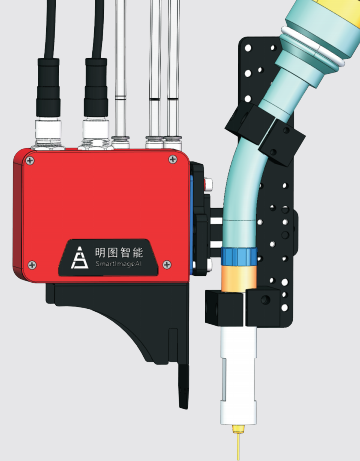

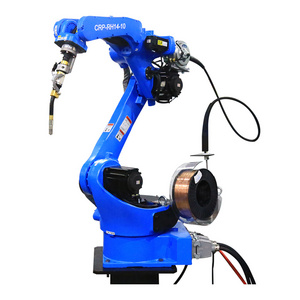

processing and welding seam identification functions are completed inside the sensor without the need for an external computer. It

has high integration and reduces the overall hardware cost of the system. Resistant to arc light and spatter, intelligently

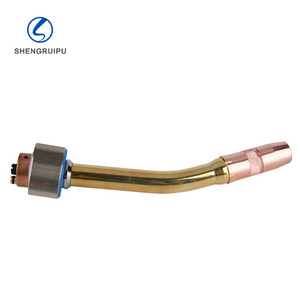

identifies weld seams, and is easy to operate. It has an exquisite structure, compact size, high accessibility, and rich types. It

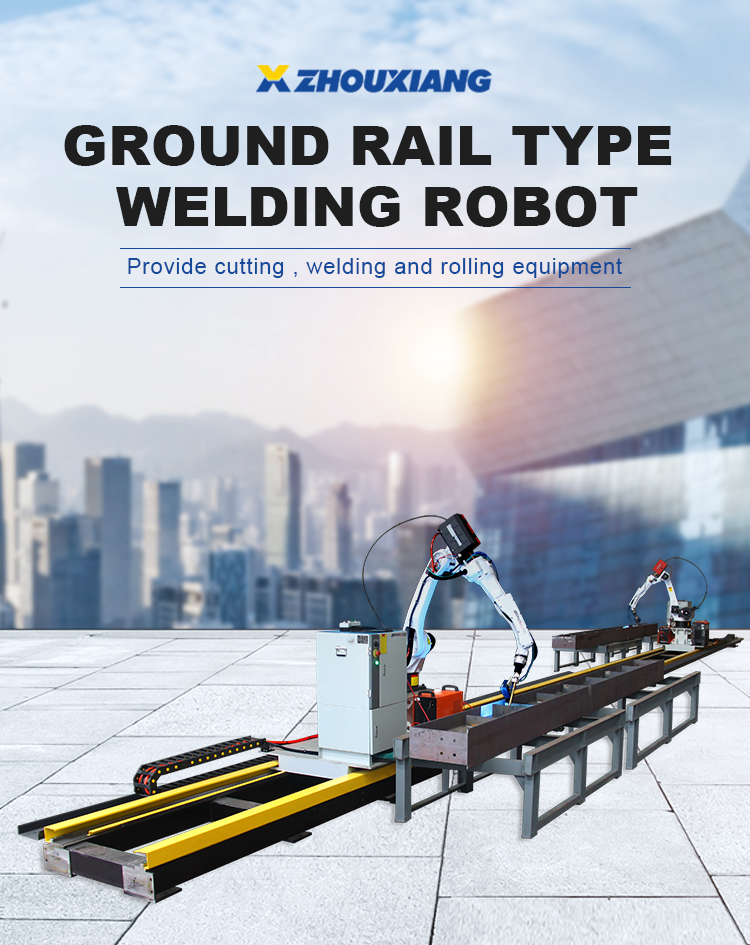

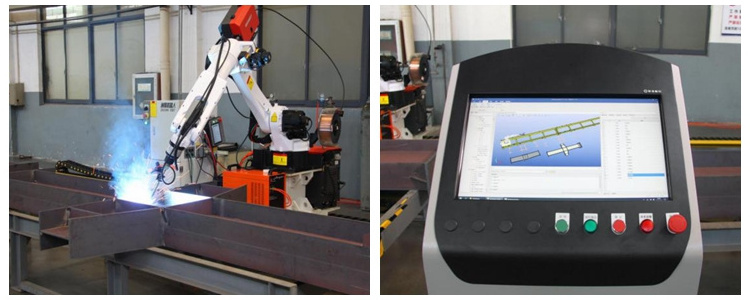

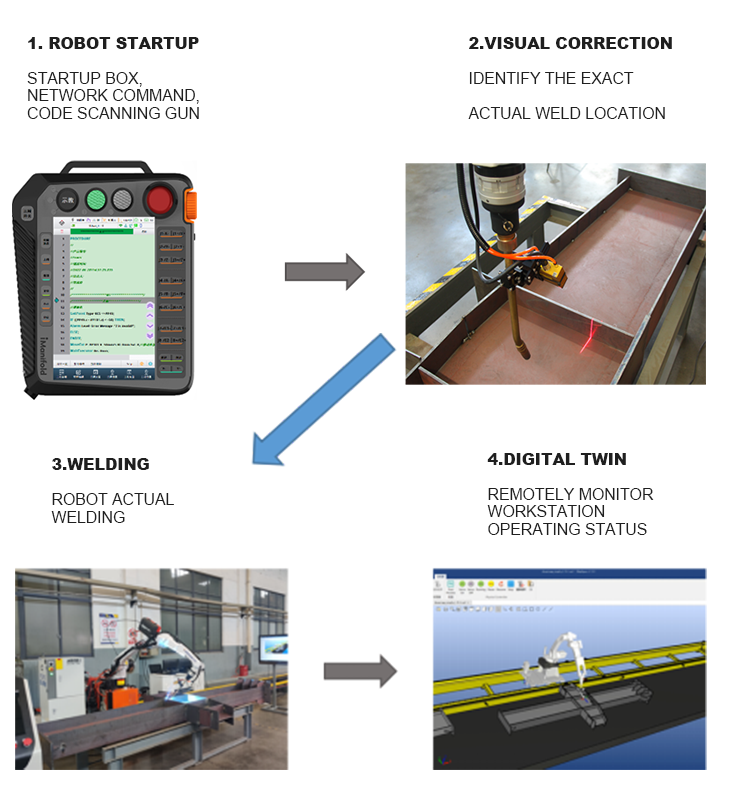

can be selected and used according to the application scenario, and the most suitable parameters can be customized. Fully Automatic Intelligent Robotic Workstation Automatic Arc Welding Robot