- Product Details

- {{item.text}}

Quick Details

-

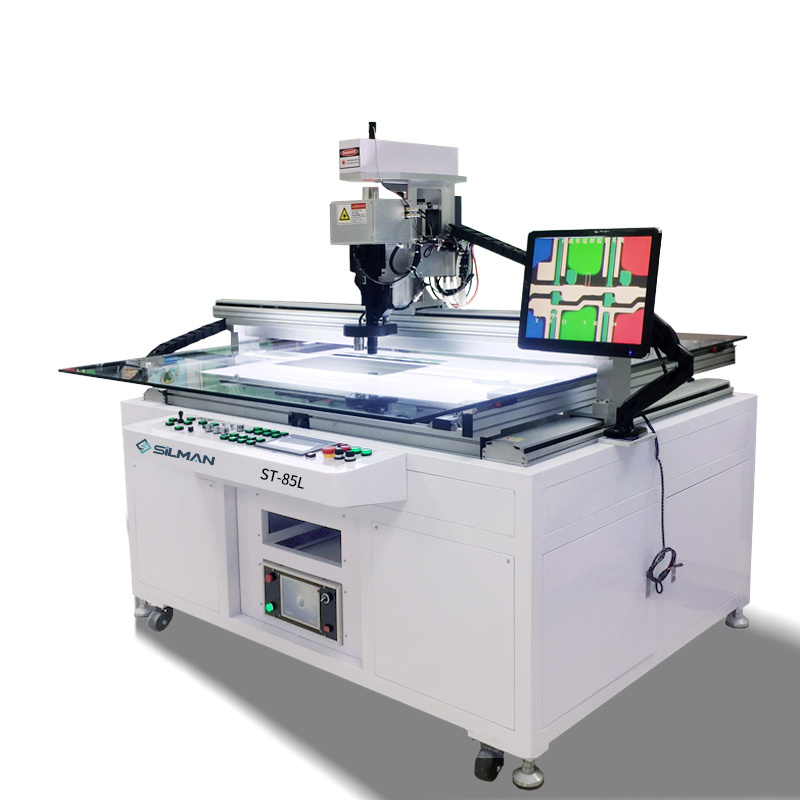

Product name:

-

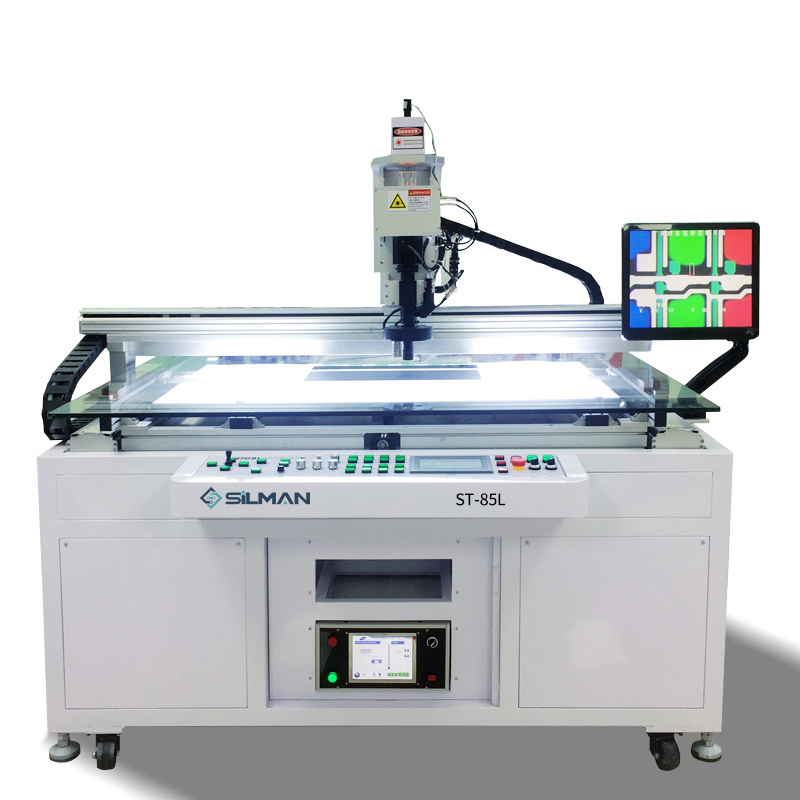

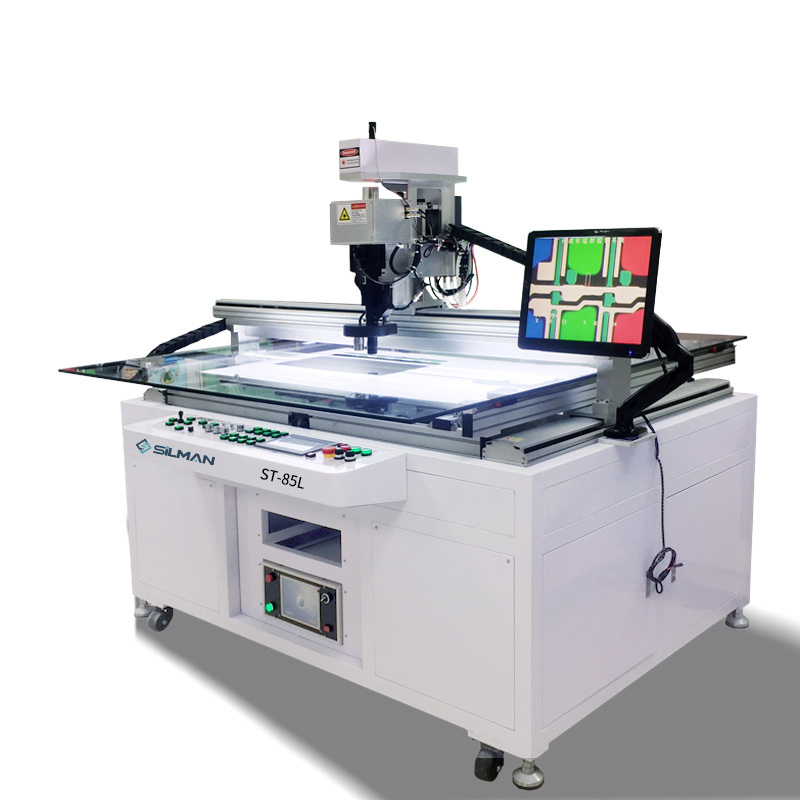

lcd tv screen laser repair machine

-

Keyword:

-

lcd laser Dotted line machine

-

Function:

-

Color Lines lcd laser repair machine

-

Name:

-

LCD line repair machine

-

Power supply::

-

220V

-

Machine weight:

-

700KG

-

Repair size:

-

12-85inch

-

Repair:

-

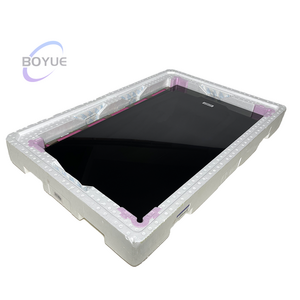

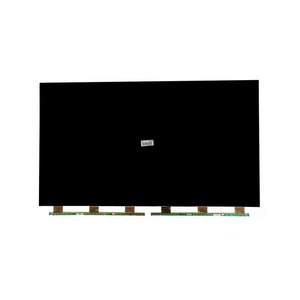

LCD, LED, TV, Laptop screen

-

Repair type:

-

Color lines and bright spot

-

cooling method:

-

Water-cooled/air-cooled

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Silman

-

Weight (KG):

-

700

-

Product name:

-

lcd tv screen laser repair machine

-

Keyword:

-

lcd laser Dotted line machine

-

Function:

-

Color Lines lcd laser repair machine

-

Name:

-

LCD line repair machine

-

Power supply::

-

220V

-

Machine weight:

-

700KG

-

Repair size:

-

12-85inch

-

Repair:

-

LCD, LED, TV, Laptop screen

-

Repair type:

-

Color lines and bright spot

-

cooling method:

-

Water-cooled/air-cooled

Product Description

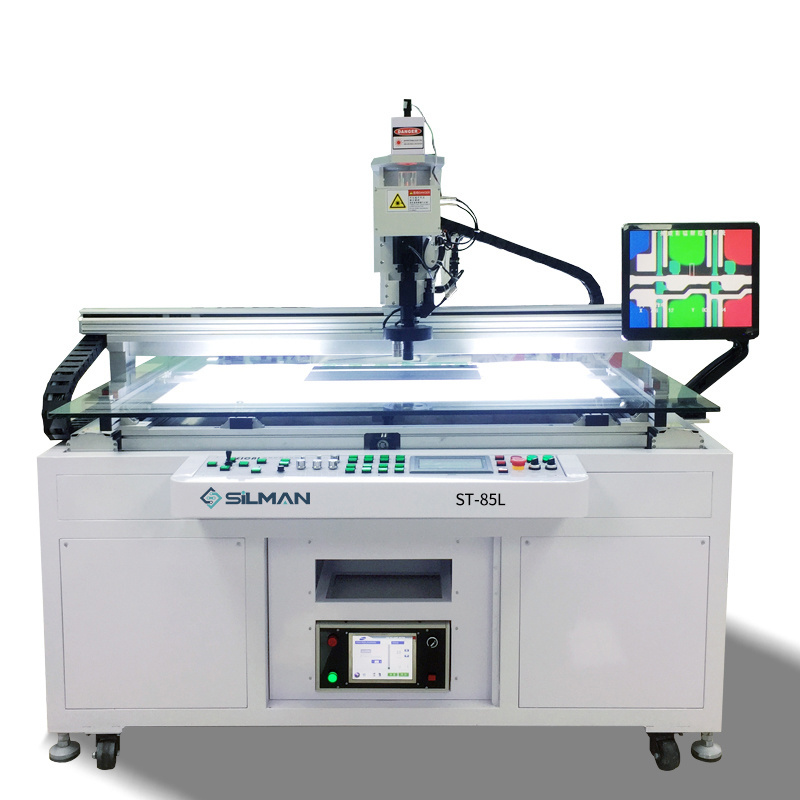

Top Quality Laser Repair Machine For Lcd Panel Open Cell TV Line Up To 85 Inch

What can a lcd laser repair machine repair?

1, Defective Color Lines (Horizontal lines and Vertical lines), White Spots, Bright Line, Half line, Multi-line, Dotted line, etc

, Caused by short circuit or impurities.

2, Support Display TFT-LCD、IPS、LTPS、OLED, etc.

3, Support LG, SAMSUNG, Toshiba, Sony, CHANGHONG,TCL,Haier,Skyworth, Hisense, Konka

and other all brand LCD Display.

4, Support MAX 100inch Size LCD;

5, Support 2k, 4K LCD.

Applicable to users:

1, Large-Scale LCD Panel Manufacturer, TV Factory;

2, After Market Service (AMS) Company, LCD Screen Maintenance Industry.

3, LCD TV Distributors to Provide After-Sales Service.

4, Brand LCD TV Company Authorized/Cooperated Service Company

How to use a lcd laser repair machine?

1, Inspection: HD Microscope Imaging to Figure Out Defective LCD area and Control Circuit(Gate Lines).

2, Repair : Use Powerful Laser to Micro Weld/Solder the Mask on Backup Lines, to Re-connect to the “Ok” Control Circuit of the

Same Color, to Re-gain the Voltage signal.

3, Test: Review the repaired LCD area

1, Defective Color Lines (Horizontal lines and Vertical lines), White Spots, Bright Line, Half line, Multi-line, Dotted line, etc

, Caused by short circuit or impurities.

2, Support Display TFT-LCD、IPS、LTPS、OLED, etc.

3, Support LG, SAMSUNG, Toshiba, Sony, CHANGHONG,TCL,Haier,Skyworth, Hisense, Konka

and other all brand LCD Display.

4, Support MAX 100inch Size LCD;

5, Support 2k, 4K LCD.

Applicable to users:

1, Large-Scale LCD Panel Manufacturer, TV Factory;

2, After Market Service (AMS) Company, LCD Screen Maintenance Industry.

3, LCD TV Distributors to Provide After-Sales Service.

4, Brand LCD TV Company Authorized/Cooperated Service Company

How to use a lcd laser repair machine?

1, Inspection: HD Microscope Imaging to Figure Out Defective LCD area and Control Circuit(Gate Lines).

2, Repair : Use Powerful Laser to Micro Weld/Solder the Mask on Backup Lines, to Re-connect to the “Ok” Control Circuit of the

Same Color, to Re-gain the Voltage signal.

3, Test: Review the repaired LCD area

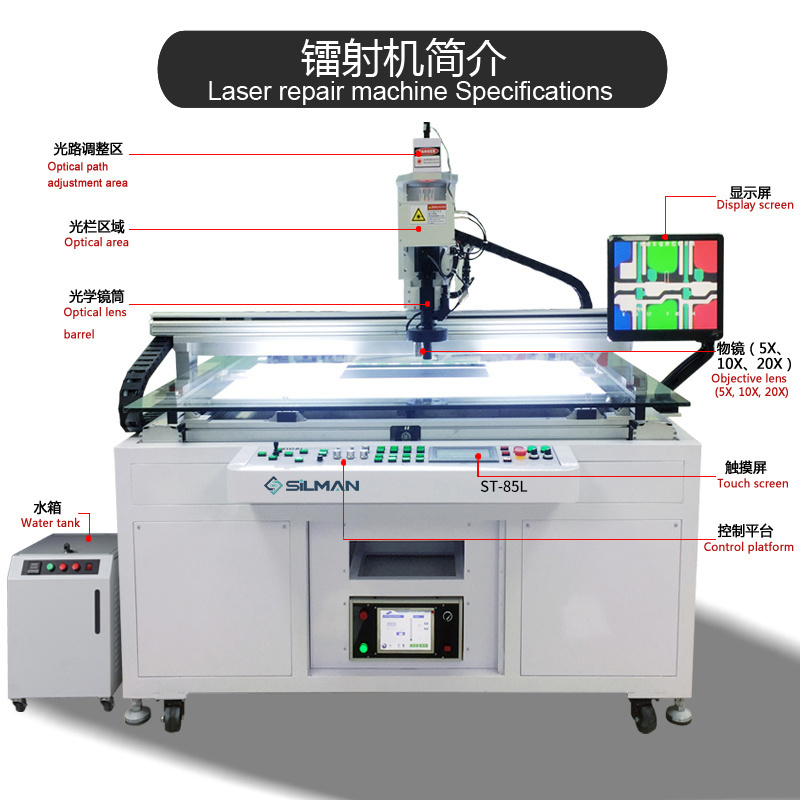

Features:

* Precise Electric Controlled Microscope, Lens Switched by One time Mouse Click.

* LASER Working Size Electric Control, with 4 different shapes optional for choice.

* Big Size Working Stage for LCD Panel.

* Inbuilt damping device to avoid images shaking.

* XYZ Axis moving speed can be adjustable and easy to be switched.

* Lens automatic switched and focus fast.

* High Resolution CCD Monitor with good quality images.

* Precise Electric Controlled Microscope, Lens Switched by One time Mouse Click.

* LASER Working Size Electric Control, with 4 different shapes optional for choice.

* Big Size Working Stage for LCD Panel.

* Inbuilt damping device to avoid images shaking.

* XYZ Axis moving speed can be adjustable and easy to be switched.

* Lens automatic switched and focus fast.

* High Resolution CCD Monitor with good quality images.

T

raining:

One device can provide 4 technicians to participate in training learning for free. combining theory with practice, let on-site technician quickly master basic operating rules of the machine, LCD panel troubleshooting methods and basic maintenance skills

.

Specification

Precision cutting of semiconductor circuits, is to repair semiconductor failures ,analysis and in optical micromachining applications excellent tools for increasing productivity .Can significantly increase the of IC design engineers and fault analysis personnel productivity ,provides valuable tools for rapid removal of passivated materials and cutting circuits .The system can greatly improve the quality of production by quickly repairing defects and re-moving short circuits.On LCD screen repair industry accounted for the high-end repair technology, the most high-end technology of LCD screen repair ,LCD screen repair industry in addition to the COF loose welding ect.(This error can be repaired with a bonding machine) others such as ITO break, short line, bright line, half-line, dotted line ,a multi-line laser machine can be used to repair. Laser machine with high efficiency, fixed rate, low cost (the same fault in the laser machine does not need replacement parts, (and do not affect the repair rate), in large-scale production factory & after sale and service company are widely used ,as the main equipment for repairing screen .

The device is using laser (good monochromatic, good coherence, good direction)&(high brightness) characteristics, under various kinds of optics effect, focused into high-energy laser,use different wavelengths(1064nm,532nm) repairing Short Circuit Defects in TFT-LCD/OLED Processes,to improve the yield rate.

|

Product name

|

LCD laser repair machine

|

|

Device parameters Dimensions:

|

2003mm × 1650mm × 1860mm(According to the actual design)

|

|

Machine weight

|

515KG

|

|

Laser system

|

water-cooled

Laser power : 0.5-2mJ/Pulse Frequency of vibration : 1 ~ 5 Hz/ second |

|

Peak power

|

1MW

|

|

Repair type

|

Color lines and bright spot

|

|

cooling method

|

Water-cooled/air-cooled

|

|

laser power

|

3-8 mj/Pulse

|

Why Choose Us

FAQ

If you have more questions about our lcd tv panel screen repair laser machine, feel free to ask.

Yes, we are a manufacturer of various lcd screen bonding machines.

2. What are the main products?

Laser lcd repair machines and cof/tab bonding machines for screen repair.

3. will you provide free spare parts?

Spare parts are free to provide under warranty if the machine goes wrong.

4. Is there free training on how to use the machine?

We provide video and factory free training to our clients if necessary.

5. Is customized service available?

YES, the size, color, logo etc can be customized.

6. What about the delivery time?

We can ship the machine in 3 days after payment if it is in stock. Please check with our sales first.

Recommend Products

Contact US

Contact: Celina

Whatsapp/Wechat: +8613823389052

Email:info@silmantech.com

Shenzhen Silman Technology Co., Ltd.

Whatsapp/Wechat: +8613823389052

Email:info@silmantech.com

Shenzhen Silman Technology Co., Ltd.

Hot Searches