- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ

-

Power:

-

11.5kw

-

Dimension(L*W*H):

-

5900*750*2100mm

-

Applicable Industries:

-

furniture workshop

-

Weight (KG):

-

1350

-

Name:

-

window frame profile wrapping machine

-

Model:

-

BXW350C

-

Color:

-

Requirements

-

Max wrapping width:

-

300mm

-

Weight:

-

1350kg

-

Total power:

-

11.5kw

-

Min wrapping length:

-

600mm

-

Wrapping speed:

-

0-25m/min

-

Application:

-

wrap wooden veneer

-

Overall dimensions:

-

5900*750*2100mm

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Marketing Type:

-

New Product 2022

-

Brand Name:

-

Hiwinstar

-

Voltage:

-

380V 50HZ

-

Power:

-

11.5kw

-

Dimension(L*W*H):

-

5900*750*2100mm

-

Applicable Industries:

-

furniture workshop

-

Weight (KG):

-

1350

-

Name:

-

window frame profile wrapping machine

-

Model:

-

BXW350C

-

Color:

-

Requirements

-

Max wrapping width:

-

300mm

-

Weight:

-

1350kg

-

Total power:

-

11.5kw

-

Min wrapping length:

-

600mm

-

Wrapping speed:

-

0-25m/min

-

Application:

-

wrap wooden veneer

-

Overall dimensions:

-

5900*750*2100mm

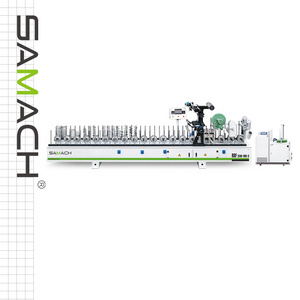

woodworking cold glue hot melt glue profile wrapping machine for pvc door/ window /wall /ceiling frames

| model no | BXW350C |

| total power | 11.5kw |

| wrapping speed | 0-25m/min |

| max wrapping width | 300mm |

| min wrapping length | 600mm |

| weight | 1350kg |

| overall dimensions | 5900*750*2100mm |

Features

Profile wrapping machine uses a PUR hot-melt polyurethane reactive glue and an automatic squeegee system. The machine has automatic dust removal, adhesive application, profile heating, automatic scraping, and protective film. The machine uses variable frequency speed regulation and worm gear transmission.

1.Finish the surface, side and bottom of the surface at one time.

2.Using touch screen, programmable controller PLC and inverter control, with convenient operation and high precision.

3.45# steel solid base, connecting parts, columns, durable, the error is less than 0.02 mm.

4.The special unit system can ensure the problems of wrinkling and unsteady pressure during the line coating process.

5.The rubber roller adopts a silicone rubber wheel, which has the characteristics of high strength, good elasticity, and difficulty in separating the metal surface.

6.The equipment is equipped with two sets of feeding shafts, which are used to alternate PVC decorative materials to improve work efficiency.

7.With precision metering pump, the feeding speed can be adjusted according to user needs.

8.Can be equipped with a substrate cleaner to automatically clean and clean the substrate into the machine.

Detailed Pictures

Application

This set of processes is widely used in some developed countries in Europe and America. It is a new direction for the development of modern building materials. The products will not be opened due to temperature changes and high temperatures. And the glue is very environmentally friendly, does not contain toxic solvents, and the interior decoration materials are more secure. Due to the anti-aging, high bonding strength, moisture resistance, irreversible and other factors of PUR glue, the finished products of this equipment can be used in various conventional harsh environments.