- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1 kg

-

Filter Material:

-

PP String Wound Filter

-

Inner Core:

-

Polypropylene / Stainless Steel

-

Pore size:

-

1.0 um, 5.0 um, 10 um, 25 um, 50um,70 um

-

Outer Diameter:

-

63 mm

-

Inner Diameter:

-

28 mm

-

Length:

-

10, 20, 30, 40 inch

-

End Cap:

-

DOE, 222/Fin, 222/Flat, 226/Fin, 226/Flat

-

Filtration Efficiency:

-

> 80%

-

Filter Type:

-

Depth Filter

-

Application:

-

Water Treatment, Prefiltration/Clarification in Various Industries

Quick Details

-

Core Components:

-

Filter

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

TS Filter

-

Weight (KG):

-

1 kg

-

Filter Material:

-

PP String Wound Filter

-

Inner Core:

-

Polypropylene / Stainless Steel

-

Pore size:

-

1.0 um, 5.0 um, 10 um, 25 um, 50um,70 um

-

Outer Diameter:

-

63 mm

-

Inner Diameter:

-

28 mm

-

Length:

-

10, 20, 30, 40 inch

-

End Cap:

-

DOE, 222/Fin, 222/Flat, 226/Fin, 226/Flat

-

Filtration Efficiency:

-

> 80%

-

Filter Type:

-

Depth Filter

-

Application:

-

Water Treatment, Prefiltration/Clarification in Various Industries

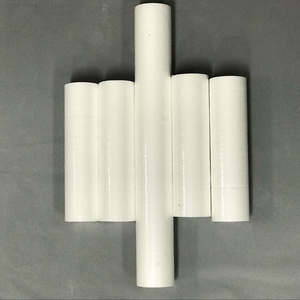

1.0 Micron PP String Wound Filter Cartridge

The string wound filter cartridges have excellent high dirt holding capacity and wide chemical compatibility, are a good choice for prefiltration/clarification and the protection of membrane filters to expand their service life. are widely used in water treatment and other processes in food&beverage, chemical and pharmaceutical industries.

- Polypropylene, bleached cotton and glass Fiber filter medias for option;

- High dirt holding capacity for depth filtration, protection of absolute filters;

- Many connections(Cut Ends, 226, 222 End caps) are available;

- Wide chemical compatiblity, pH 1-13

> Prefiltration for pure water system;

> Prefiltration for pharmaceutical and chemical solution;

> Process and waste water prefiltration in electronics industry;

> Wine,beer,mineral water,pure water,beverage filtration;

| Materials Of Construction | Filter Media: | Polypropylene/Bleached Cotton/Glass Fiber | ||||

| Micron Rating: | 1.0, 5.0, 10, 20 um | |||||

| Inner core: | Polypropylene/Stainless Steel | |||||

| O-rings/gaskets(Only for 226, 222 Ends): | Silicone, Nitrile, EPDM, Viton, etc | |||||

| Filtration Efficiency: | ≥80% | |||||

| Cartridge Dimensions | Outer Diameter: | 63mm(2.5"), 114mm(4.5") | ||||

| Inner Diameter: | 28mm(1.1") | |||||

| Length(based on Cut Ends): | 10, 20, 30, 40 Inch | |||||

| Filtration Area(m 2 ): | 0.4 m 2 per 10'' | |||||

| Operating conditions | Max.Operating Temperature.: | |||||

| Polypropylene: | 80℃ (176℉) at P≤1.0 bar (14psi) | |||||

| Bleached Cotton: | 150 ℃(300℉) at P≤1.0 bar (14psi) | |||||

| Max. Differential Pressure | ||||||

| Polypropylene: | 4.0 bar(58psi) at 25℃ (77℉) | |||||

| Bleached Cotton: | 5.0 bar(72psi) at 25℃ (77℉) | |||||

| PH Value compatibility: | 1-13 | |||||

| Sterilization: | Not recommended | |||||