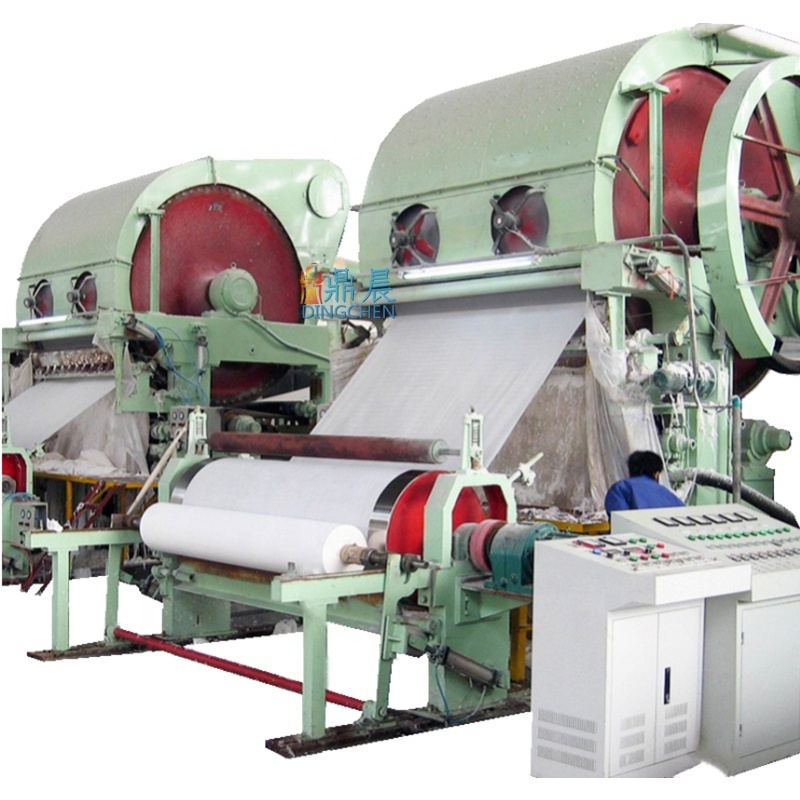

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1300 kg

Quick Details

-

Production Capacity:

-

15 Ton Per Day

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DINGCHEN

-

Weight:

-

1300 kg

|

No.

|

Item

|

Function

|

|

Pulp Making Section

|

||

|

1

|

High Consistency Hydra-pulper

|

To break the waste paper or wood pulp into pulp and drop down the impurity and ink

|

|

2

|

High frequency vibrating screen

|

To separate and remove the small impurity(such as broken plastic tape,staples,etc) in the pulp through vibrating

|

|

3

|

High speed pulp washer

|

To whiten the pulp through bleaching

|

|

4

|

Pulp refiner

|

To grind pulp fiber

|

|

5

|

Low concentration pulp cleaner

|

To remove the sand and tiny impurity in the water and pulp

|

|

6

|

Pressure screen

|

To screening pulp fiber

|

|

7

|

Impeller

|

To stir the pulp and make sure the pulp and water mixed well

|

|

8

|

Pulp pump

|

To provide the pulp for the needed machine

|

|

Paper Making Section

|

||

|

9

|

Crescent type hydraulic headbox

|

Spray pulp fiber to forming wire evenly

|

|

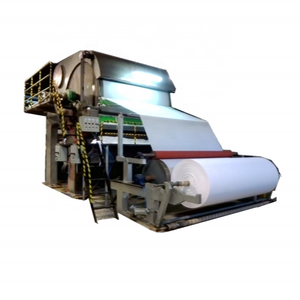

10

|

Crescent former

|

To forming wet paper web

|

|

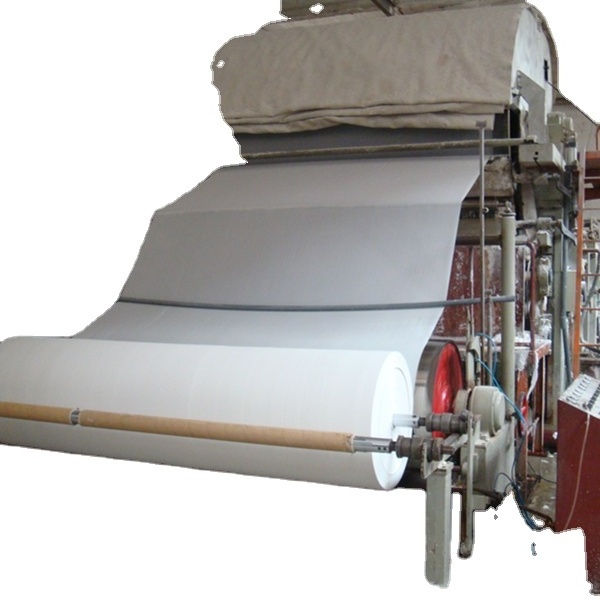

11

|

Dryer section part

|

To dry wet paper

|

|

12

|

Winding part

|

To reeling output paper be a jumbo paper roll

|

|

Boiler Section

|

||

|

13

|

Gas/diesel/coal boiler

|

To provide high temperature and pressure steam to dryer to dry paper

|

Pre-sales services:

1) Offering comprehensive technical and business consultation services;

2) Proposing the most suitable scheme and equipment for our clients;

3) Designing and fabricating targeted products according to the special requirements of clients;

4) Training periodically high qualified service technician.

5) Adopt all-around computer aided design (CAD) to design the whole production line.

6) Provide all-around turn-key projects as follows: production design,equipment manufacture, installation and adjustment, technical service,

7) Complete sets machine will be pre-installed and tested to confirm that the machine are in good condition before delivery.

8) On time delivery.