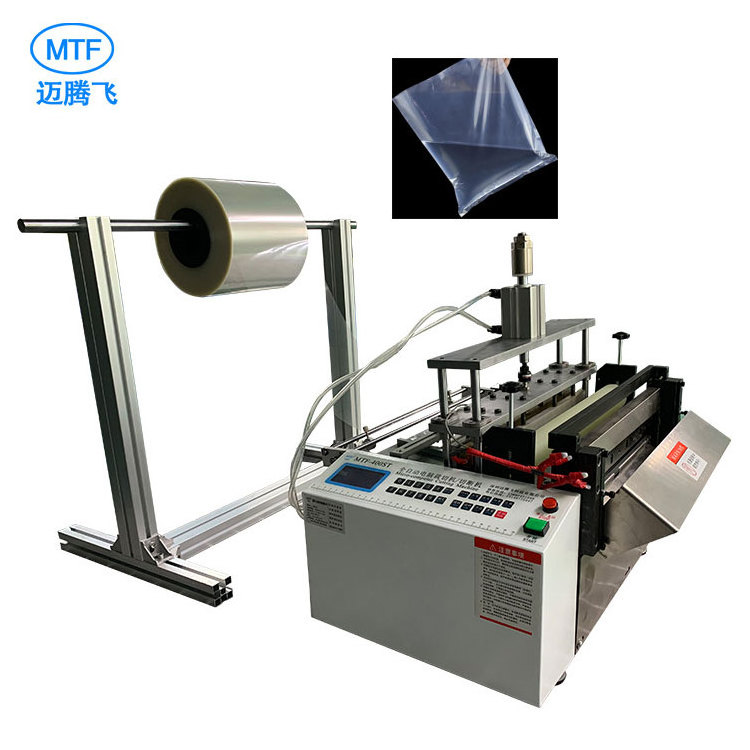

Products Description

|

Product model

|

MTF-M071

|

|

Product name

|

Hot press sealing machine cutting bag making machine

|

|

Product Power

|

220V/60HZ

|

|

Cutting length

|

0.1-9999.9mm

|

|

Cutting accuracy

|

40-120 PCS/min

|

|

Cutter material

|

Imported high quality steel knife

|

|

Application motor

|

Stepper motor + AC motor

|

|

Dimension

|

350*630*490mm

|

|

Weight

|

70kg

|

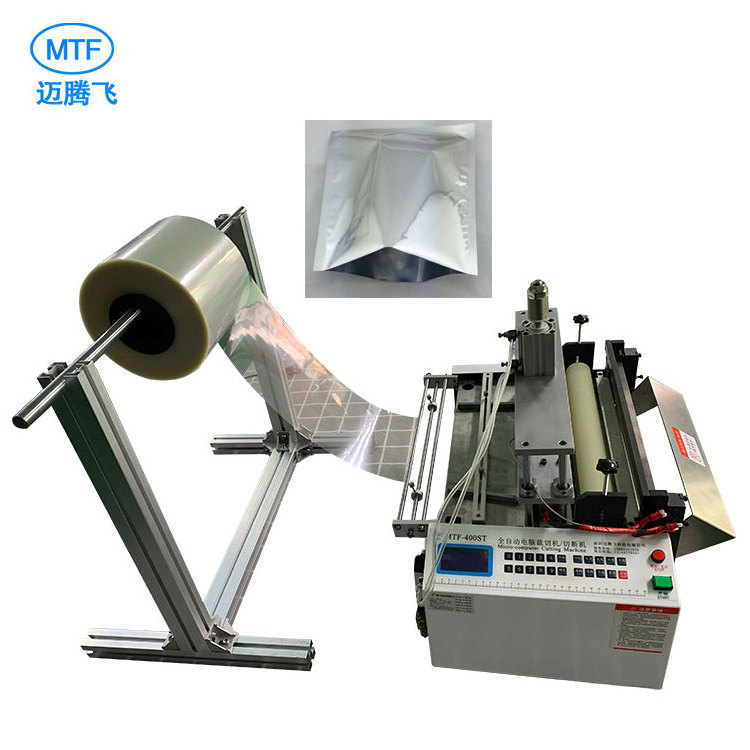

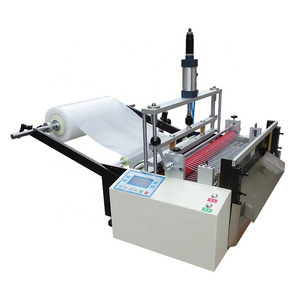

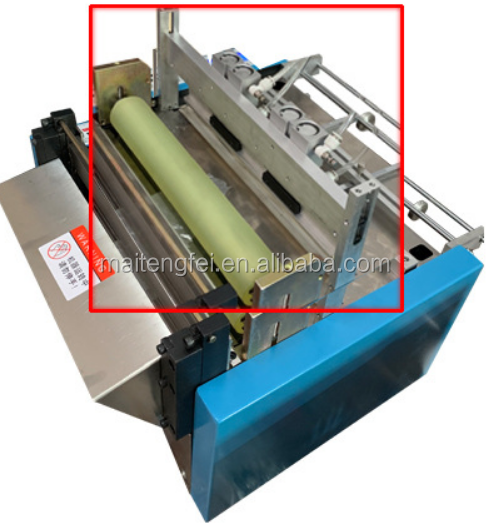

Hot-cut Sealing Bag Making Machine

PRODUCT DETAILS

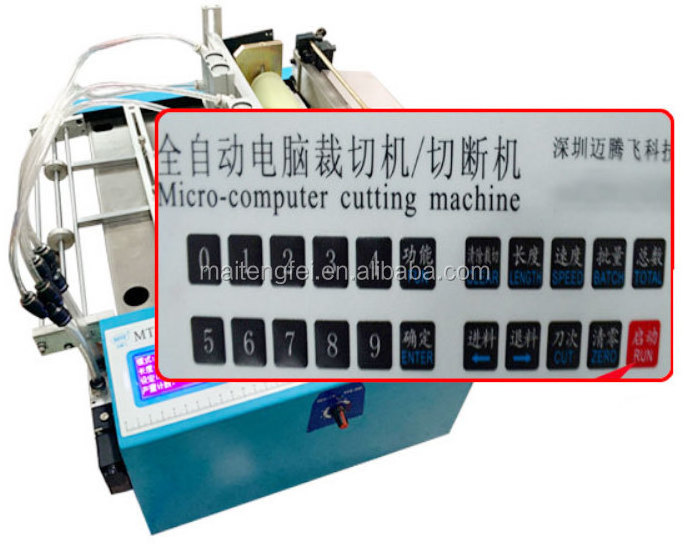

01 CONTROL PANEL

Microcomputer control system, LCD screen with all digital keys, simple operation, easy to set length, speed, batch, total

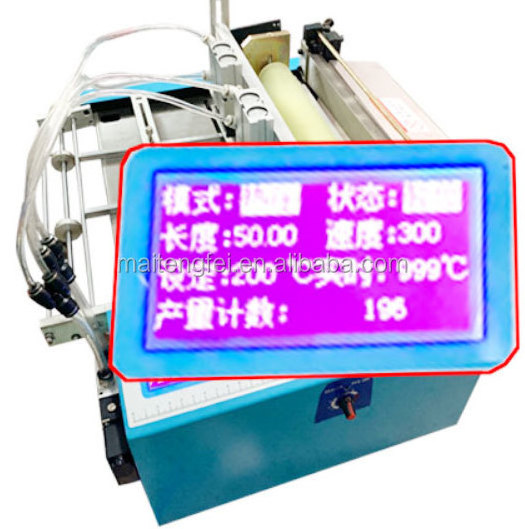

02 TEMPERATURE CONTROLLABLE

LCD display interface, you can grasp the machine temperature at a glance

03 SPECIAL TOOL

Imported high-quality steel knife, durable

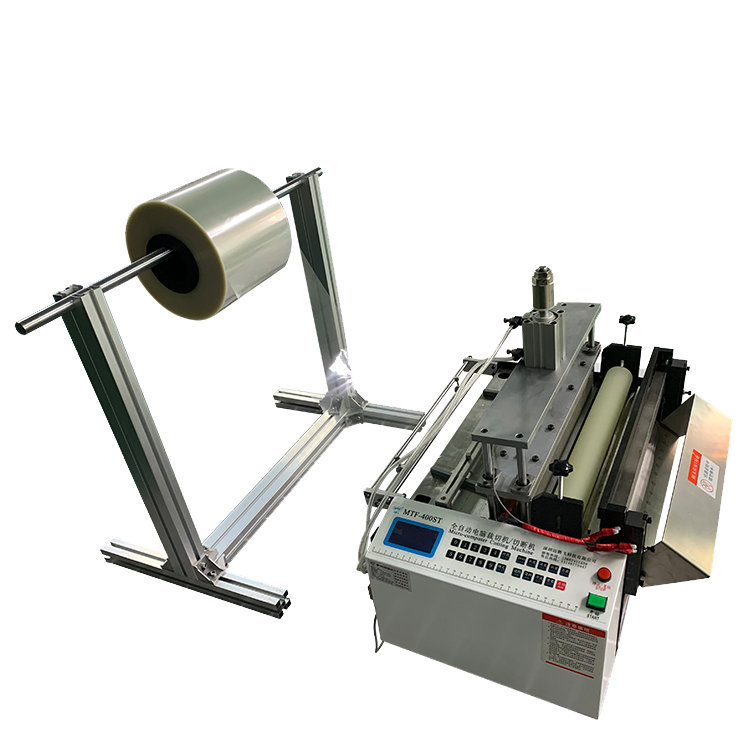

04 IMPORTED STEPPER MOTOR

High performance, special structure, high temperature resistance, motor output shaft is made of stainless steel

05 CYLINDER

Seal with hot knife

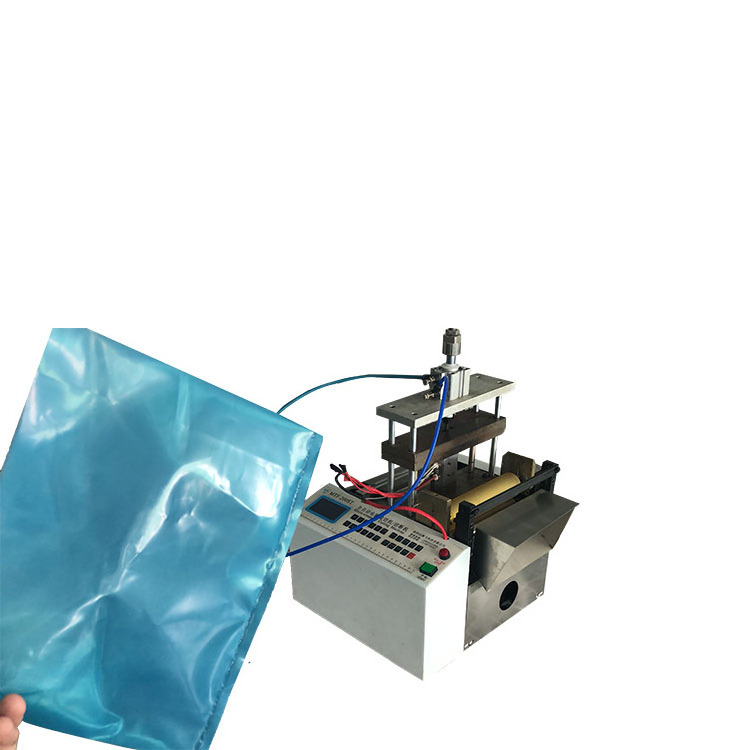

FINAL FINISHED PRODUCT

The machine can be made into material of flat pockets

Release paper PVC film PE film Plastic film Leather Self-adhesive paper Bubble film

Pearl cotton Opp Aluminum foil Non woven

Other papers Films and Cloths

PERFORMER CHARACTERISTICS

1. Using microcomputer control system, length/temperature/batch/cumulative can be adjusted in batch setting or delay setting, no special guard is needed, saving labor

2. Imported high-quality steel knives are used to ensure that the material is cut smoothly, wear-resistant and durable

4. Disassembly and assembly of the heating sealing device, suitable for various cutting materials

3. The design of the whole machine structure is reasonable, suitable for various cutting industries

PRODUCTION VIDEO

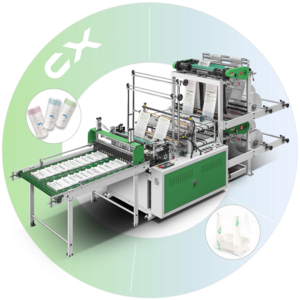

RELATED PRODUCTS

Hot Searches