- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Macsensor

-

Model Number:

-

water level sensor

-

Material:

-

stainless steel

-

Mode:

-

level measurement

-

Measuring Range:

-

0-1..100m mH20 or by customized

-

Output signal:

-

4-20mA, 0-10V, 0.5-4.5V Ratiometric, SDI-12, RS485 Modbus RTU

-

Accuracy:

-

0.5% or 0.25%

-

Power supply:

-

ask a customized

-

Measuring liquid:

-

Water, oil, or others

-

Type:

-

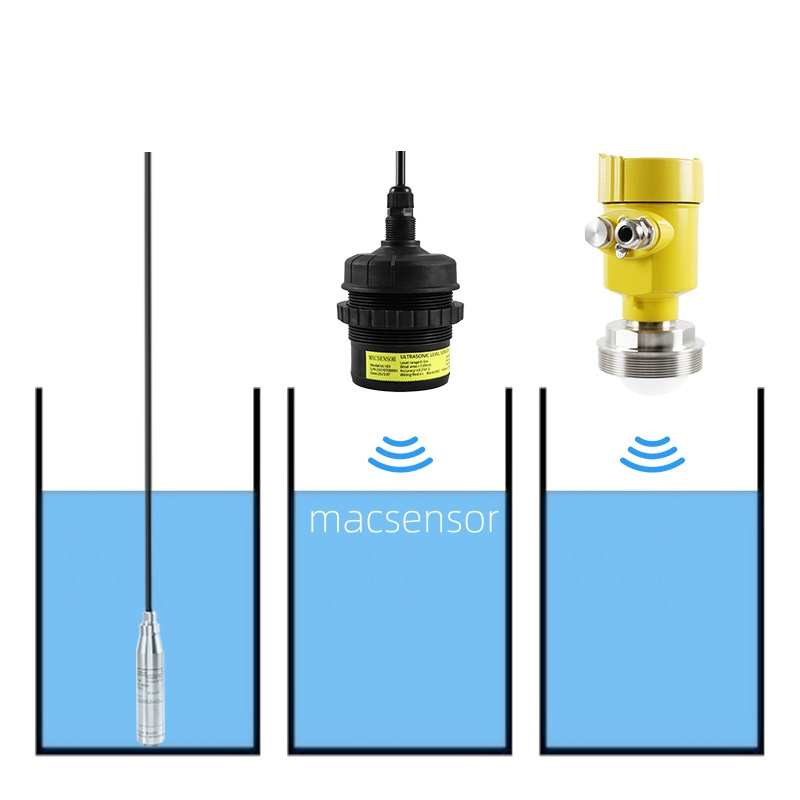

Non-contact or submersible

-

Working temperature:

-

Max.100℃

-

Protection:

-

IP68/IP67

-

Measurement:

-

Contact or Non-Contact

-

Product name:

-

Liquid Level Sensor Transmitter Indicator

Quick Details

-

Grade:

-

Industrial

-

Warranty:

-

12 months

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

Macsensor

-

Model Number:

-

water level sensor

-

Material:

-

stainless steel

-

Mode:

-

level measurement

-

Measuring Range:

-

0-1..100m mH20 or by customized

-

Output signal:

-

4-20mA, 0-10V, 0.5-4.5V Ratiometric, SDI-12, RS485 Modbus RTU

-

Accuracy:

-

0.5% or 0.25%

-

Power supply:

-

ask a customized

-

Measuring liquid:

-

Water, oil, or others

-

Type:

-

Non-contact or submersible

-

Working temperature:

-

Max.100℃

-

Protection:

-

IP68/IP67

-

Measurement:

-

Contact or Non-Contact

-

Product name:

-

Liquid Level Sensor Transmitter Indicator

Which Water Tank Liquid Level Monitor Sensor Meter Transmitter

Can Meet Your Demand?

Find out the right one with Macsensor professional team now!

FAQ

How to Select a Water Level Sensor?

1. Define Your Application Requirements:

* Determine the purpose of the water level measurement. Are you monitoring water levels in a well, tank, river, or other water bodies?

* Specify the measurement range required . How deep or high do you need to measure the water level?

* Consider the type of water or liquid you are measuring. Is it clean water, wastewater, chemicals, or another fluid?

* Identify any environmental factors, such as temperature extremes, humidity, or the presence of dust or chemicals.

* Determine the purpose of the water level measurement. Are you monitoring water levels in a well, tank, river, or other water bodies?

* Specify the measurement range required . How deep or high do you need to measure the water level?

* Consider the type of water or liquid you are measuring. Is it clean water, wastewater, chemicals, or another fluid?

* Identify any environmental factors, such as temperature extremes, humidity, or the presence of dust or chemicals.

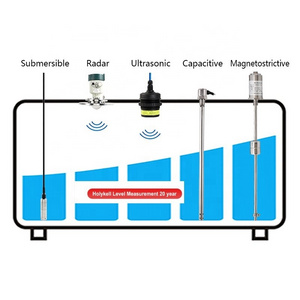

2. Select the Sensor Type:

Consider Installation Requirements

* Determine whether the sensor will be installed in a submersible or non-submersible manner. Submersible sensors are immersed in the liquid, while non-submersible sensors (ultrasonic or radar level sensor) are installed above the liquid surface.

* Ensure that the installation method aligns with your application and is feasible in your setup.

* Ensure that the installation method aligns with your application and is feasible in your setup.

Evaluate Accuracy and Resolution:

Check the accuracy and resolution specifications of the sensor. Higher accuracy may be required for critical applications,

while lower accuracy may suffice for less critical ones.

while lower accuracy may suffice for less critical ones.

Environmental Considerations:

Verify that the sensor can withstand the environmental conditions at your location, including temperature, humidity, and

exposure to corrosive materials if applicable. You can easily check it with our sales team.

exposure to corrosive materials if applicable. You can easily check it with our sales team.

Output and Communication:

Determine how you want to receive and process the level measurements. Sensors have analog outputs, digital outputs, or communication protocols like 4-20 mA, Modbus, or RS-485.

This ensure compatibility with your data acquisition system.

Power Requirements:

Consider the power source available at the installation site. Sensors may require different voltage levels or power supplies.

Cost and Budget:

Evaluate the cost of the sensor and ensure it fits within your budget. Keep in mind that different technologies and features

can significantly impact the price.

can significantly impact the price.

If you are unsure about which sensor to select, consult with our experts to get recommendations based on your specific application.

Just easily send an inquiry below now!

Product Parameter

|

Technology

|

Pressure senor

|

Ultrasonic

|

80G Hz Radar

|

Wireless

|

|

Model

|

L703

|

UL103

|

MQ8

|

MZW2603

|

|

Level Range

|

0-1..100m mH20 (Special by customized)

|

2.5m, 5m, 10m, others on request

|

0.1~120m

|

0-1m... 50m level by customized

|

|

Output

|

4-20mA, 1-5V, 0-5V, 0-10V, 0.5-4.5V Ratiometric, SDI-12, RS485 Modbus RTU

|

RS485+4~20mA; RS485+0~5V

|

4~20mA ( with HARTbus) or RS-485

|

GPRS/3G/4G/LoRa/LoRaWAN

|

|

Power Supply

|

12-36Vdc/10-36Vdc/15-36Vdc/5Vdc/10-30Vdc

|

10-30VDC(5-30VDC by customized)

|

18-28VDC

|

DC 3.6V, 19Ah Li-Battery

|

|

Accuracy

|

≤±0.5%F.S,≤±0.25%F.S(by customized)

|

0.25%F.S, 0.5%F.S optional

|

±1mm/±2mm

|

0.5% F.S

|

|

Working Temp

|

-30°C...70°C or -30°C...100°C (Customized)

|

-10...50℃(-40...80℃ by customized)

|

-4...85°C

|

30℃...70℃

|

|

Protection

|

IP68

|

IP67

|

IP68

|

IP68

|

|

Key Features

|

Submerged for continuous level monitoring, Commonly used in wastewater management, environmental monitoring, and industrial

processes. |

Non-contact measurement using ultrasonic waves, suitable for applications where direct contact is impractical.

|

The higher frequency allows for better performance in complex environments and with low-reflective substances. Commonly used in

industries like chemical processing, oil and gas, and pharmaceuticals. |

Eliminates the need for wired connections, providing flexibility in installation. Suitable for locations where running wires is

challenging or expensive. |

|

Applications

|

Typically used for measuring liquid levels in tanks, wells, reservoirs, and other liquid storage systems.

|

Measures liquid or solid levels in tanks and vessels across various industries. Ideal for water treatment, manufacturing, and

agriculture. |

Ideal for measuring liquid levels in challenging conditions, such as high temperatures, high pressures, or in environments with

dust, foam, or vapor. |

Used for monitoring and transmitting level data wirelessly to a central control system.

|

Recommend Products

Hot Searches