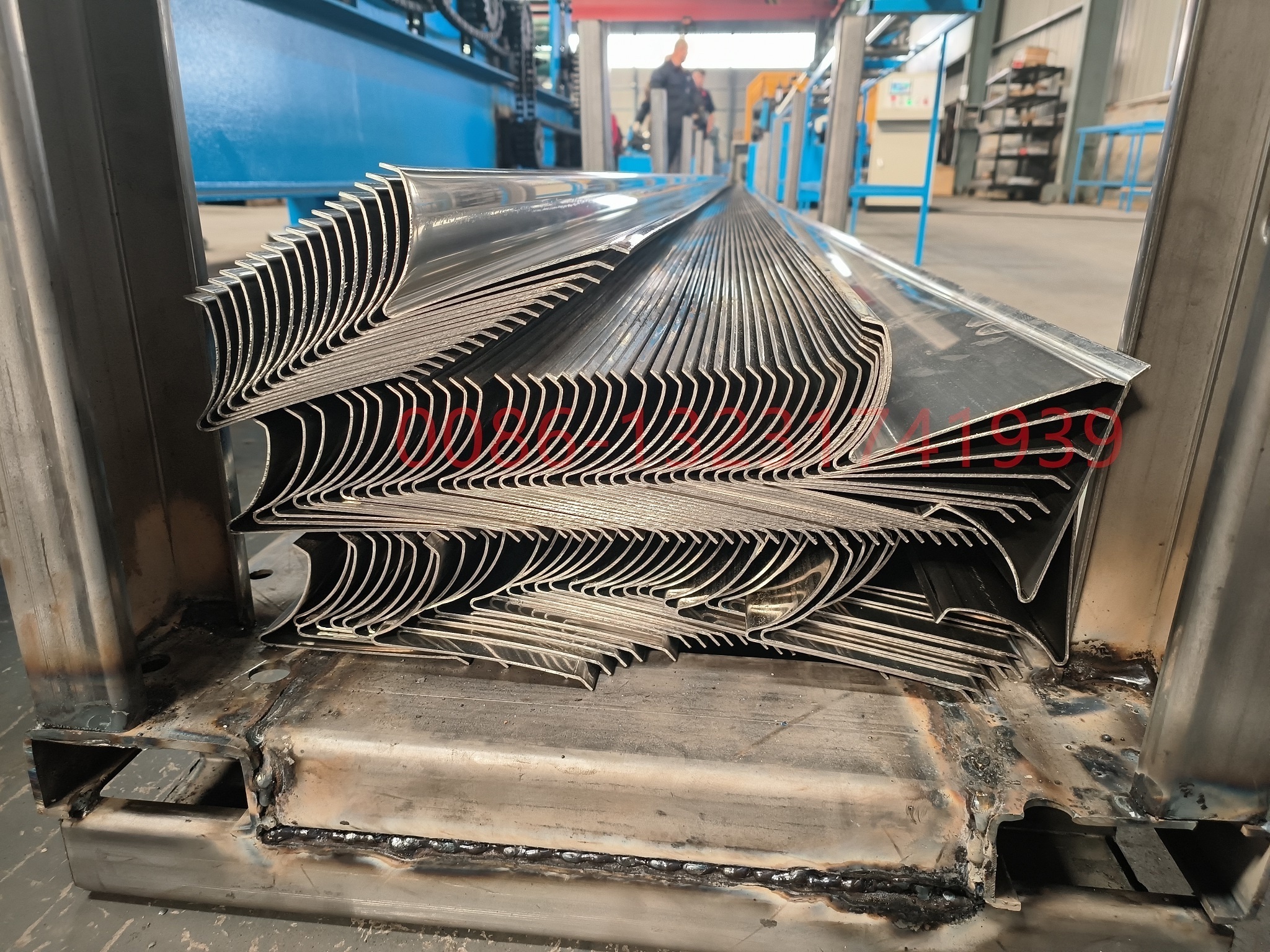

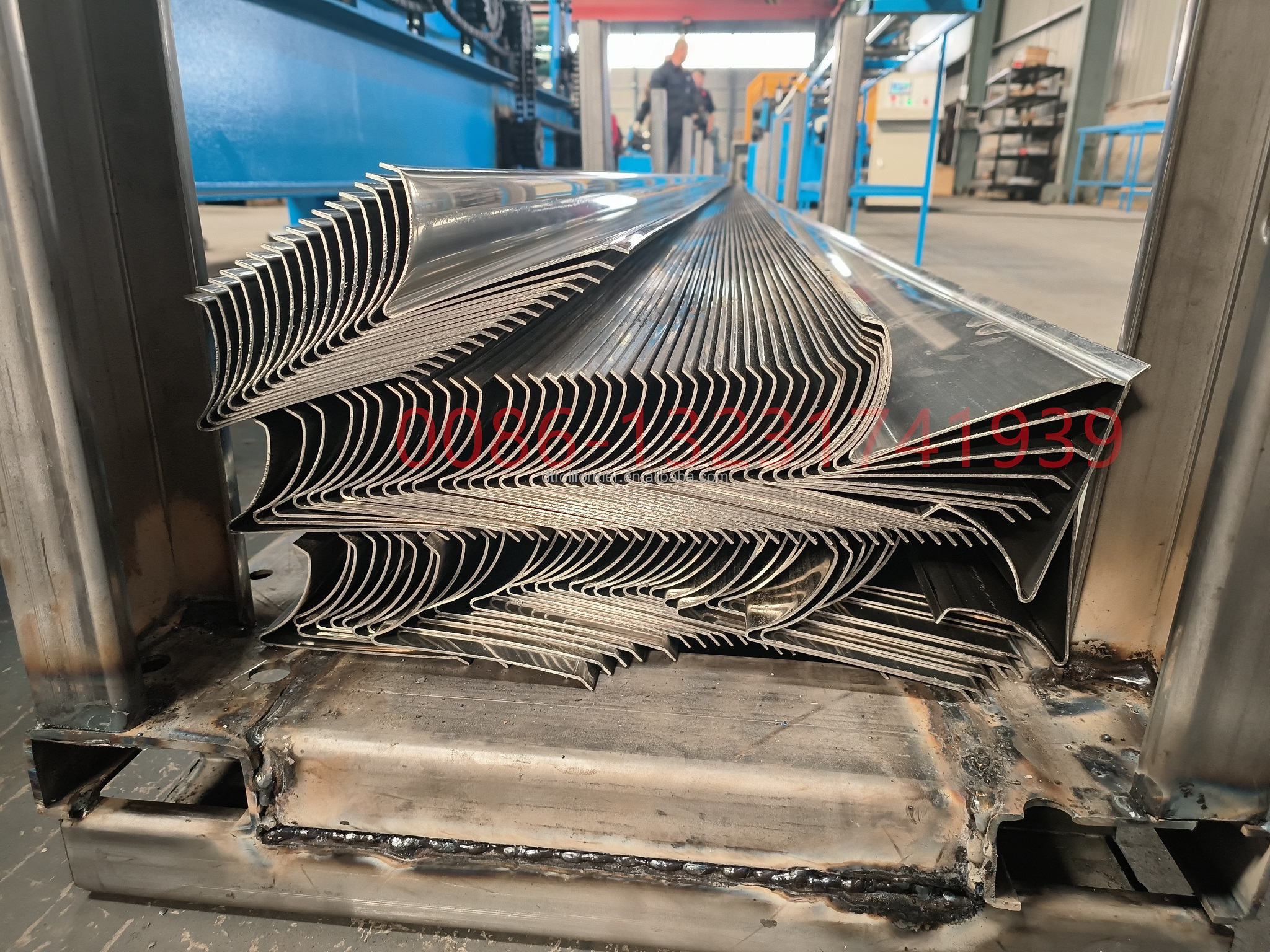

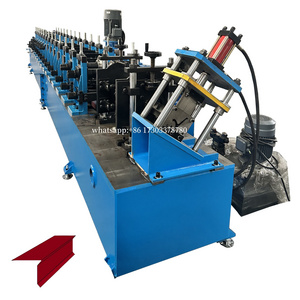

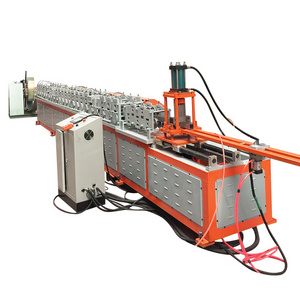

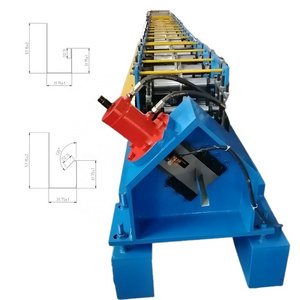

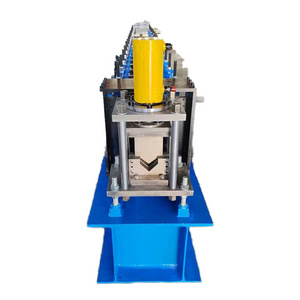

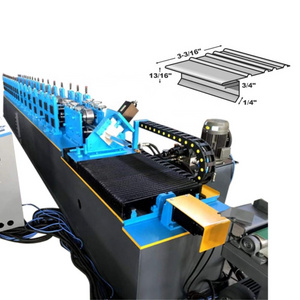

A Drip Edge Roll Forming Machine is a specialized piece of equipment used in the construction and roofing industry to produce drip edges, which are essential components for roof installations. Drip edges are metal strips that are installed along the edges of a roof to protect it from water damage and help direct rainwater away from the structure. These machines automate the process of manufacturing drip edges by continuously forming and shaping metal sheets into the desired profiles.

Our metal drip edge roll forming machine can be customized as your needed profile drawing .

WHAT IS DRIP EDGE AND DRIP EDGE MATERIAL

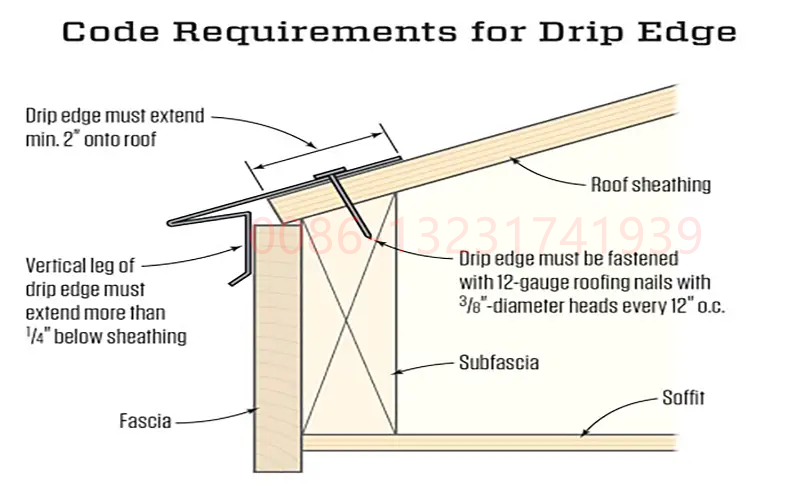

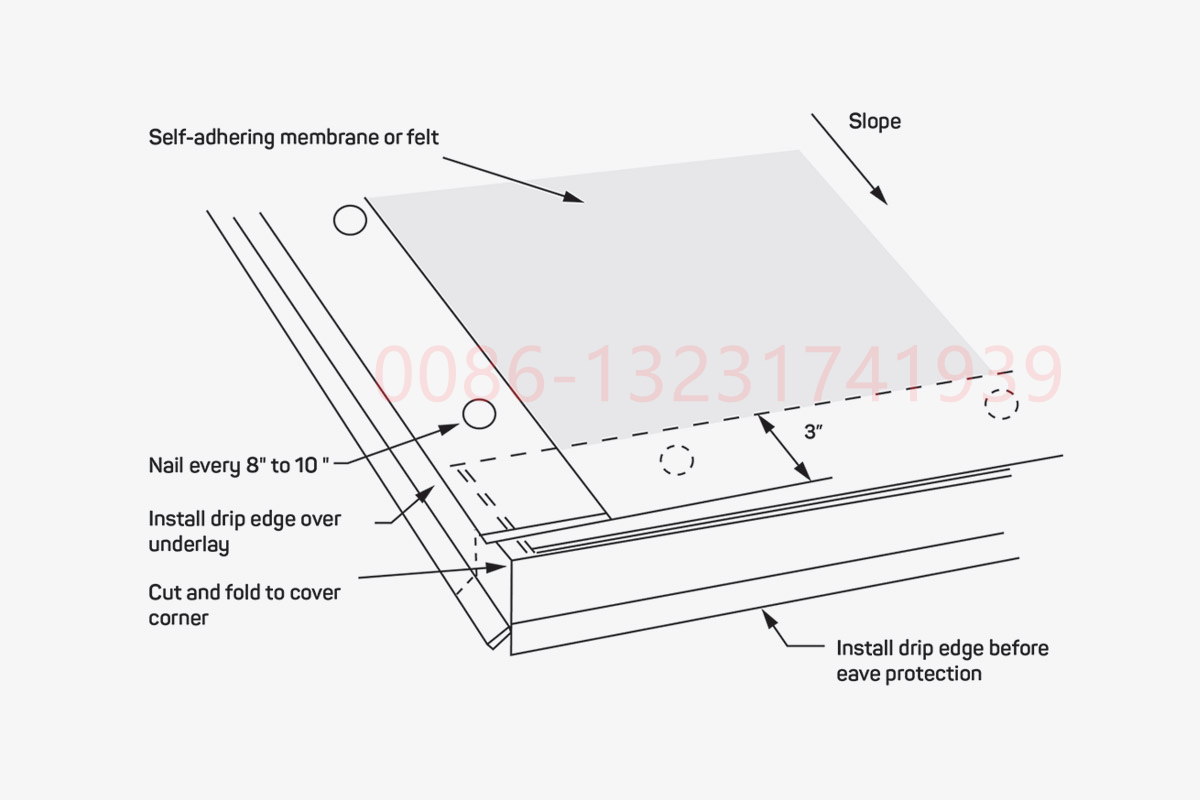

Drip edges are metal sheets, usually shaped like an “L,” installed at the edge of the roof. Also called drip edge flashing or D-metal, they serve a vital function by directing water away from the fascia and into the gutter. Without a drip edge, water may end up beneath the shingles and may cause damage to various parts of the home. Though your home may not have originally had a drip edge installed, drip edges are now required by most building codes across North America to protect homes from damage.

Roof drip edges are generally sold in 10.5-foot lengths, but they are occasionally sold in 8-foot lengths or smaller. The length of the overhang itself commonly ranges from 2 to 5 inches. You may find other styles and sizes of drip edges in the store, including “J-channel” drip edges, but these are intended for windows, doors and other applications.

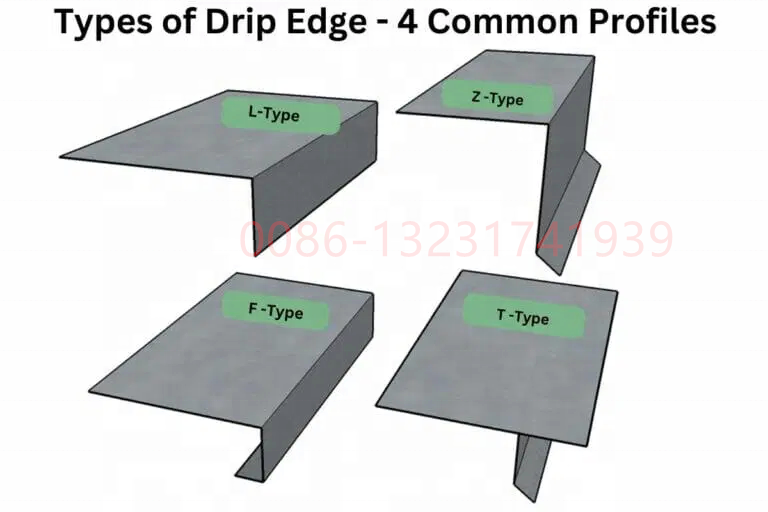

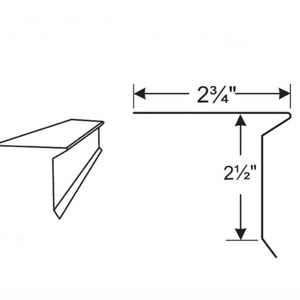

Type C: This is the classic“L”-shaped drip edge, sometimes called “L style.” This drip edge is bent to a 90-degree angle and has a lower flange at the bottom.

Type D: This profile of drip edge is shaped like a “T,” with a lower flange at the bottom. Sometimes it is called drip

metal, “D-metal” or “T style.” The Asphalt Roofing Manufacturers Association (ARMA) prefers this drip edge profile to Type C because it keeps the water further away from the fascia. However, Type C is still acceptable according to most building codes.

Type F: This is an extended drip edge that has a longer leading edge, which is useful when installing new drip edges over

existing shingles or on rake edges. This profile is frequently called “F style” or “gutter apron.”

Aluminum: A common material for drip edges, aluminum isn’t as strong as steel. It doesn’t corrode and is often sold in colors that match the rest of the home exactly.

Galvanized steel: Drip edges are designed to be in contact with water; so, if they are made of steel, they need to be galvanized to prevent rust. Minimum 24-gauge steel is preferable so that the drip edge can withstand strong winds.

Copper: Copper is a sturdy metal that gives a roof a unique look. When used as a drip edge, it should be a minimum of 0.69 mm or 20 ounces.