Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu China

-

Brand Name:

-

MINGSHUN

-

Voltage:

-

380V50Hz3Phase, customized

-

Dimension(L*W*H):

-

30x2x2.5m

-

Power (kW):

-

75

-

Weight:

-

9000 KG

-

Processing Type:

-

Exturding Machine

-

Final product:

-

pe pipe

-

Motor brand::

-

Siemens Beide

-

Raw material:

-

PE granules

-

Contactor:

-

Siemens or Schneider

-

Temperature controller:

-

RKC or OMRON

-

Main inverter brand:

-

Siemens or ABB

-

Usage:

-

water and electrical wire pipe

-

Certification:

-

CE ISO

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

38:1

-

Screw Speed (rpm):

-

120 rpm

-

Place of Origin:

-

Jiangsu China

-

Brand Name:

-

MINGSHUN

-

Voltage:

-

380V50Hz3Phase, customized

-

Dimension(L*W*H):

-

30x2x2.5m

-

Power (kW):

-

75

-

Weight:

-

9000 KG

-

Processing Type:

-

Exturding Machine

-

Final product:

-

pe pipe

-

Motor brand::

-

Siemens Beide

-

Raw material:

-

PE granules

-

Contactor:

-

Siemens or Schneider

-

Temperature controller:

-

RKC or OMRON

-

Main inverter brand:

-

Siemens or ABB

-

Usage:

-

water and electrical wire pipe

-

Certification:

-

CE ISO

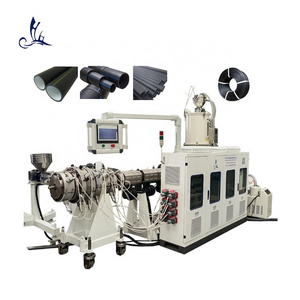

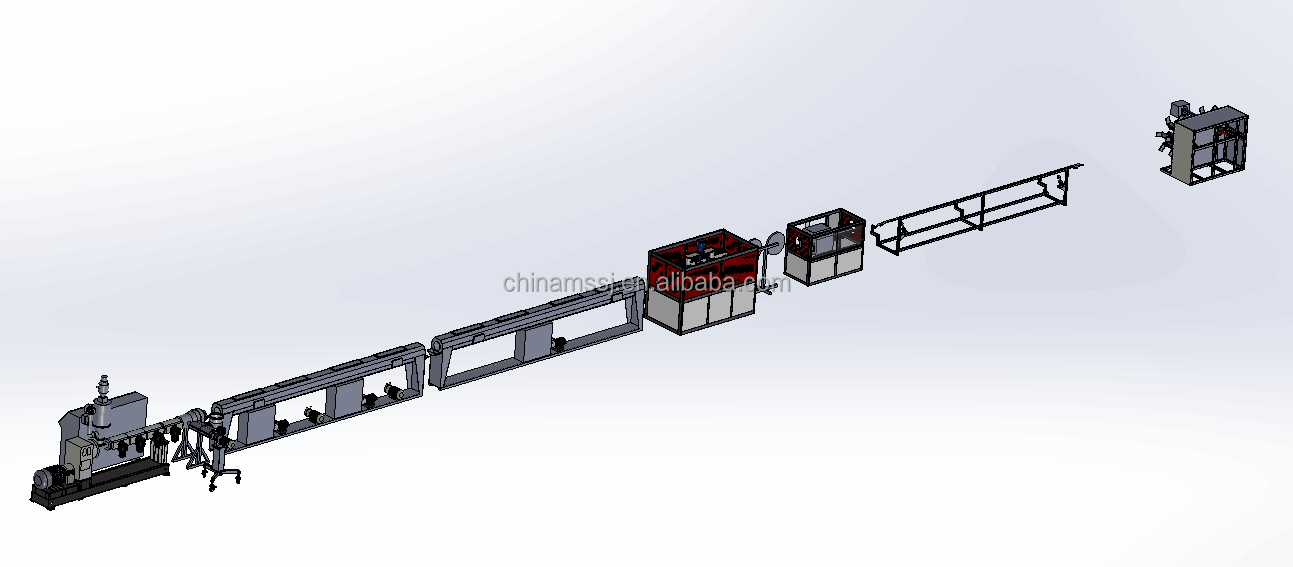

The machine consists of consists of vacuum calibration tank, haul off unit,cutting unit, stacker/winder etc.

The single screw extruder and haul off unit apply famous A/C frequency conversion speed regulation device, both vacuum pump and driving motor applies famous brand.

The haulf-off unit includes various of caw type etc.

Dust free, saw blade or planetary cutting machine can be applied, the property of machine group is reliable.

The production efficency is high with special device.

It can produce inner wall spiral pipe , inner wall hollow pipe and core layer foam pipe.

It can also produce PP,PE,ABS, PPR, PEX, Silicon core pipe etc.

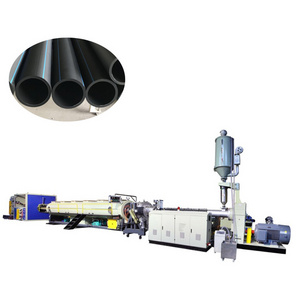

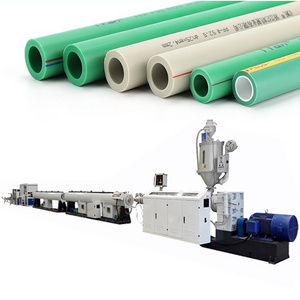

PPR/PERT pipe production line

The Line is maily used in producing pipe with PPR resin mateials also used in PB PPC PE resin pipe material production.

PLC control, high degree of automation; Adopting special and good effect screw; Adopting compound spiral head, effectively deleting memory function of material; vacuum calibration, constant temperature control,eliminating pipe stress Adopting co-extrusion head to make the tube with color line. High extrusion capacity, wide processing range of raw materials

Flow Chart

PE granules raw material &additive ---vacuum feeding machine---hopper dryer---single screw extruder---color mark line extruder---mould ---cacuum calibration cooling tank---hauling off machine---cutting machine .

| Model/item | Pipe range(mm) | Extruder | Output(kg/h) | Total Power(kw) |

| PE-63 | 16-63 | SJ65/33 | 120-180 | 45kw |

| PE-110 | 16-110 | SJ65/33 | 150 | 55kw |

| PE-160 | 50-160 | SJ75/33 | 180 | 75kw |

| PE-250 | 75-250 | SJ75/33 | 300 | 90kw |

| PE-315 | 110-315 | SJ90/33 | 250-350 | 132kw |

| PE-450 | 160-450 | SJ90/33 | 350-450 | 160kw |

| PE-630 | 315-630 | SJSZ120/33 | 550-850 | 200kw |

| PE-800 | 450-800 | SJ150 /33 | 800-1300 | 250kw |

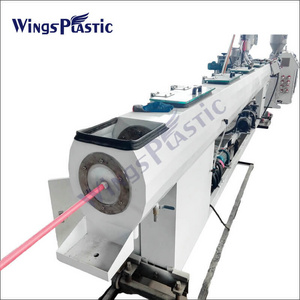

Details images

Hopper dryer

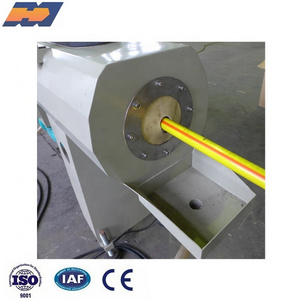

Single screw extruder machine

1) World famous brand eletrical component such as Siemens,Schneider,ABB etc.

2) High torque gearbox with adopts NSK/SKF bearing.

3) Bimentallic screw and barrel.

4) Intelligent PLC controlling system with human-friendly interface.

mould

1) Material of mould body is 45# steel harden treated and polished.

2) Material of inner mould part is 40Cr.

3) The material of calibration bushing is stannum broze.

4) The diameter can be customized.

vacuum calibration and cooling tank

1) The function is calibrate the outer diameters and cooling pipe primarily.

2) Material of water tank is stainless steel 304.

3) cooling model is spray-pouring cooling.

Hauling off machine

1) Function:Hauling off PE pipe stably and synchronal with extruder speed.

2) Clamping mode is pneumatically.

3) Speed adjusting mode is frequencyconversion .

Cutting machine

1) Function: Cut PE pipe in fixed length.

2) Cutting type: automatic meter counting cutter.

3) Cutting control: PLC system.

4) Material of cutting saw: alloy steel.

Winder machine