- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

320 mm

-

Width of Working Table (mm):

-

180 mm

-

Place of Origin:

-

China

-

Weight (KG):

-

470

-

Motor Power (kw):

-

11 kw

-

Product name:

-

Hydraulic Cnc Bending Machine

-

Application:

-

Stainless Plate Bending

-

CNC or not:

-

CNC Bender Machine

-

Material:

-

Metal Steel Sheet

-

Motor:

-

11kw

-

Weight of falling parts:

-

40kg

-

Max.hit energy:

-

0.53kj

-

Height of working area:

-

245mm

-

Hit number:

-

245mm

-

Max. square steel can be forged:

-

52x52mm

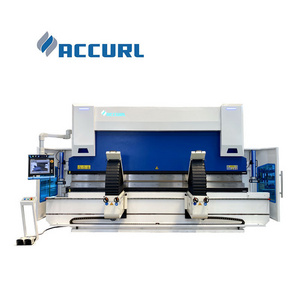

Quick Details

-

Machine Type:

-

Synchronized

-

Length of Working Table (mm):

-

2500

-

Slider Stroke (mm):

-

120 mm

-

Throat Depth (mm):

-

320 mm

-

Width of Working Table (mm):

-

180 mm

-

Place of Origin:

-

China

-

Weight (KG):

-

470

-

Motor Power (kw):

-

11 kw

-

Product name:

-

Hydraulic Cnc Bending Machine

-

Application:

-

Stainless Plate Bending

-

CNC or not:

-

CNC Bender Machine

-

Material:

-

Metal Steel Sheet

-

Motor:

-

11kw

-

Weight of falling parts:

-

40kg

-

Max.hit energy:

-

0.53kj

-

Height of working area:

-

245mm

-

Hit number:

-

245mm

-

Max. square steel can be forged:

-

52x52mm

Product Description

Specification

Product description:

1. The frame adopts whole welding structure, and by the fireplace tempering treatment, machine tool accuracy is good.

2. Hydraulic pressure type, step less pressure adjustment, using high quality imported sealing ring, to ensure the reliability of the machine tool.

3. Mechanical synchronization, using the upper and lower composite compensation structure, improve the machining accuracy of parts. (more than 160 tons for the working table compensation structure)

4. Adjust the slider stroke and adjust the position of the rear gear, use the electric quick adjustment and manual adjustment.

5. The machine tool is a little move, a single, continuous operation standard.

6. The machine tool is equipped with a safety protection bar and open door with power down device, which improves the safety of operation. (40 tons or more than 200 tons of no guard rails)

1. The frame adopts whole welding structure, and by the fireplace tempering treatment, machine tool accuracy is good.

2. Hydraulic pressure type, step less pressure adjustment, using high quality imported sealing ring, to ensure the reliability of the machine tool.

3. Mechanical synchronization, using the upper and lower composite compensation structure, improve the machining accuracy of parts. (more than 160 tons for the working table compensation structure)

4. Adjust the slider stroke and adjust the position of the rear gear, use the electric quick adjustment and manual adjustment.

5. The machine tool is a little move, a single, continuous operation standard.

6. The machine tool is equipped with a safety protection bar and open door with power down device, which improves the safety of operation. (40 tons or more than 200 tons of no guard rails)

|

Specification

|

Nominal force

|

Length of working table

|

Distance between columns

|

Throat depth

|

Max.

slide stroke |

Max.

shut height |

Travel times

|

Main motor power

|

Max.

hydraulic pressure |

|

WC67Y

|

KN

|

mm

|

mm

|

mm

|

mm

|

mm

|

mm-1

|

kw

|

mpa

|

|

30T-1600

|

300

|

1600

|

1240

|

150

|

85

|

180

|

20

|

3

|

16

|

|

30T-2000

|

300

|

2000

|

1640

|

150

|

85

|

180

|

20

|

3

|

16

|

|

40T-2500

|

400

|

2500

|

2040

|

200

|

110

|

340

|

10

|

4

|

20.5

|

|

50T-2500

|

500

|

2500

|

2040

|

200

|

110

|

340

|

10

|

4

|

20.5

|

|

63T-2500

|

630

|

2500

|

2040

|

200

|

110

|

360

|

12

|

5.5

|

20.5

|

|

63T-3200

|

630

|

3200

|

2500

|

200

|

110

|

360

|

12

|

5.5

|

20.5

|

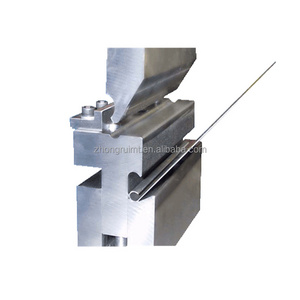

Details Images

Hot Searches