- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

0-30mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JiNan GoodCut

-

Weight (KG):

-

3000 KG

-

Product name:

-

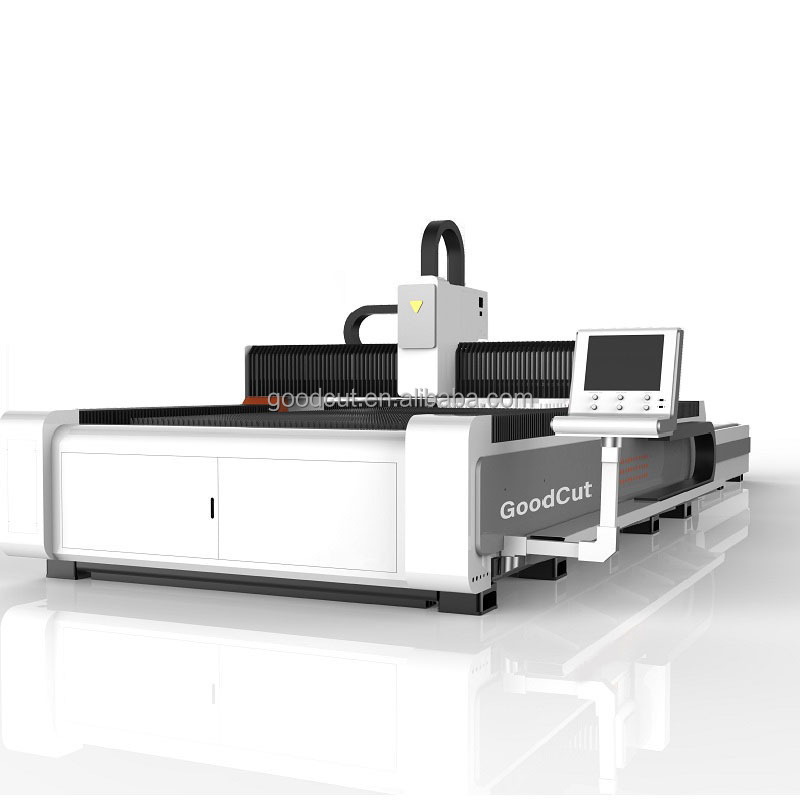

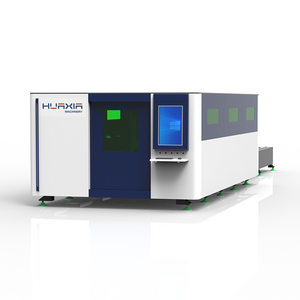

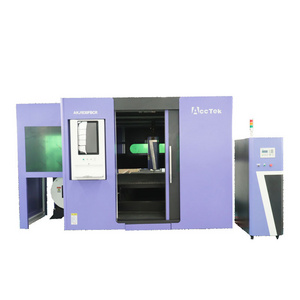

2000W 4000W Cheaper Fiber Laser Cutting Machine with Exchange Table

-

Laser source:

-

Raycus IPG MAX

-

Laser power:

-

1000W / 2000W / 3000W/4000W

-

Type:

-

Fiber Laser Cutting

-

Working area:

-

1500mmX3000mm

-

Cutting materials:

-

Stainless Steel Carbon Steel Etc( Metal Laser Cutting Machine )

-

Control system:

-

Cypcut Control System

-

Motor driver:

-

Taiwan Delta/Yaskawa servo motors and drives

-

Transmission:

-

HIWIN Guide Rails

-

Optional:

-

Automatic Exchange Table/Whole protective cover

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

100m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

0-30mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JiNan GoodCut

-

Weight (KG):

-

3000 KG

-

Product name:

-

2000W 4000W Cheaper Fiber Laser Cutting Machine with Exchange Table

-

Laser source:

-

Raycus IPG MAX

-

Laser power:

-

1000W / 2000W / 3000W/4000W

-

Type:

-

Fiber Laser Cutting

-

Working area:

-

1500mmX3000mm

-

Cutting materials:

-

Stainless Steel Carbon Steel Etc( Metal Laser Cutting Machine )

-

Control system:

-

Cypcut Control System

-

Motor driver:

-

Taiwan Delta/Yaskawa servo motors and drives

-

Transmission:

-

HIWIN Guide Rails

-

Optional:

-

Automatic Exchange Table/Whole protective cover

2000W 4000W Cheaper Fiber Laser Cutting Machine with Exchange Table for Steel

1.Feature:

1. Machine is with heavy duty frame, and also can offer OEM service.

2.Gantry double-drive structure,with imported Germany rack & gear transmission system, which improves the production efficiency.

3 High-performance cast aluminium guide rail, after infinite aalysis ,which accelerates the cicular arc cutting speed.

4.Open worktable, easy operation and small space occupation.

5. High precision, fast speed, narrow slit, minimum heat affected zone, smooth cut surface and no burr.

6. The laser cutting head does not come into contact with the surface of the material and does not scratch the workpiece.

7. The slit is the narrowest, the heat affected zone is the smallest, the local deformation of the workpiece is very small, and there is no mechanical deformation.

8.It has good processing flexibility, can process any pattern, and can cut pipes and other profiles.

9. Non-deformable cutting can be performed on materials of any hardness such as steel plates, stainless steel, aluminum alloy plates, and hard alloys.

2.Parameter:

|

1 |

Machine Name |

2000W 4000W Cheaper Fiber Laser Cutting Machine with Exchange Table for Steel |

|

2 |

Model |

GC-1530F |

|

3 |

Laser machine cutting area |

3000x1500mm (Other size can be customized,such as 4500x1500/6000x1500/6000x2000mm) |

|

4 |

Fiber Laser Power |

500w/750w/1000/1500/2200/3300/4000/ 6000/8000/12000/25000W (More suitable for >=1500W) |

|

5 |

Laser wave length |

1064nm |

|

6 |

Transmission system |

Gear + rails (we have standard brand,we can also produce as your requirements) |

|

7 |

X.Y axis location accuracy |

±0.01mm |

|

8 |

X.Y axis repeat location accuracy |

±0.01mm |

|

9 |

X.Y axis max moving speed |

30m/min |

|

10 |

Max cutting speed |

1--30m/min(it will according to metal material and laser power and machine configuration) |

|

11 |

Cutting thickness |

Detailed in the following cutting thickness |

|

12 |

Application Material |

Metal sheet Iron/CS/SS/Aluminum/Copper and all kinds metal |

|

13 |

Advantages |

>Excellent beam quality

|

|

14 |

Gross weight |

7000KG |

|

15 |

Net weight |

6750KG |

|

16 |

Machine size |

Exchange table Machine size: 5200*3000*2400mm Water chiller +Controller: 1830*920*2110mm |

|

17 |

Transport |

Shell frame for Exchange table Machine 20 Container for Water chiller +Controller |

3.Advantage:

1. Design screen, has a vertical screen display, different from the traditional horizontal screen display with good response speed, higher contrast, wider view, low power consumption as well as high resolution.

2.Germany Atlanta/Taiwan APEX Double Gear and Rack fiber laser cutting machine transmission system,

high cutting efficiency.

3.Auto clap,fast speed,save strength,no harm to working piece.

4.Ttube laser cutting machine adopts 3rd generation aluminium gantry.It is manufactured with aerospace standards

and formed by 4300 tons press extrusion molding.

5. High Cutting Speed: cutting speed is 2-3 times than same power CO2 laser cutting machine.

6. Stable Running: adopt top world import fiber lasers, stable performance, key parts can reach 100,000 hours;

7. High Efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine

have three times photoelectric conversion efficiency.

8. Low Cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%.

Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine.

4. Main Parts

(1) Raycus laser source: 1000w, 1500w, 2000w, 2500w, 3000w, 4000w, 5000w etc for optional

Germany IPG laser source for optional

(2) Raytools laser head:

Doubl-layer protection design greatly enhances the user's experience in replacing protective lenses. The risk of contamination of the lenses is almost zero.

WSX/AU3TECH for optional

(3) Cypcut control system

(4) Exchange Machine frames:

Fiber cutting head (Metal Material):

Mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting and so on.

Fiber cutting head (Metal Industries):

Applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

Samples

Jinan GoodCut CNC Machinery Co., Ltd.

The meaning of “GoodCut” brand: Good Quality, Good Price, Good Service

Good Quality

1. 15 engineers with more than 10 years rich working experience, manufacture high precision machines;

2. Three-day 72-hour testing machine inspection, after confirming that the machine has no quality problems, then it will be shipped;

3. 4 QC staffs do strict evaluations on in-coming inspections, in-process inspections and final inspections.

Good Price

1. GoodCut manufactures about 500 sets of machines per month, with a large sales volume. We have long-term cooperation with parts suppliers, can get advantageous prices of parts, so that the price of machine is very competitive;

2. GoodCut aims to develop long-term cooperation with new and regular customers, and to give customers the best prices with the most sincere attitude.

Good Service

1. English manual and video for machine using and maintaining, explaining the operation steps in detail;

2. Professional after-sales service staffs, providing 24-hour online service;

3. Provide free technical training and factory field operation teaching to eliminate customer worries.