- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

9763*900*1900mm

-

Power (kW):

-

27.5

-

Weight (KG):

-

3100 kg

-

Panel Feed Speed(m/min):

-

20m/min

-

Usage:

-

PVC edge banding machine

-

Min. narrow short side:

-

45*200mm

-

Min. narrow long side:

-

40*300mm

-

Panel thickness:

-

10-60mm

-

Edge thickness:

-

0.4-3mm

-

Feed rate:

-

18-20-23m/min

-

Pre milling:

-

yes

-

Corner rounding:

-

yes

-

Belt material:

-

PVC, ABS, WOOD etc.

-

Weight:

-

3100KG

-

Power:

-

27.55kw

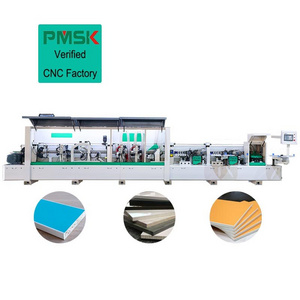

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HUAHUA

-

Voltage:

-

380V/415V/220V

-

Dimension(L*W*H):

-

9763*900*1900mm

-

Power (kW):

-

27.5

-

Weight (KG):

-

3100 kg

-

Panel Feed Speed(m/min):

-

20m/min

-

Usage:

-

PVC edge banding machine

-

Min. narrow short side:

-

45*200mm

-

Min. narrow long side:

-

40*300mm

-

Panel thickness:

-

10-60mm

-

Edge thickness:

-

0.4-3mm

-

Feed rate:

-

18-20-23m/min

-

Pre milling:

-

yes

-

Corner rounding:

-

yes

-

Belt material:

-

PVC, ABS, WOOD etc.

-

Weight:

-

3100KG

-

Power:

-

27.55kw

Products Description

10-inch touch color screen display

10-inch touch color screen display, easy to operate, save space, safe and reliable operation, simple and friendly interface, with complete operation prompts, concise and clear

Narrow panel Auxiliary Feeder

Small panel auxiliary feeding device, can seal the narrow side

Minimum size:

Minimum size:

40*300mm (when sealing the long side)

45*200mm (when sealing the narrow side)

45*200mm (when sealing the narrow side)

Large panel auxiliary wheel + narrow side support wheel

Multiple sets of auxiliary wheels can avoid too much shaking when sealing large or long boards

Narrow edge support wheels make the edge banding more accurate and the end edge banding is more stable

Narrow edge support wheels make the edge banding more accurate and the end edge banding is more stable

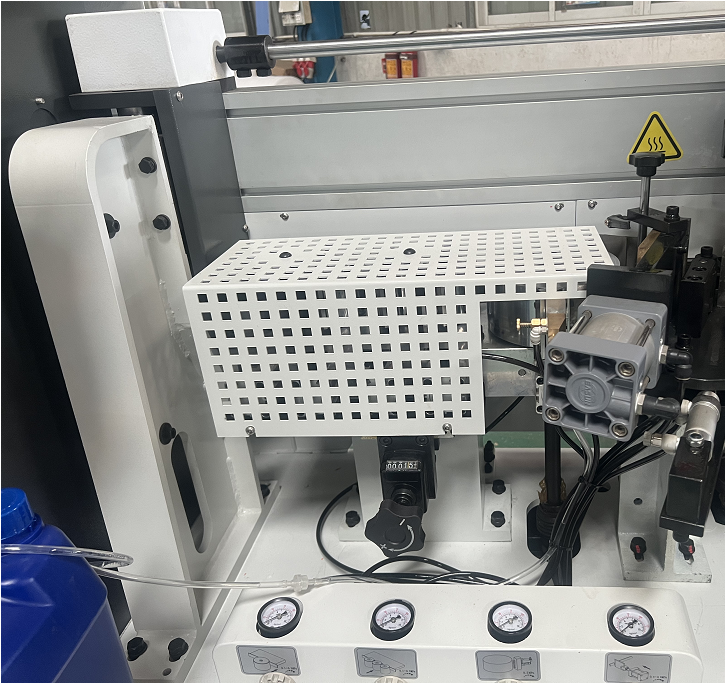

Automatic Oiling Device

According to the use time of machine working, automatically give oiling lubricating maintenance to guide rail. Ensure long-term operation stability and smooth processing,prolong the use life of the machine.

Double glue pot and Quick hot melt Device with automatic glue suction device

From the picture, you can see that there are two glue pots, one PUR glue pot (upper glue pot), one EVA glue pot (lower glue pot), and Quick hot melt Device with automatic glue suction device

The advantage of the double glue pot is that according to different colors of panels and different colors of edge banding, you can choose different colors of glue to solve the problem of glue lines

Quick hot melt Device with automatic glue suction device, It only takes 15 minutes to start working at the fastest, and there is no need to wait for the glue to melt during mass production. Avoid the trouble of manual gluing, work uninterruptedly, and avoid dry burning of the glue pot. automatic glue suction device , no need work add the glue all the time with big Glue storage tank

The advantage of the double glue pot is that according to different colors of panels and different colors of edge banding, you can choose different colors of glue to solve the problem of glue lines

Quick hot melt Device with automatic glue suction device, It only takes 15 minutes to start working at the fastest, and there is no need to wait for the glue to melt during mass production. Avoid the trouble of manual gluing, work uninterruptedly, and avoid dry burning of the glue pot. automatic glue suction device , no need work add the glue all the time with big Glue storage tank

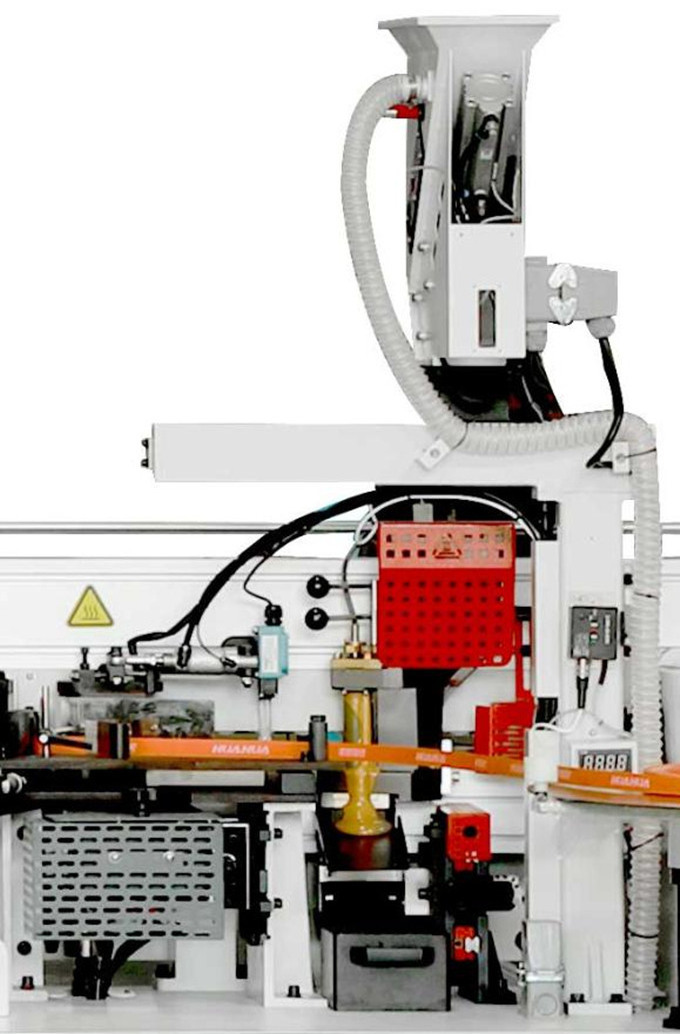

Bake Light

Bake Light -preheating, avoid degumming

After the baking lamp preheats the edge of the board, the glue is applied to seal the edge more tightly, and the edge band is pasted more firmly, which can avoid the problem of degumming caused by large temperature differences

After the baking lamp preheats the edge of the board, the glue is applied to seal the edge more tightly, and the edge band is pasted more firmly, which can avoid the problem of degumming caused by large temperature differences

Double Fine Trimming

The edge is trimmed by the double fine trimming device, which meets the automatic switching of two edge banding belts, saving time and effort, and more effectively improving the edge banding effect

End trimming unit with two high frequency motors

Corner rounding unit for soft and postforming workpieces for the processing of the ends of the panel with 0.4-3.0 mm edge material

and 10-60 mm workpiece height, With 2pcs 0.37kw motors. Suitable for straight workpiece edges.

and 10-60 mm workpiece height, With 2pcs 0.37kw motors. Suitable for straight workpiece edges.

Independent lifting of the pressure beam

The pressing unit, aligning unit and tracking unit all use independent lifting to prevent the panel from shaking and shifting,making it tighter and more stable, with precise edge banding

|

Min. narrow short side

|

45*200mm

|

Feed rate

|

18-20-23m/min

|

|

Min. narrow long side

|

40*300mm

|

Total power

|

27.5kw

|

|

Panel thickness

|

10-60mm

|

Working pressure

|

0.65mpa

|

|

Tape width

|

13-63mm

|

Size

|

9763*900*1900mm

|

|

Tape thickness

|

0.4-3.0mm

|

Weight

|

3100kg

|

Application

*

Welcome to our official website

https://www.huahuacnc.com/

Hot Searches