- Product Details

- {{item.text}}

Quick Details

-

Bending Precision (Deg):

-

0.01

-

Place of Origin:

-

Henan,China

-

Brand Name:

-

kellen

-

Year:

-

2024

-

Power (kW):

-

3

-

Weight (KG):

-

2500

-

Product name:

-

Stainless Steel Pipe Bending Machine

-

Application:

-

Pipes Processing

-

Raw Material:

-

Round Pipe Square Tube

-

Keyword:

-

China Pipe Bending Machine

-

Usage:

-

Pipe Tube Bending

-

Function:

-

Bending Alimunum Steel

-

Type:

-

Metal Bender Tools

-

Voltage:

-

380V

-

Certification:

-

ISO CE

Quick Details

-

Machine Type:

-

Tube Bending Machine

-

Bending Radius (mm):

-

11 - 80

-

Max. Bending Angle (Deg):

-

30

-

Bending Precision (Deg):

-

0.01

-

Place of Origin:

-

Henan,China

-

Brand Name:

-

kellen

-

Year:

-

2024

-

Power (kW):

-

3

-

Weight (KG):

-

2500

-

Product name:

-

Stainless Steel Pipe Bending Machine

-

Application:

-

Pipes Processing

-

Raw Material:

-

Round Pipe Square Tube

-

Keyword:

-

China Pipe Bending Machine

-

Usage:

-

Pipe Tube Bending

-

Function:

-

Bending Alimunum Steel

-

Type:

-

Metal Bender Tools

-

Voltage:

-

380V

-

Certification:

-

ISO CE

The pipe bending machine has automatic error detection and the fault will be timely displayed on the screen so

that the operator can discharge obstacles easily; all processing materials can be input by the touch screen; Each step of the bending can reset the compensation data, speed, release gap because of different material changes; Each bend of the same pipe can be programmed separately into 5 kinds of the action sequence, 10 sets of running speed so that the operator can use efficiently and reduce the pipe interference; The bending control and the corner feeding use servo motor to drive, with high bending angle precision and high efficiency; The equipment is particularly suitable for processing pipe fittings with many space angles and high precision requirements.

that the operator can discharge obstacles easily; all processing materials can be input by the touch screen; Each step of the bending can reset the compensation data, speed, release gap because of different material changes; Each bend of the same pipe can be programmed separately into 5 kinds of the action sequence, 10 sets of running speed so that the operator can use efficiently and reduce the pipe interference; The bending control and the corner feeding use servo motor to drive, with high bending angle precision and high efficiency; The equipment is particularly suitable for processing pipe fittings with many space angles and high precision requirements.

Product Paramenters

|

Axes

|

X1(X)

|

X2

|

R1(R)

|

R2

|

Z1

|

Z2

|

|

Stroke(mm)

|

750

|

750

|

150

|

150

|

/

|

/

|

|

Speed(mm/s)

|

500

|

500

|

180

|

180

|

2000

|

2000

|

|

Accuracy(mm)

|

0.02

|

0.02

|

0.05

|

0.05

|

0.05

|

0.05

|

|

Motor

|

servo motor

|

servo motor

|

servo motor

|

servo motor

|

servo motor

|

servo motor

|

|

Mechanical System

|

ball screw

|

ball screw

|

rack

|

rack

|

rack

|

rack

|

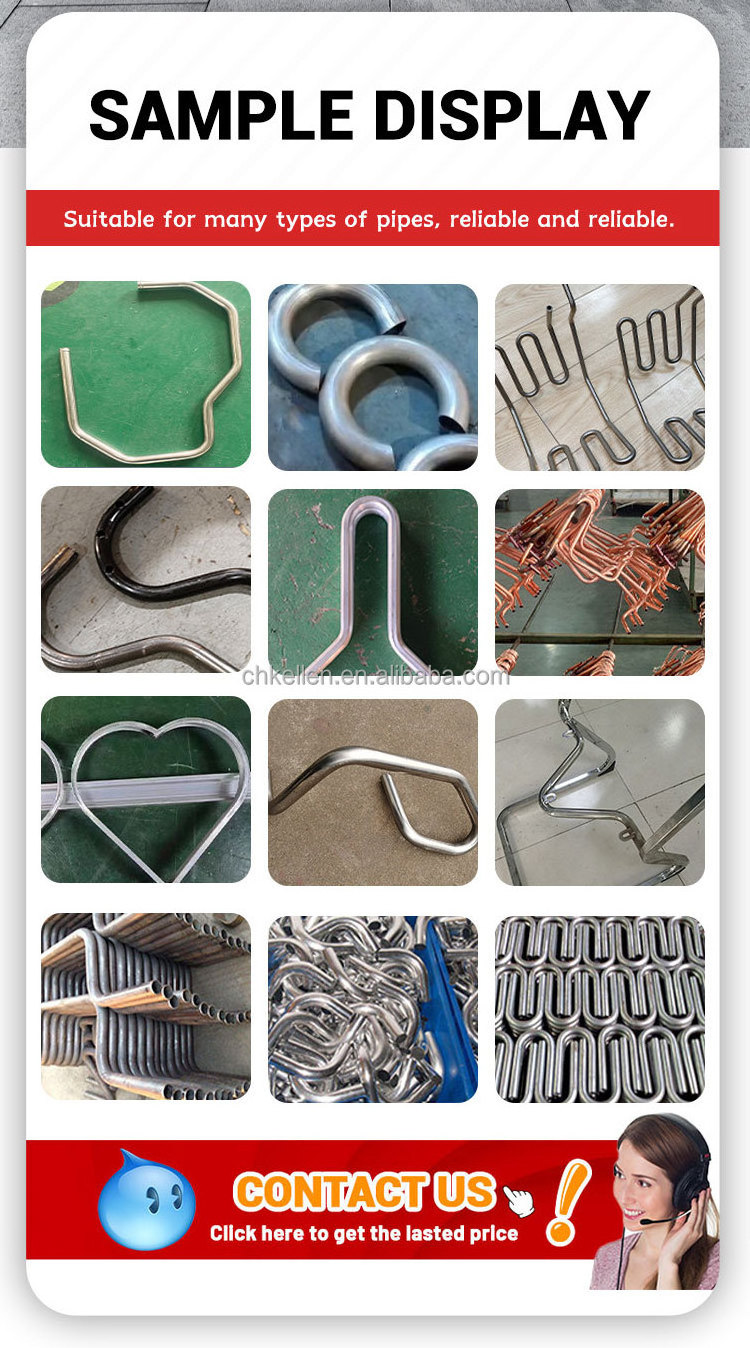

Real Product Display

Related Products

Why choose us?

♦ Project Design

Assist you to choose equipment, design production process flow According to the customer actual production environment and production requirements.

Assist you to choose equipment, design production process flow According to the customer actual production environment and production requirements.

♦ Installation Training

Provide telephone guidance for equipment installation and debugging; or send technician to install and debug machine and train your workers if needed. Provide free relevant training as customer required.

Long-term technical support.

Provide telephone guidance for equipment installation and debugging; or send technician to install and debug machine and train your workers if needed. Provide free relevant training as customer required.

Long-term technical support.

♦ After-sale service

One year warranty, life-long maintenance; 24 hours online for technical consulting service;

Once Problems on equipment, provide phone or on-site troubleshooting fault response plan.

One year warranty, life-long maintenance; 24 hours online for technical consulting service;

Once Problems on equipment, provide phone or on-site troubleshooting fault response plan.

♦ One year warranty time

From the date which the product is qualified commissioning. Any damage except the wrong operation during warranty period is repaired freely. But the travel and hotel expenses should be paid by buyer.

From the date which the product is qualified commissioning. Any damage except the wrong operation during warranty period is repaired freely. But the travel and hotel expenses should be paid by buyer.

♦ Oversea service

Engineers available to service machinery overseas.

Engineers available to service machinery overseas.

♦ Response with 24hour

We value every inquiry sent to us, ensure quick competitive offer within 24 hour.

We value every inquiry sent to us, ensure quick competitive offer within 24 hour.

♦ Full document

All necessary document will be provide .

All necessary document will be provide .

♦ Payment way

We accept multiple terms of payment, such as L/C, T/T, western Union,

Money Gram, AlibabaTade Asurance.

We accept multiple terms of payment, such as L/C, T/T, western Union,

Money Gram, AlibabaTade Asurance.

Hot Searches