- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

impact plates, blow bar, hammer

-

Product Keywords:

-

impact crusher parts blow bar

Quick Details

-

Place of Origin:

-

China

-

Application:

-

Quarry

-

Name:

-

Impact crusher parts

-

Product name:

-

impact plates, blow bar, hammer

-

Product Keywords:

-

impact crusher parts blow bar

1.Emply the external refining technology, effectively reduced the harmful elements, impurity and oxygen and hydrogen harm, greatly enhanced the abrasion resistance and impact toughness of the steel of blow bars.

2.Using proprietary metamorphic agent for modification treatment, fine grains, improve carbide configuration and distribution, and to improves the abrasion resistance and tenacity.

3.Optimizing heat treatment process, make the product of uniform hardness especially, impact abrasion resistance becoming stronger.

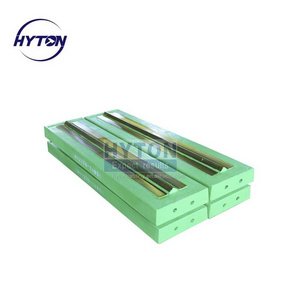

4. Manufactured with hypereutectic super high chromium, our blow bar has a service life 50~100% longer than those made of traditional high chromium iron. The special processing techniques ensure that our flat hammer has leading performance.

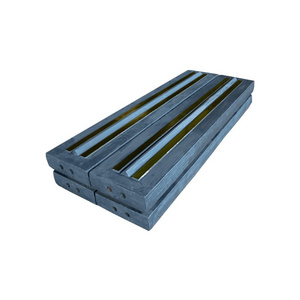

Impact crusher hammers:(material: Cr26NiMo)

Impact crusher plates:(material: Cr26NiMo)

Cone crusher mantle and concave ( Mn18Cr2)

Jaw crusher plates: (Mn13Cr2)

Production factory

Loading and delivery

1. Q: What kinds of products do you offer?

A: We provided parts are mainly related to your plant machine. It ranges from the drill

rod,excavator buckets and wheel loaders, crusher spare parts, construction machinery parts, brass

bush, conveyor and screen spare parts, beneficial equipment spare parts, grinding mill

spare parts, machining spare parts and other customized spare parts.

2. Q: What kind of materials are you familiar with?

A: We are familiar with carbon steel, alloy steel, standard wearing plate, high manganese steel, high

chrome steel, martensitic steel, casting iron, and bronze.We have begun to research ceramic insert

material technology.

3. Q: What’s the maximum single weight that can be casted? What is your processing

capacity per day ?

A: The single weight that can be casted at one time is 13 metric tons. The capacity is 80 tons per

working day.

4. Q: Can you use foundry machining castings ?

A: Yes, the CNC machine can machine material hardness from HB200 to HRC62.The maximum

machining length is 8m and maximum width is 4m.

5. Q: What information do we need to provide to you in order to confirm our parts order?

A: We work with technical drawings for any non-standard products. If the order is for standard parts,

you only have to provide us with the part number so we may define the parts of the order.

6. Q: May we visit the factory?

A: Yes, you can visit the factory during working days and our sales team would he happy to assist you.

It is possible, to take the high speed train from Shanghai station to the factory and we can pick up

you at the airport or train station.