- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Ailin

-

Voltage:

-

380V/220V/110V, customized

-

Dimension(L*W*H):

-

Customized Design

-

Weight (KG):

-

1000

-

Frequency:

-

50HZ/60HZ

-

Heating method:

-

Electric/Gas/Diesel/LPG

-

After-sales Service:

-

Engineers available to service overseas

-

Curing Temperature:

-

180-250°C, adjustable

Quick Details

-

Machine Type:

-

Manual powder coating line, Spray Booths, Spray Booths, Painting Equipment, Pre-treatment Equipment, Conveying Equipment, Coating Equipment, Other

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Ailin

-

Voltage:

-

380V/220V/110V, customized

-

Dimension(L*W*H):

-

Customized Design

-

Weight (KG):

-

1000

-

Frequency:

-

50HZ/60HZ

-

Heating method:

-

Electric/Gas/Diesel/LPG

-

After-sales Service:

-

Engineers available to service overseas

-

Curing Temperature:

-

180-250°C, adjustable

PRODUCT DESCRIPTION

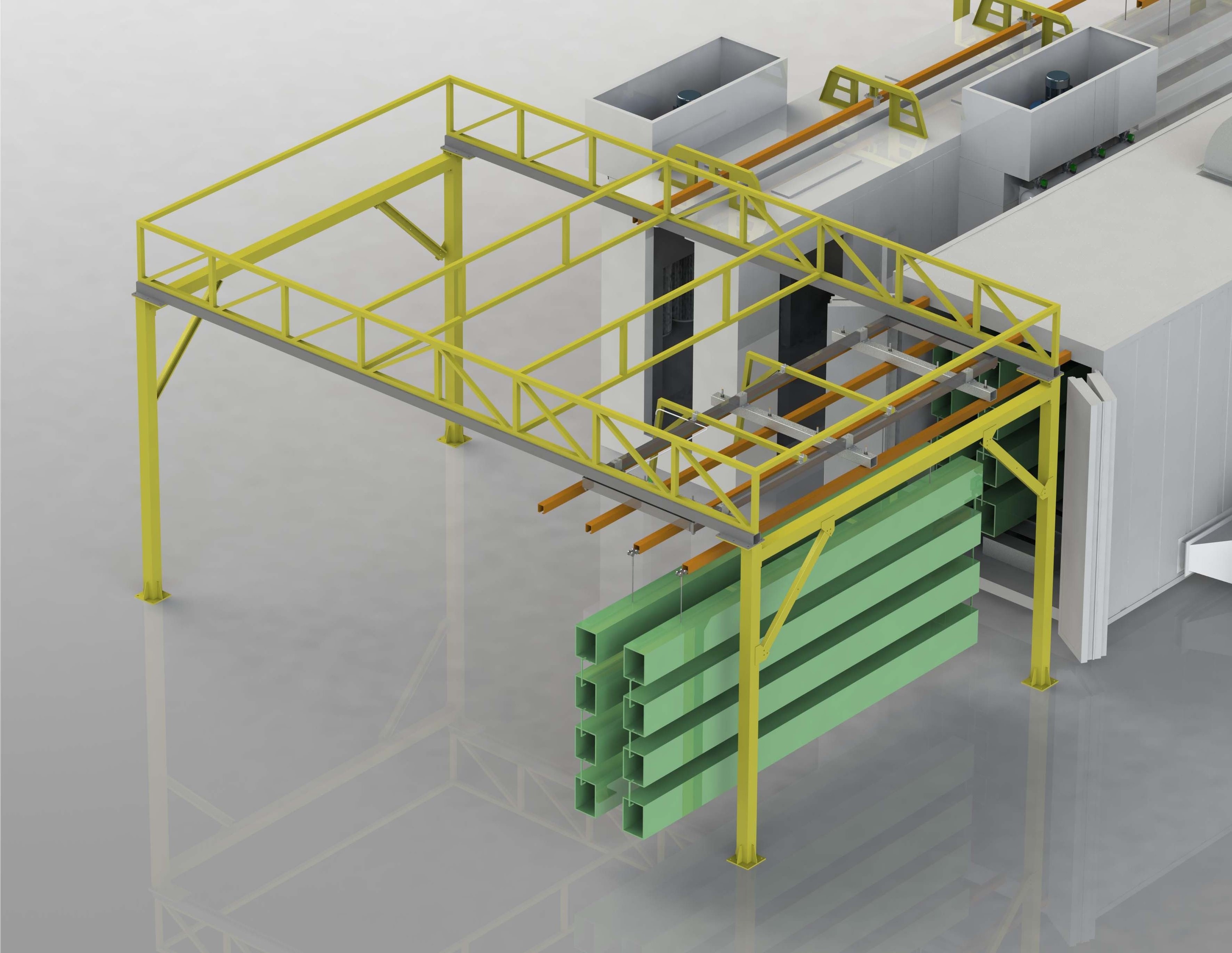

Ailin Manual Electrostatic Powder Coating Line With Overhead Conveyor

▶

Enhance the appearance quality of products.

▶

Improve worker's operating environment thoroughly.

▶

Reduces worker's labor intensity and energy consumption.

▶

Smoothen the physical distribution.

▶

The labor productivity will be higher.

|

SPECIFICATIONS :

|

|

|

|

Model

|

AL-M08

|

|

|

Main Material

|

Steel Plate

|

|

|

Worksize Dimensions (D×W×H)

|

Customized

|

|

|

Voltage/Frequency

|

415V/380V/220V/110V (50-60Hz)

|

|

|

Heating Method

|

Electric/Gas/Diesel/LPG

|

|

|

Work Temperature

|

180°C-250°C (< ± 3-5°C), Warm-up in 15-30min

|

|

|

Type of conveyor

|

Manual

|

|

|

Work Shop

|

According to the order

|

|

|

We could customize the design and any size for powder coating line.

|

|

|

CASE STORIES

Ailin I

ntelligent

specializes in optimizing various types of project in the business of industrial surface treatment lines. We have a great deal of experience in coating line system for nearly 13+ years, and provide technical support as well as installation guide to customers. The pictures above show the cases of practical application in workshops FYI.

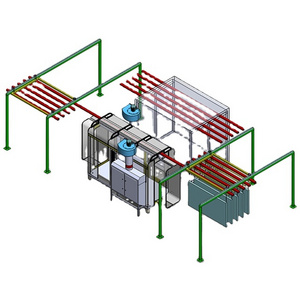

SCHEMATIC DRAWING

COMPLETE PROCESS:

product loading → powder coating → curing in oven → cooling → product unloading

COMPONENT DETAILS

Our powder coating line system includes:

Top conveyor system, Powder coating booth, Powder filter recovery system, Powder coating oven.

1. Powder Spray Booth System:

Engineered with dual working station that supports to coat both sides simultaneously.

Top track of powder coating booth could be connected to the powder coating line conveyor to achieve continuous production, increases powder coating efficiency and ensures application quality.

<

ADVANTAGES

>

•

Compact Modular design for most types of Spraying Application.

• Manual powder coating system is especially suitable for large workpieces that are difficult to spray.

• Maximum utilization of powder, 98% high levels of powder recovery.

• Complies with current health and safety legislation.

2.

Overhead Conveying Transport System:

Type: QXG 250 transport chains, the single guide wheel double walking wheel structure is adopted to promote the chain to run more smoothly. The whole line chain guide column adopts 100 mm square tube column, and the guide rail adopts "C" type steels.

Match 2 pcs of push shelves.

<

ADVANTAGES

>

• Labour-saving.

• Move smoothly.

• Stable metal support frame.

• Easy to assemble and disassemble.

3. Powder Coating Curing Oven (Gas/Electric/Diesel/LPG):

Engineered with top tracks to connect to powder coating line conveyor system, track could be customized.

Sandwich structured oven wall: 100 mm thick rock wool board is inserted between galvanized inner wall and color-steel external skins for optimum insulation effect. Powerful Circulation Fan circles hot air in the chamber to ensure

uniform

temperature distribution.

• Temperature auto control system and digital display for temperature.

• Heating source can be customized as electric, gas, LPG or diesel.

4. JH-606 Intelligent Powder Coating Machine:

Good for fast color change; Controller has one-touch intelligent operation button good for flat parts, complicated parts and recoat parts; Pulse function which could reach a perfect coating effect; The new intelligent type, low failure rate, easy to use; It is very easy to operate for beginners, powerful for advanced users.

• Stable voltage with even and delicate powder outputting.

• Flat / Corner / Re-Coat mode, choosing easily.

• LED for automation makes powder automation data more accurate.

CUSTOMIZATION SOLUTION

How to get

an optimal solution

for the powder coating line?

Ailin coating has a professional and efficient working team. Our professional senior engineer will find the best solution for you.

You'd better offer the specifications of your workpiece and related information to us:

1. The production process (if you're new on coating, we will give you specialized suggestions of the whole work)

2. The size of your workpieces (including the max length, width, height and weight)

3. The capacity (how many pcs in 8 hours)

4. The available size of your factory (including the length, width and height)

5. The heating power (electricity, gas or diesel oil )

6. Automatic painting or manual painting pre-treatment process or not, if you do, automatic pretreatment, dipping pre-treatment or sand blasting.

7. How many colors do you need to change every day.

8. The local electricity conditions (_v/_phase/_hz)

Our powder coating system's design and production are all according to customer's requirement (capacity, size of workpiece, size of workshop).

1. The production process (if you're new on coating, we will give you specialized suggestions of the whole work)

2. The size of your workpieces (including the max length, width, height and weight)

3. The capacity (how many pcs in 8 hours)

4. The available size of your factory (including the length, width and height)

5. The heating power (electricity, gas or diesel oil )

6. Automatic painting or manual painting pre-treatment process or not, if you do, automatic pretreatment, dipping pre-treatment or sand blasting.

7. How many colors do you need to change every day.

8. The local electricity conditions (_v/_phase/_hz)

Our powder coating system's design and production are all according to customer's requirement (capacity, size of workpiece, size of workshop).

PRODUCT CATEGOTIES

ABOUT US

FAQ

Hot Searches