- Product Details

- {{item.text}}

Quick Details

-

Fineness:

-

10-15um

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

TEX

-

Model Number:

-

3K 6K 12K 24K 25K 48K 50K

-

Filament Number:

-

3K 6K 12K 24K 25K 48K 50K

-

Linear Density:

-

360, 720, 1440, 2990

-

Linear Density of Monofilament:

-

0.122+/-0.003tex

-

Linear Density Deviation From Nominal:

-

Max.+/-5%

-

Tensile Strenght for Single Fiber:

-

Min.58 Cn/Tex

-

Elongation at Break:

-

12+/-3%

-

Oil Content:

-

1.2+/-0.5%

-

Humidity:

-

<0.1%

-

Transport Package:

-

Cartons

-

HS Code:

-

5503300000

Quick Details

-

Use:

-

Filling Material, Spinning, CONCRETE

-

Material:

-

Polyacrylonitrile Fiber Acrylic Fiber

-

Fiber Length:

-

3K 6K 12K 24K 25K 48K 50K

-

Fineness:

-

10-15um

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

TEX

-

Model Number:

-

3K 6K 12K 24K 25K 48K 50K

-

Filament Number:

-

3K 6K 12K 24K 25K 48K 50K

-

Linear Density:

-

360, 720, 1440, 2990

-

Linear Density of Monofilament:

-

0.122+/-0.003tex

-

Linear Density Deviation From Nominal:

-

Max.+/-5%

-

Tensile Strenght for Single Fiber:

-

Min.58 Cn/Tex

-

Elongation at Break:

-

12+/-3%

-

Oil Content:

-

1.2+/-0.5%

-

Humidity:

-

<0.1%

-

Transport Package:

-

Cartons

-

HS Code:

-

5503300000

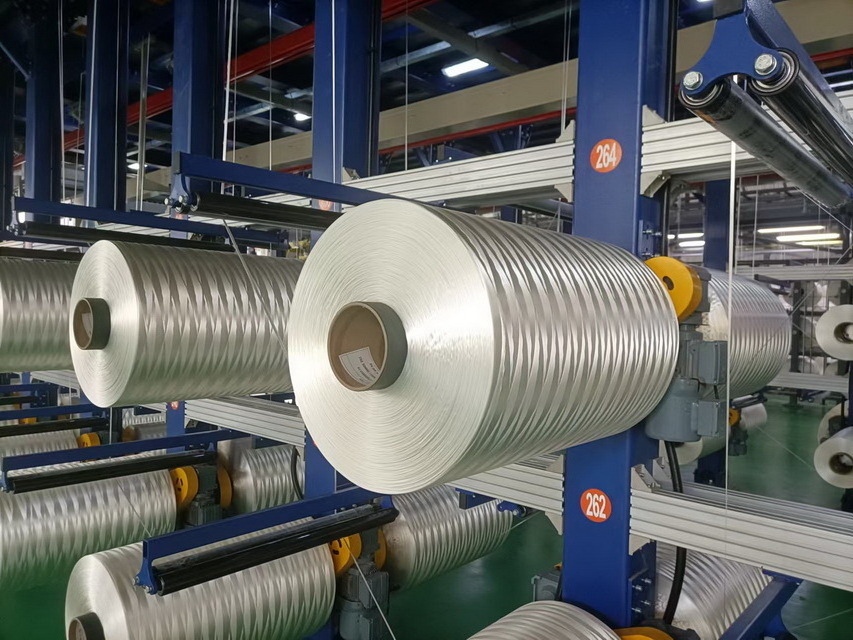

Manufacturing of PAN Precursor Fibers, Pan-based carbon fibers

Offering industry-leading PAN-based carbon fiber designed for superior, cost-effective performance. This material is perfect for a variety of carbon fiber applications .

Unlike pitch-based fibers, PAN-based carbon fiber is created with a synthetic fiber called polyacrylonitrile (PAN) . Though it is technically considered a thermoplastic, it has a much higher melting point and can be created with both dry and wet spinning methods . While pitch-based options have a higher modulus of elasticity (stiffness) and are often more costly, PAN-based carbon fiber has a greater ability to absorb mechanical energy (toughness) and is traditionally more cost-effective.

Similar to other versions of carbon fiber, PAN-based solutions must go through specialized stabilizing, carbonizing, surface treatment and sizing. This process results in fibers that can vary in elasticity modulus and strength, depending on the heat treatment.

The high strength, superior stiffness, the light weight of carbon fibers have made them the dominant reinforcing fibers used in high-performance polymer matrix composites. However, the same fibers can also reinforce brittle materials, such as ceramics and carbon, thus creating a unique class of high-temperature composite materials. When properly protected from oxidation, these carbon fiber-carbon matrix composites can withstand extended exposure to temperatures of up to 2500C, making them attractive for many aerospace applications. In addition, because of their improved friction performance and high wear resistance, carbon-carbon materials are used in high-performance brakes of aircraft and racing cars. Using these CC brakes in passenger cars and trucks is currently being evaluated.

At present, all commercial carbon fibers are produced by the thermal decomposition of various organic fiber precursors. The most popular precursor materials are fibers of polyacrylonitrile (PAN), cellulos (Rayon), and pitch. A proposed alternate process, which produces a discontinuous, high-performance carbon fiber, is called vapor-growth. The chapter describes the similarities of these four fiber processes and discusses their differences.

Manufacture of PAN-based carbon fibers:

Today, approximately 90% of all the commercial carbon fibers are produced from a PAN precursor fiber. Normally, Pan is copolymerized with a small amount of another monomer, such as methylacrylate, to lower its glass transition temperature and control its oxidation rate. Figure 1 lists a few of the many monomers copolymerized with acrylonitrile to produce commercial PAN precursor fibers. Typically, the precursor fiber would contain 93-95 present acrylonitrile units, with the remainder being one or more of these monomers. Because PAN docomposes below its melt temperature, it is normally extruded into filament from using various solution spinning techniques.

Solution spinning of PAN precursor fibers;

Melt-assisted spinning of PAN precursor fibers;

Oxidation of PAN precursor fibers;

Carbonization and graphitization process;

Both the final heat treatment and the degree of molecular orientation of the molecules in the thermoset precursor fiber govern the modulus of the final carbon fiber product. As in all brittle materials, structural flaws limit the strength of the final carbon fiber. Thus, the purity in the precursor fiber, the final carbonization conditions, and even the void content of the precursor fiber can influence the strength of the final carbon fiber.

After final heat treatment, most PAN-based carbon fibers are given a surface treatment to improve their bonding with polymeric matrix materials. Although surface treatment results in some roughening of the surface, its primary effect is to increase the concentration of oxygenated groups on the fiber surface. Various techniques can accomplish this: exposing the carbon fiber to gases (such as air or carbon dioxide) at elevated temperature, submerging the fiber in sodium hypochlorite or nitric acid solutions, or electrolytically etching the fiber. The principal goal of thie process step is to increase the interfacial bond strength between the fiber and the matrix material and, thus, improve the interlaminar shear strength of the composite.

After being surface-treated, a small amount of size is added to improve the wettability of the carbon fiber, Normally, this size is a low molycular weight from of the anticipated matrix polymer. In other words, epoxy-sized fiber is coated with a low molycular weight expoxy. It should be mentioned that the primary objective of this size is to improve the wettability of the fiber, not to improve its handleability. Therefore, even sized fibers can be difficult to handle during perform weaving and composite fabrication.

Carbon fiber PAN precursor/Acrylic fiber for carbon fiber is high purity and high strength fiber through wet-two step method with solvent DMF and surface finishing size treatment.It has higher elastic modulus,tensile strength and anti-UV properties,anti-high temperature and cold performance.It is the best raw material of PAN carbon fiber Via Pre-oxidation(200~300ºC),carbonization(1000~1500ºC), Graphitization(2500~3000ºC).

SPECIFICATIONS:

| MODEL | TEX |

| FILAMENT NUMBER |

3K 6K 12K 24K 48K 50K

|

| LINEAR DENSITY | 360tex 720tex 1440tex.. |

|

LINEAR DENSITY

OF MONOFILAMENT |

0.122

±0.003tex |

|

LINEAR DENSITY

DEVIATION FROM NOMINAL |

Max.±5% |

|

TENSILE STRENGHT

FOR SINGLE FIBER |

Min.58 cN/tex |

| ELONGATION AT BREAK | 12±3% |

| OIL CONTENT | 1.2±0.5% |

| HUMIDITY | ≤0.1% |