- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

standard and customized

-

Application:

-

stamping of copper and aluminum sheets

-

Certificate:

-

ISO9001:2015

-

Product name:

-

Long Service Life Tungsten Carbide Bars Plates Strips

-

Usage:

-

stamping and cutting copper, aluminum and steel sheet.

-

Keywords:

-

Tungsten carbide sheet

-

Service:

-

ODM OEM

-

Material:

-

100% Virgin Tungsten Carbide

-

Delivery:

-

7-15 Days

-

Advantage:

-

Excellent hardness, high hardness, good wear resistance

-

Package:

-

Paper Carton

Quick Details

-

Alloy Specification:

-

K10 K20 K30 YG6 YG8 YG10

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

JINXIN

-

Model Number:

-

standard and customized

-

Application:

-

stamping of copper and aluminum sheets

-

Certificate:

-

ISO9001:2015

-

Product name:

-

Long Service Life Tungsten Carbide Bars Plates Strips

-

Usage:

-

stamping and cutting copper, aluminum and steel sheet.

-

Keywords:

-

Tungsten carbide sheet

-

Service:

-

ODM OEM

-

Material:

-

100% Virgin Tungsten Carbide

-

Delivery:

-

7-15 Days

-

Advantage:

-

Excellent hardness, high hardness, good wear resistance

-

Package:

-

Paper Carton

Product Description

Zhuzhou JinxinTungsten Carbide Plate

Performance features

* Non-destructive ultrasonic flaw detection, without sand hole and pore.

* Tungsten carbide plate is sintered by HIP-sinter furnace, greatly reduce porosity, enhance compactness.

* Effectively prevent the occurrence of pressing defects by isostatic pressing machine, and the density is more uniform for cemented carbide plate blanks.

* Tungsten carbide plates come in various grades and compositions, allowing for customization based on specific

application requirements. Different grain sizes and binder compositions can be tailored to achieve the desired balance of

hardness, toughness, and wear resistance. ss.

Grade

|

Grade

|

Density (g/cm3)

|

Hardnes HRA

|

T.R.S Mpa

|

Performance & application recommended

|

|

YG6A

|

14.85

|

92.5

|

2000

|

Fine grain alloy,good wear resistance.it is suitable for manufacturing forming cutter,wear-resistant parts etc.

|

|

YG8

|

14.7

|

89.8

|

2800

|

High bending strength,wear resistance lower than YG6A, suitable for manufacturing cutter ,wear-resistant parts etc.

|

|

YG11

|

14.4

|

88.5

|

2900

|

High bending strength,wear resistance lower than YG6A, suitable for manufacturing cutter ,wear-resistant parts etc.

|

|

YG15

|

14.0

|

87.0

|

3000

|

Suitable for manufacturing punching dies, wear-resistant parts.

|

|

YG20

|

13.5

|

85.5

|

2800

|

High bending strength,suitable for manufacturing progressive dies and other punching dies.

|

|

YG25

|

13.1

|

81.5

|

2950

|

High bending strength,wear resistance lower than YM6A, suitable for manufacturing cutter ,wear-resistant parts etc.

|

|

YS2T

|

14.25

|

92.0

|

2500

|

Fine grain alloy, with high wear resistance, bending strength, bonding resistance and thermal strength. it is suitable for

machining refractory alloys,stainless steel, high manganese steel, etc. |

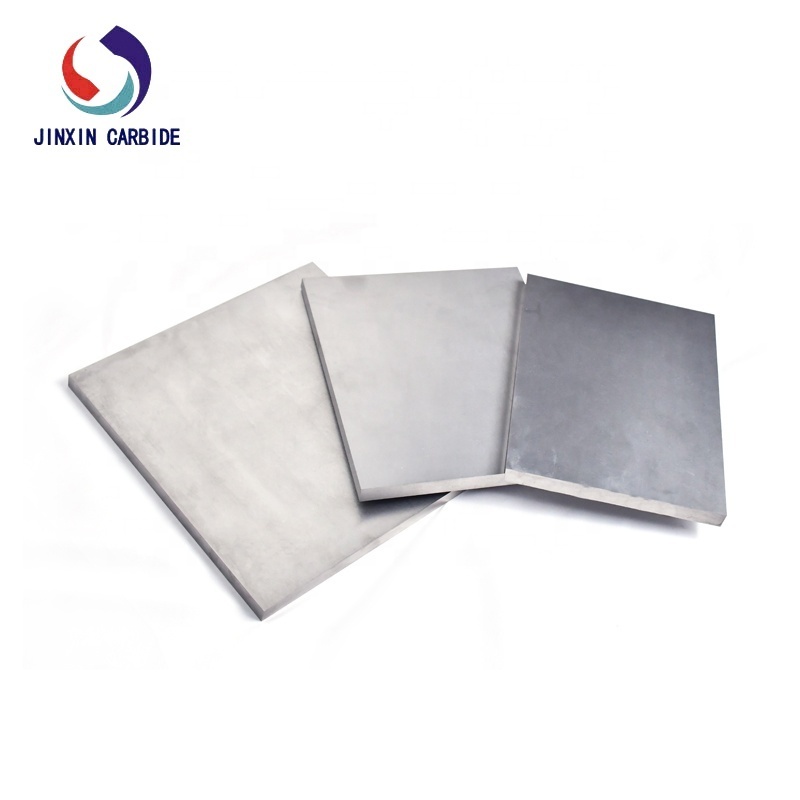

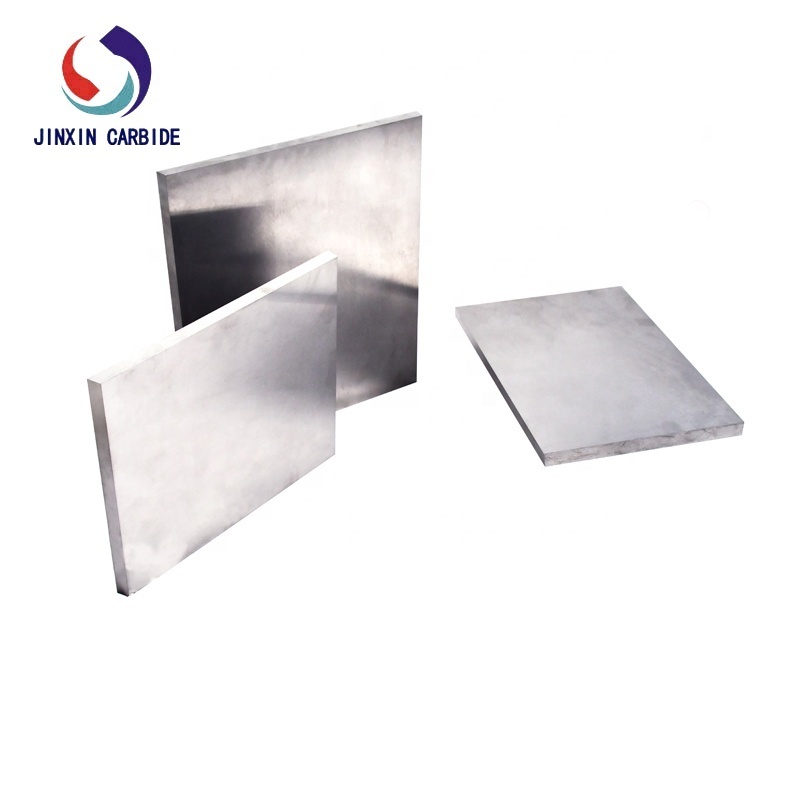

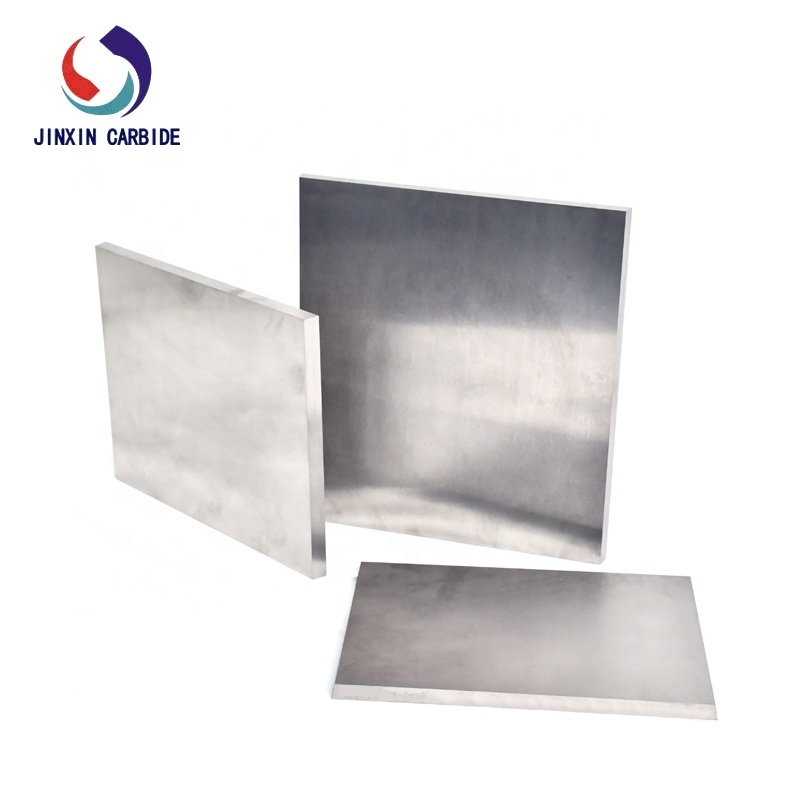

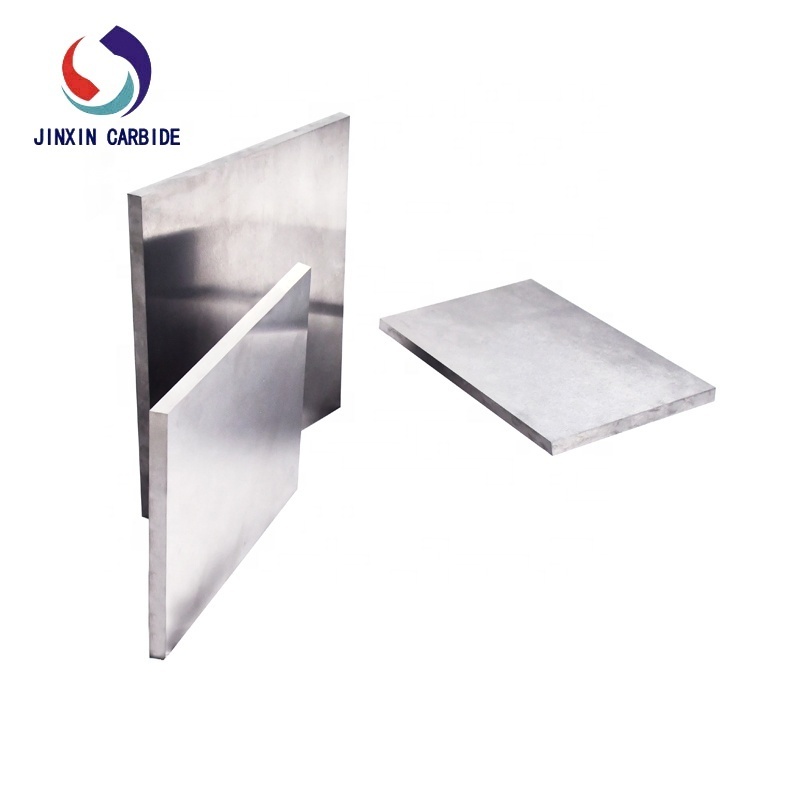

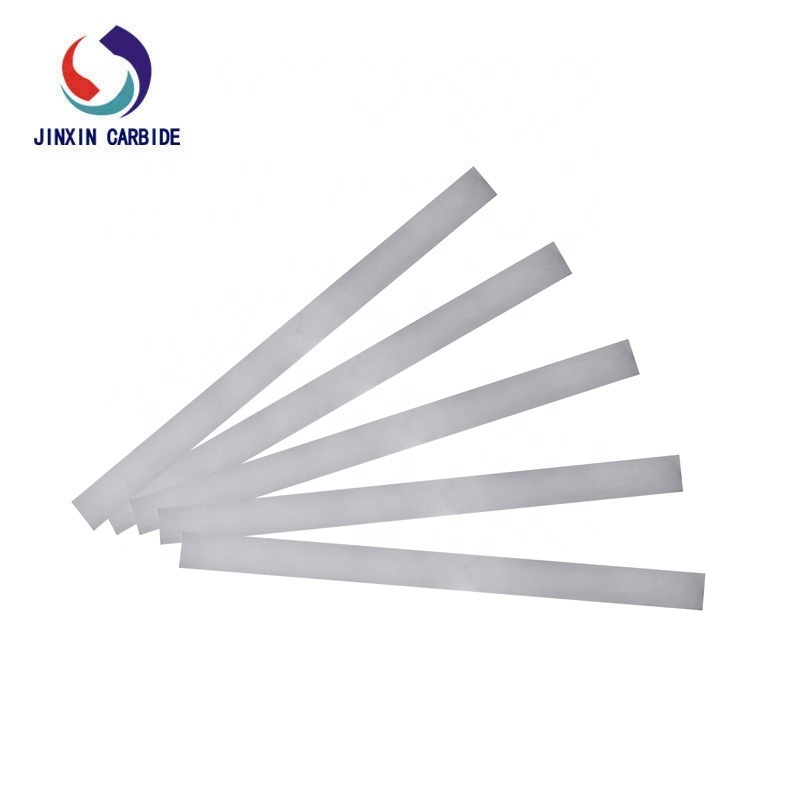

Product Show

Recommended SIZES

|

Type (L×W )

|

Thickness (H)

|

Length tolerance (L)

|

Width tolerance (W)

|

Height tolerance(H)

|

|

50×50

|

1.5~10

|

L×±1.5%

|

W×±2.5%

|

H×±2.5%

|

|

100*100

|

2.5~60

|

L×±1.5%

|

W×±2.5%

|

H×±2.5%

|

|

120×120×

|

2.5~60

|

L×±1.5%

|

W×±2.5%

|

H×±2.5%

|

|

150×150×

|

2.5~60

|

L×±1.5%

|

W×±2.5%

|

H×±2.5%

|

|

200×200×

|

2.5~60

|

L×±1.5%

|

W×±2.5%

|

H×±2.5%

|

|

300×200×

|

2.5~60

|

L×±1.5%

|

W×±2.5%

|

H×±2.5%

|

Main Process flow

Powder milling→ formula according to application requirements → wet milling → mixing → crushing → drying → sieving → adding forming agent → redrying → sieving to obtain cemented carbide powder→ granulating → pressing → forming → low-pressure sintering→blanks→Flaw inspection→Packing→Warehousing

Powder milling→ formula according to application requirements → wet milling → mixing → crushing → drying → sieving → adding forming agent → redrying → sieving to obtain cemented carbide powder→ granulating → pressing → forming → low-pressure sintering→blanks→Flaw inspection→Packing→Warehousing

More Products

Hot Searches