- Product Details

- {{item.text}}

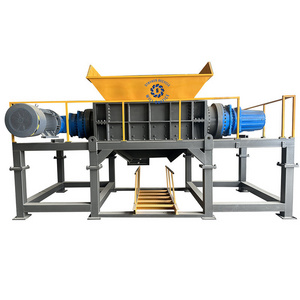

Quick Details

-

Brand Name:

-

VanSen

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

5.5

-

Weight (T):

-

4500

-

Feeding chamber size:

-

800*480mm

-

Blades material:

-

Cr12MoV/ SKD-11/H13/D2

-

Blade Cutters:

-

8-25pcs

-

Knife plate thickness:

-

15-50mm

-

Motor:

-

2 electric motors

-

Speed of Mainshaft:

-

18-20r/m

-

Crushing granularity:

-

3-10cm

-

Raw material:

-

Scrap metal, plastic,Waste tire

-

Color:

-

Can be customized

Quick Details

-

Max.Production Capacity (kg/h):

-

2500

-

Place of Origin:

-

Henan, China

-

Production Capacity (kg/h):

-

3000 - 5000 kg/h

-

Brand Name:

-

VanSen

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

5.5

-

Weight (T):

-

4500

-

Feeding chamber size:

-

800*480mm

-

Blades material:

-

Cr12MoV/ SKD-11/H13/D2

-

Blade Cutters:

-

8-25pcs

-

Knife plate thickness:

-

15-50mm

-

Motor:

-

2 electric motors

-

Speed of Mainshaft:

-

18-20r/m

-

Crushing granularity:

-

3-10cm

-

Raw material:

-

Scrap metal, plastic,Waste tire

-

Color:

-

Can be customized

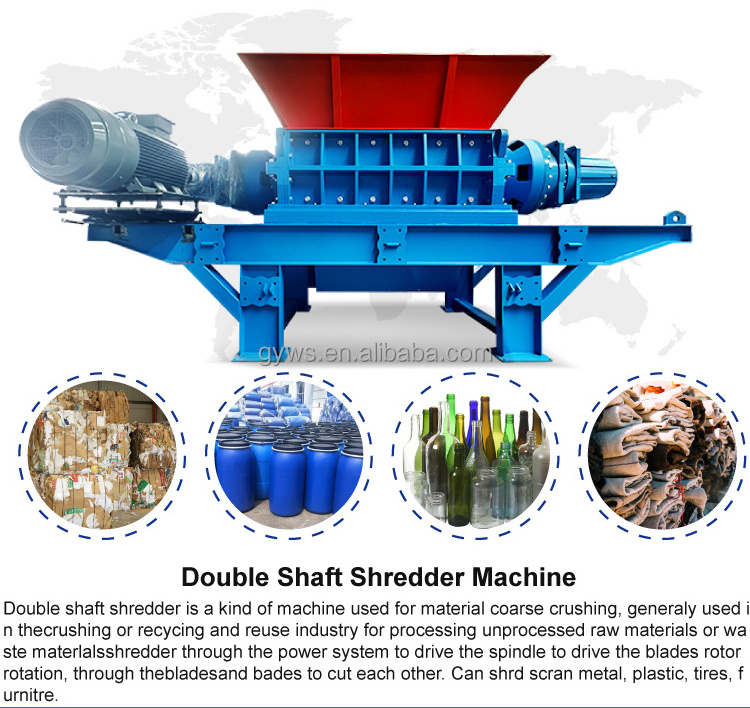

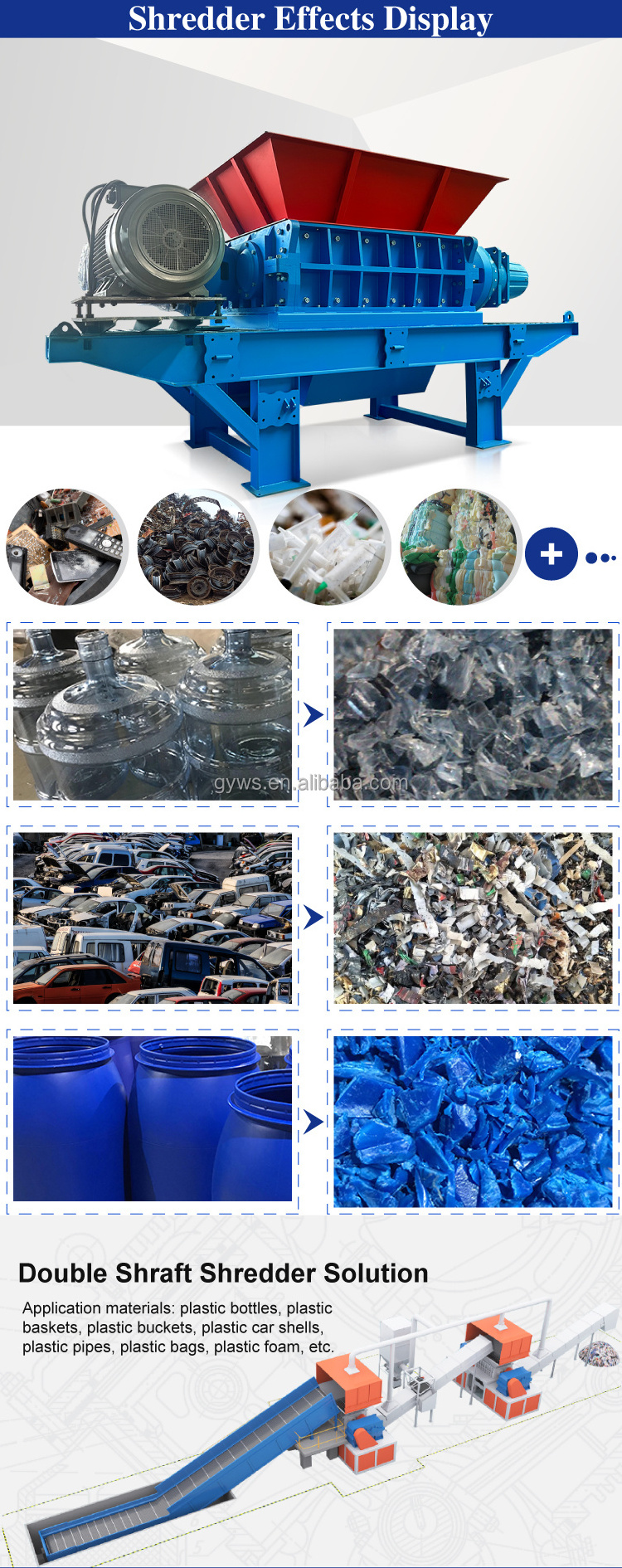

Double Shaft Shredder Machine

Double shaft shredder is a kind of machine used for material coarse crushing, generaly used in the crushing or recycing and reuse industry for processing unprocessed raw materials or waste materlals shredder through the power system to drive the spindle to drive the blades rotor rotation, through the blades and bades to cut each other, Can shrd scran metal, plastic, tires, furnitre.

|

Model

|

|

3015

|

4020

|

6025

|

8030

|

1045

|

1660

|

Customized

|

||||||

|

Power

|

KW

|

5.5/7.5

|

7.5*2

|

11*2

|

22*2

|

55*2

|

75*2

|

Customizable models according to customer needs

|

||||||

|

|

HP

|

7.5/10

|

10*2

|

15*2

|

40*2

|

75*2

|

100*2

|

|

||||||

|

Speed of Revolution

|

|

8-40

rpm

|

8-40

rpm

|

8-20

rpm

|

8-20

rpm

|

8-12

rpm

|

8-12

rpm

|

|

||||||

|

Reducer

|

|

zq250

|

zq350

|

zq400

|

zq500

|

zq850

|

zsy400

|

|

||||||

|

|

|

Different types of reducers can be selected based on the customer's feeding situation (three shaft reducers, four shaft reducers,hard tooth reducers, planetary reducers, etc.) ,which affects product prices

|

|

|

|

|

|

|

||||||

|

Blades Quantity

|

|

100mm-30

|

10mm-40

|

20mm-30

|

40mm-20

|

50mm-20

|

80mm-20

|

|

||||||

|

|

|

The thickness and quantity of blades can be customized based on the shredding material and shredding effect

|

|

|

|

|

|

|

||||||

|

Blades Diameter

|

|

150mm

|

200mm

|

250mm

|

300mm

|

450mm

|

600mm

|

|

||||||

|

|

|

The blades diameter, blade tooth shape and number of teeth of the blade can be customized based on the shredding material and shredding effect ,which affects product prices.

|

|

|

|

|

|

|

||||||

|

Blades Material

|

|

The material of the blades can be customized according to the customer's shredding materials (55sicr、5crsi、9crsi、skd11、m6v、h13) and actual usage, which affects the product price

|

|

|

|

|

|

|

||||||

|

Discharge Size

|

|

10-30mm

|

10-30mm

|

20-80mm

|

30-150mm

|

80-300mm

|

80-300mm

|

|

||||||

|

Feeding Hopper Size

|

|

0.6*0.4m

|

0.7*0.5m

|

1*0.8m

|

1.2*1m

|

1.5*1m

|

2.5x1.5m

|

|

||||||

|

|

|

The size and appearance of the feeding hopper can be customized according to the customer's feeding situation

|

|

|

|

|

|

|

||||||

|

Weight(t)

|

|

0.6

|

1.5

|

3

|

4

|

6.5

|

13

|

|

||||||

|

Capacity(t/h)

|

|

0.1-0.2

|

0.2-0.3

|

0.3-0.5

|

0.6-1

|

1-3

|

2-5

|

|

||||||

For over a decade, our company has always adhered to the business principle of "creatingvalue for customers" as the ulimate goal, market-oriented, and customer-oriented, gathering industry elites to provide customers with comprehensive solutions. At the same time. our products are exported to Japan, South Korea, China, Malaysia, Ecuador, Russia, the Philippines, Indonesia, Ghana, Vietnam and other countries and recions. Received unanimous praise in the industry with eading technology and excellent performance.

Hot Searches