- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Shangdian

-

Product name:

-

Stainless Steel Casting Dn20-Dn300 Industrial Ball Valve

-

Material:

-

stainless steel/cast steel

-

Size:

-

DN15-DN350

-

Medium:

-

Water oil gas

-

Nominal pressure(PN):

-

16

-

Standard or Nonstandard:

-

Standard

-

Connection:

-

Flange Ends

-

Temperature:

-

-29℃~250℃

Quick Details

-

Port Size:

-

DN15-DN350

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

Q41F46-16C

-

Brand Name:

-

Shangdian

-

Product name:

-

Stainless Steel Casting Dn20-Dn300 Industrial Ball Valve

-

Material:

-

stainless steel/cast steel

-

Size:

-

DN15-DN350

-

Medium:

-

Water oil gas

-

Nominal pressure(PN):

-

16

-

Standard or Nonstandard:

-

Standard

-

Connection:

-

Flange Ends

-

Temperature:

-

-29℃~250℃

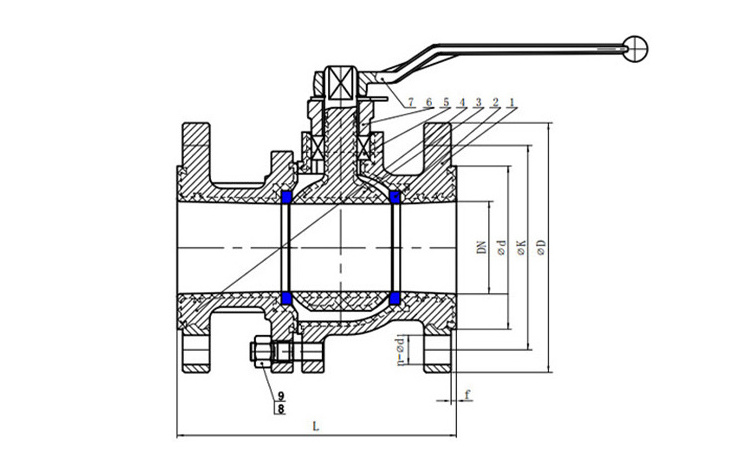

Product Information

Fluorine lined ball valve uses a ball with a circular through-hole as the opening and closing element. The ball rotates around the center line of the valve body with the valve stem to achieve valve opening and closing. Adopting a special molding process to make the sealing surface dense and good, coupled with the V-shaped PTFE packing combination, the valve achieves zero leakage; The ball and valve stem are cast together, eliminating the possibility of the valve stem being pushed out of the pressure bearing part due to pressure changes, fundamentally ensuring safety during use; Adopting a fully plastic lining process, it is resistant to strong corrosion from media.

|

Product name

|

Fluorine lined ball valve

|

|

Availably Size

|

DN15-DN350

|

|

Nominal pressure(PN)

|

16

|

|

Body material

|

Stainless steel/cast steel

|

|

Connection type

|

Flange

|

|

Model

|

Q41F46-16C

|

|

Structural style

|

Floating ball valve

|

|

Diameter

|

Inch

|

Thread diameter

|

|

DN6

|

1/8

|

9.5

|

|

DN8

|

1/4

|

12.5

|

|

DN10

|

3/8

|

16

|

|

DN15

|

1/2

|

20

|

|

DN20

|

3/4

|

25.5

|

|

DN25

|

1

|

32

|

|

DN32

|

1-1/4

|

40.5

|

|

DN40

|

1-1/2

|

46

|

|

DN50

|

2

|

58

|

|

DN65

|

2-1/2

|

74

|

|

DN80

|

3

|

86

|

|

DN100

|

4

|

112

|

Product Show

Product Feature

1.Full port standard FEP lined ball valves offer high stability, rigidity and eliminating potential leak path.

2.Full port design minimizes pressure losses and increases flow capacities thus reducing energy and pumping costs.

3.Full bore design almost no fluid resistance, and good shut-off performance.

4.It features zero leakage, maintenance-free, one-piece stem and ball design, high sealing performance and can be used under full vacuum service.

2.Full port design minimizes pressure losses and increases flow capacities thus reducing energy and pumping costs.

3.Full bore design almost no fluid resistance, and good shut-off performance.

4.It features zero leakage, maintenance-free, one-piece stem and ball design, high sealing performance and can be used under full vacuum service.

Product Application

widely used in chemical plant,petroleum ,chlor-alkali, steam etc.

More Product

Packing & Delivery

Hot Searches