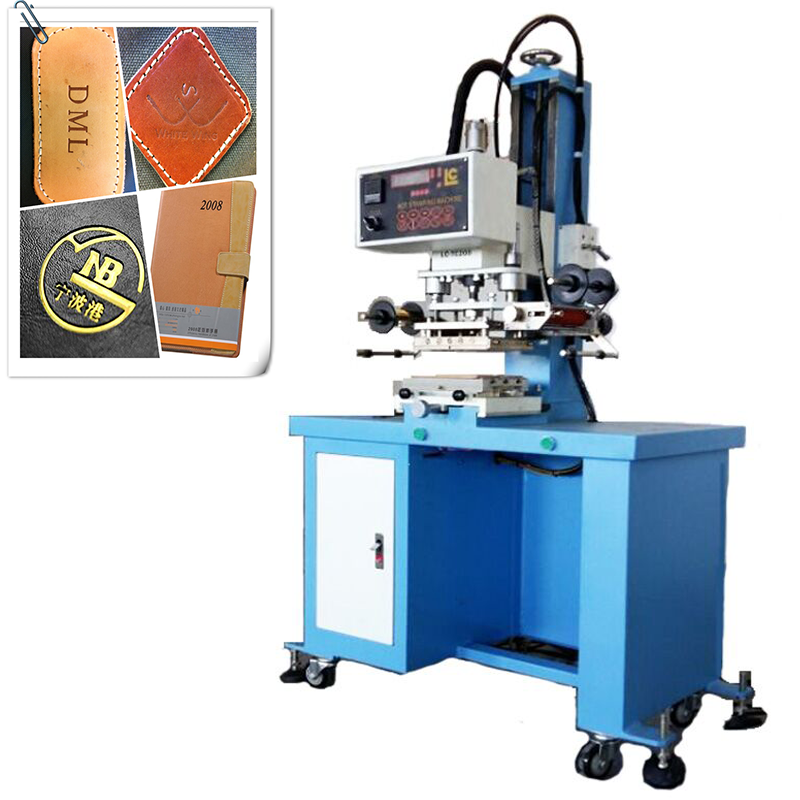

The hot stamping process is based on the principle of hot pressing transfer, so that the surface of the substrate is formed.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LC

-

Model Number:

-

TC-200

-

Dimensions(L*W*H):

-

700*620*1600MM

-

Weight:

-

210 KG

-

Product name:

-

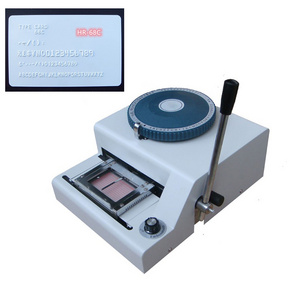

credit card printer and embosser automatic pvc card embossing machine

-

Machine Type:

-

EMBOSSING MACHINE

-

Hot stamping size:

-

200*150MM

-

Air Pressure:

-

0.6-0.8 Mpa

-

Operation:

-

Pneumatic

-

System control:

-

automatic

-

Stamping speed:

-

1300 PCS/H

-

After Warranty Service:

-

Spare parts

Quick Details

-

Condition:

-

New

-

Plate Type:

-

Letterpress

-

Color & Page:

-

Multicolor

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LC

-

Model Number:

-

TC-200

-

Dimensions(L*W*H):

-

700*620*1600MM

-

Weight:

-

210 KG

-

Product name:

-

credit card printer and embosser automatic pvc card embossing machine

-

Machine Type:

-

EMBOSSING MACHINE

-

Hot stamping size:

-

200*150MM

-

Air Pressure:

-

0.6-0.8 Mpa

-

Operation:

-

Pneumatic

-

System control:

-

automatic

-

Stamping speed:

-

1300 PCS/H

-

After Warranty Service:

-

Spare parts

product information

This hot stamping machine is fit for stamping on the surface of plane and round objects.With fast speed and low energy consumption. Mainly applied to the field of craft, fabric handbag, leather, glass, paper and plastic.

|

Model Number

|

TC-250K

|

hot Stamping plane plate size

|

200*150mm

|

|

cylinder size

|

¢ 70mm

|

Max stamping pressure

|

4900N

|

|

Max.stamping speed

|

1000 pcs/hr

|

Machine Dimensions

|

700*800*1700mm

|

|

Stamping pressure range

|

-≤1000kgf

|

power supply

|

220V SINGLE Phase

|

Function

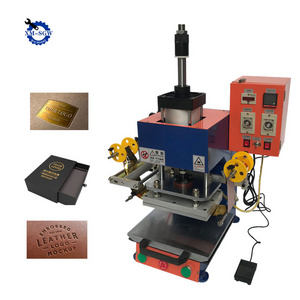

1. With the crank design,which has powerful stamping pressure and little consumption of air pressure.

2. Worktable is adjustable in front-back,left-right direction and revolvable,which ensures the quick and safe operation.

3. Stamping pressure,temperature and time are adjustable.

4. Automatic foil feeding and rolling with adjustable function.

5. Height of the stamping head is adjustable.

1. With the crank design,which has powerful stamping pressure and little consumption of air pressure.

2. Worktable is adjustable in front-back,left-right direction and revolvable,which ensures the quick and safe operation.

3. Stamping pressure,temperature and time are adjustable.

4. Automatic foil feeding and rolling with adjustable function.

5. Height of the stamping head is adjustable.

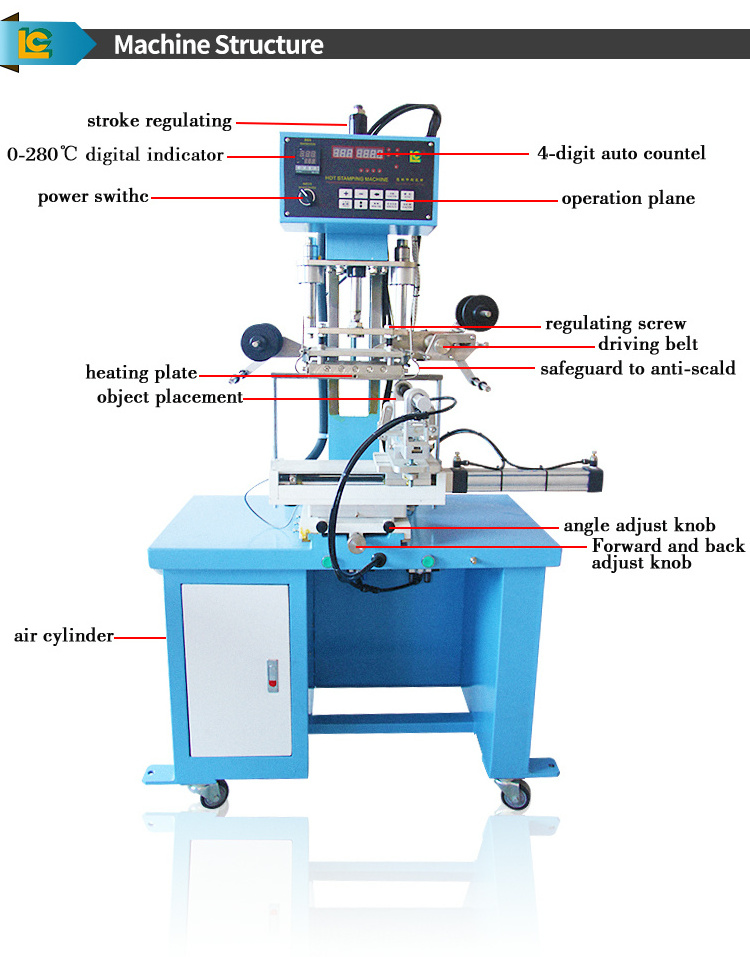

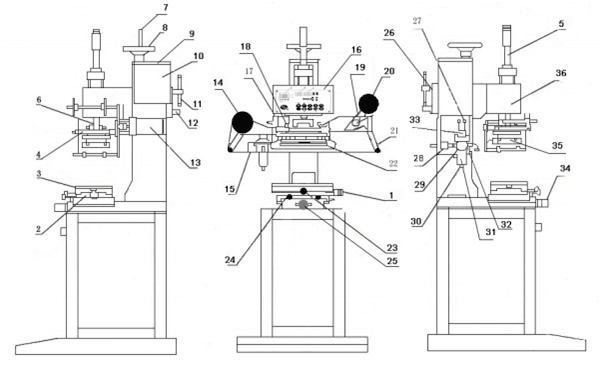

Machine Details

|

Main Structure

1. Working table micro-adjustment knob 2.Lower Guide Board 3. Worktable Board

4. Main roller of receiving foil 5. Stamping cylinder 6. Axis

7. Hand Wheel 8. Up-and down screw rod 9.Up and down aboard

10.up and down seat ked 11.Locking Screw Knob 12.Worktable Rotating

13.foil motor 14.Stamping Release Wheel 15.Left Pull Bar

16.control box 17.rod of up and down 18.adjustment screw

|

|

19.Paper Collecting belt 20.paper collecting wheel 21.Right Pull Bar

22.safe rod 23.Lock Knob of working table 24.Worktable left/right Move Knob 25.worktable front/back knob 26.Stamp head lift speed knob 27.Manual sliding valve

28.Press button 29.air pressure meter 30.switching of removing water

31.water glass 32.water/ oil separating cup 33.pressure adjustment knob 34.Side gap adjust screw 35.stamping aboard 36.stamping head |

|

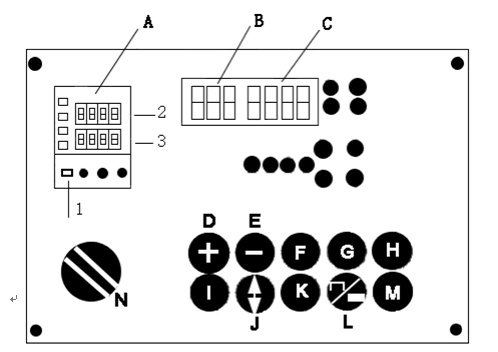

Operation of controlpanel

|

|

Foil collecting roller

|

|

electric motor

|

Heat plate

|

|

Hot stamping flat workbench

|

Hot stamping curved workbench

|

Related Products

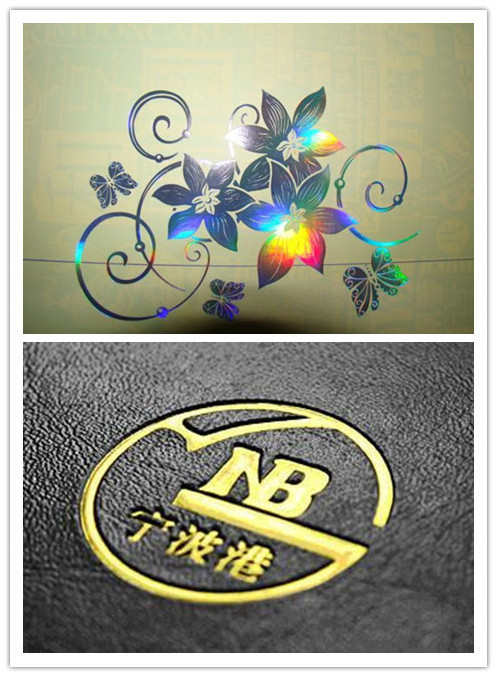

Stamping foil

Stamping fixture

The bronzing fixture is used to fix the load so that it does not shake randomly

Silicon rubber plate

Printing Sample

Our TC-250K hot stamping machine is dual-use, suitable for hot stamping of many products.

Here is not for example one by one.

Feedback

company information

Packaging & Shipping

FAQ

Hot Searches