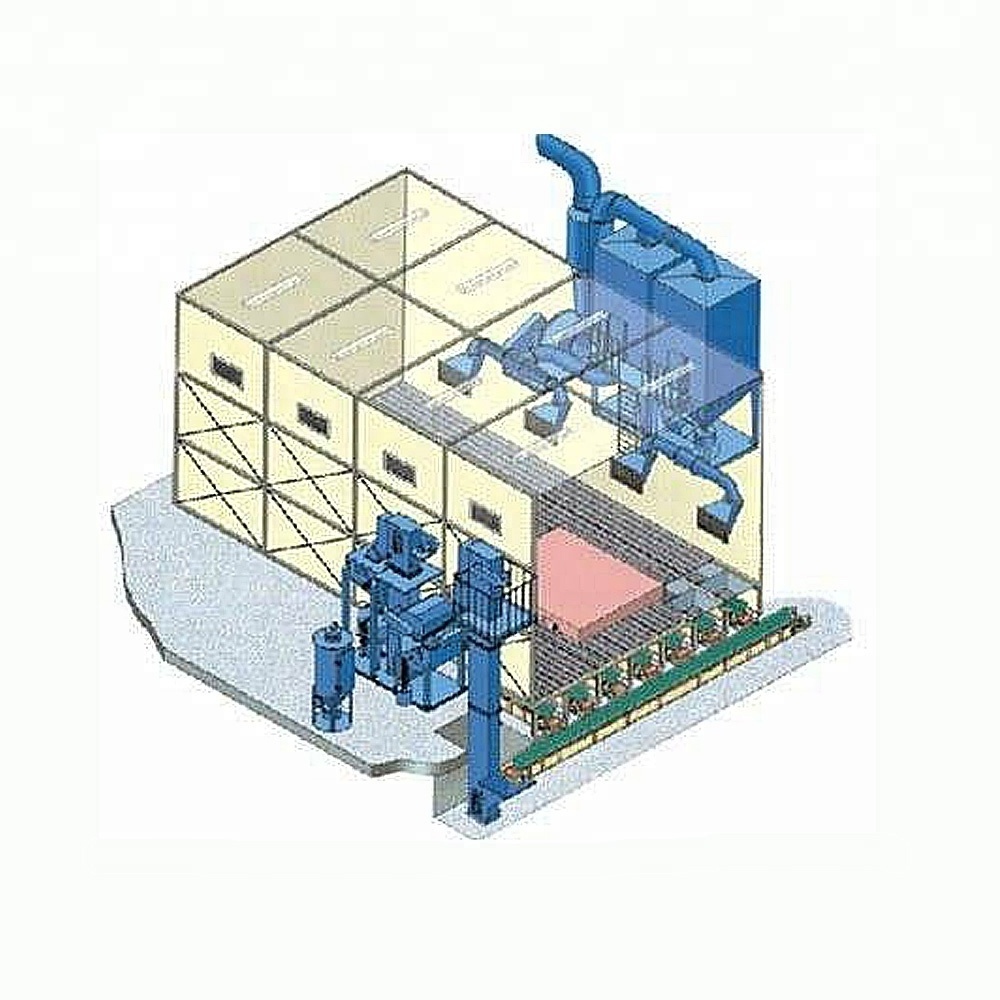

Sandblasting Room is mainly composed of blasting room, sand storage hopper, belt conveyor, bucket elevator, separator, sand

blasting machine, dust removal system, PLC electric control system, maintenance platform, grille, escalator and so on. Sand

blasting room is made of full steel construction, with anti-wear rubber sheet liner, which includes automatic reclaiming abrasives

system and is completed with filter cylinder type dust collector, protective articles, lighting installation and working table

indoors. Be applicable to blasting cleaning for large steel structure. The painting room is made of full steel construction, with

water curtain on the floor to filter paint mist, which includes working table indoors and light system and so on. It features high

purification efficiency of paint mist, low energy consumption, good working environment and so on.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Custom Made

-

Blasting Media:

-

sand

-

Blast gun:

-

Double Gun

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

custom

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

jsours

-

Power:

-

Customised

-

Dimension(L*W*H):

-

Custom Made

-

Blasting Media:

-

sand

-

Blast gun:

-

Double Gun

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

custom

Sandblasting Machine

Product Overview

|

Main parts of powder coating line :

|

|

|

|

1

|

Pretreatment system

|

|

|

2

|

Powder coating booth

|

|

|

3

|

Electrostatic powder coating engine/device

|

|

|

4

|

Moisture drying oven and powder curing oven

|

|

|

5

|

Hot-air circular system

|

|

|

6

|

Electrical control system

|

|

Product specifications

Technological process:

Loading--Predegreasing-Degreasing-Water rinsing 1-Water rinsing 2-Surface conditioning-Parkerising-Moisture drying-Natural cooling- -Powder spraying-Powder curing-Natural cooling-Unloading

Operating principle:

The powder coating machine sprays the powder paint on the surface of the workpiece which will adsorb on the surface evenly to powder coatings under the effect of static electricity. And the powder coatings will level and solidify under high-temperature baking to the final coating. This technology is superior to others in the field of mechanical strength, adhesive force, corrosion resistance and aging resistance.

Product configuration

We specialize in the whole line:

1) Pre-treatment system: Automatic Spraying pre-treatment and dipping pre-treatment are available;

2) Drying oven: Drying oven which drying the water after pre-treatment is designed according to customers' actual conditions.

3) Powder coating spray system: Automatic spray reciprocator, manual spray equipment and Semi-auto (Auto-spraying with manual repairing spraying) are for your choice;

4) Powder recycling system: Cyclone equipment and cartridge filters is customized and introduced according to actual requirement by customer;

5) Curing oven: Tunnel curing oven, bridge type curing oven, Electric power heating curing oven, Gas-heating curing oven, Diesel heating curing oven, High temperature, lower temperature curing oven is available for fitting your sole factory.

6) Conveying system: Various design according to different requirement by customer on the basis of customers' workpiece and output information.

7) Control system: PLC control, with or without touch screen

8) Spray gun and reciprocator

1) Pre-treatment system: Automatic Spraying pre-treatment and dipping pre-treatment are available;

2) Drying oven: Drying oven which drying the water after pre-treatment is designed according to customers' actual conditions.

3) Powder coating spray system: Automatic spray reciprocator, manual spray equipment and Semi-auto (Auto-spraying with manual repairing spraying) are for your choice;

4) Powder recycling system: Cyclone equipment and cartridge filters is customized and introduced according to actual requirement by customer;

5) Curing oven: Tunnel curing oven, bridge type curing oven, Electric power heating curing oven, Gas-heating curing oven, Diesel heating curing oven, High temperature, lower temperature curing oven is available for fitting your sole factory.

6) Conveying system: Various design according to different requirement by customer on the basis of customers' workpiece and output information.

7) Control system: PLC control, with or without touch screen

8) Spray gun and reciprocator

Pre-treatment system

Drying oven

Powder coating spray system

Powder recycling system

Curing oven

Conveying system

Product packaging

|

Packaging

|

|

|

|

Size

|

It depends

|

|

|

Weight

|

It depends

|

|

|

Total shipping weight

|

It depends

|

|

|

Packaging Details

|

The normal package is film and carton. If container is too tigher, we will use pe film for packing or pack it according to

customers special request. |

|

Hot Searches