- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Atcera

-

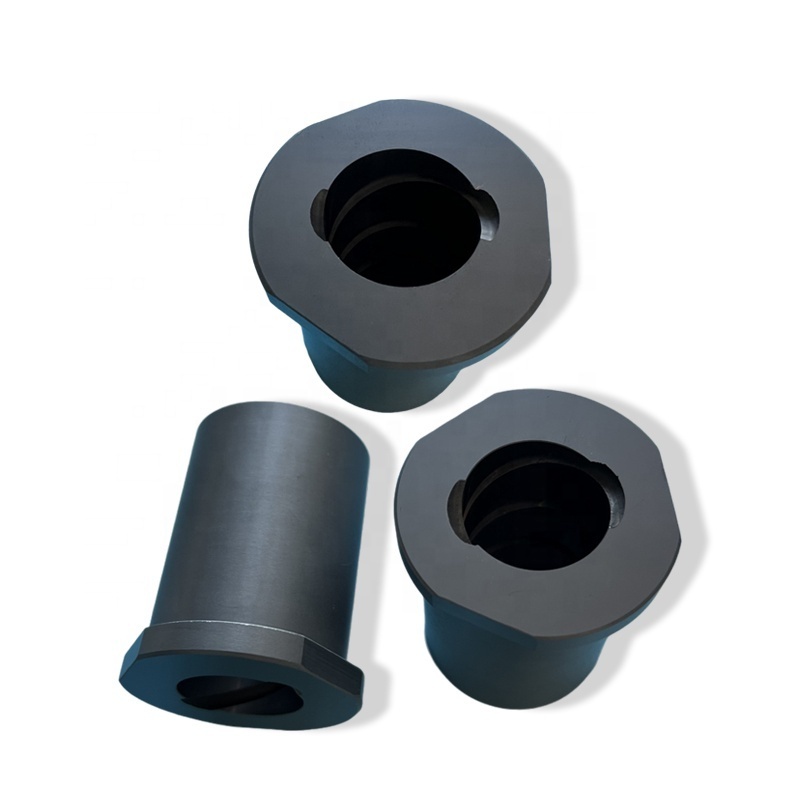

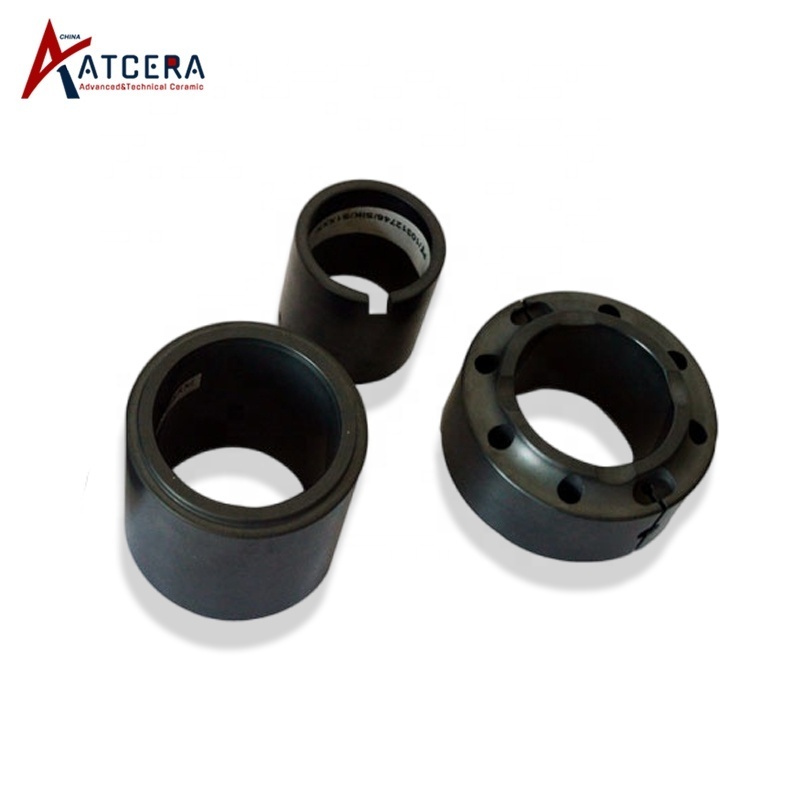

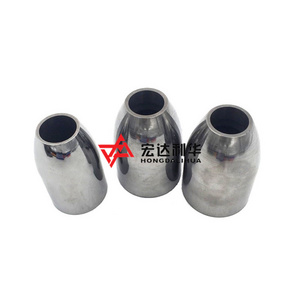

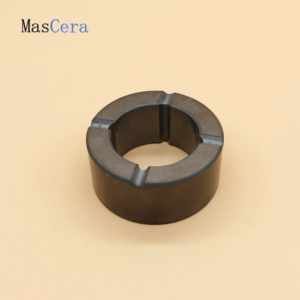

Product name:

-

Silicon Carbide Cylinder Liner

-

Shape:

-

As Drawing Requests

-

Maximum Use Temperature:

-

1750℃

-

Compressive Strength:

-

3900Mpa

-

Density:

-

>3.2g/cm3

Quick Details

-

Material:

-

Silicon Carbide

-

Place of Origin:

-

Hunan, China

-

Model Number:

-

Atcera

-

Brand Name:

-

Atcera

-

Product name:

-

Silicon Carbide Cylinder Liner

-

Shape:

-

As Drawing Requests

-

Maximum Use Temperature:

-

1750℃

-

Compressive Strength:

-

3900Mpa

-

Density:

-

>3.2g/cm3

The silicon carbide sleeve is mainly used to protect the motor shaft or related rotating parts, reduce friction and wear, and improve the efficiency and life of the motor. Due to its high hardness and wear resistance, silicon carbide bushings can withstand operation under high loads and high temperature environments while maintaining stable performance.

The silicon carbide sleeve also has excellent thermal conductivity, which can effectively transfer the heat inside the motor and maintain the stable operation of the motor.

|

Ceramic Properties

|

|

|

|

|

|

|

||||||

|

Item

|

Unit

|

99%Al2O3

|

ZrO2

|

AIN

|

Si3N4

|

SiC

|

||||||

|

Density

|

g/cm3

|

3.9

|

6

|

3.23

|

3.2

|

3.2

|

||||||

|

Gas permeability

|

|

0

|

0

|

0

|

0

|

0

|

||||||

|

Water Absorption

|

|

0

|

0

|

0

|

0

|

0

|

||||||

|

Flexural Strength

|

Mpa

|

340

|

1000

|

400

|

1000

|

/

|

||||||

|

Compressive Strength

|

Mpa

|

3600

|

3000

|

3500

|

3600

|

2000

|

||||||

|

Modulus of Elasticity

|

Gpa

|

380

|

200

|

380

|

300

|

410

|

||||||

|

Impact Resistance

|

Mpa.m1/2

|

5.1

|

6

|

4

|

7

|

4

|

||||||

|

Vickers Hardness

|

HVO.5

|

1650

|

1200

|

1650

|

1600

|

2000

|

||||||

|

Thermal Conductivity

|

W/mk

|

27

|

< 2

|

260

|

30

|

70

|

||||||

|

Highest Application Temperature

|

°C

|

1750

|

1050

|

2200

|

1300

|

1300

|

||||||

|

Volume resistivity(20°C)

|

Ohm/cm2

|

>1014

|

>1013

|

>1014

|

>1014

|

>1015

|

||||||

|

Dielectric breakdown strength

|

KV/mm

|

25

|

17

|

25

|

20

|

20

|

||||||

|

Dielectric Constant

|

1MHZ

|

9.5

|

30

|

8

|

9

|

/

|

||||||

|

Thermal Expansion(25-1000°C)

|

1X10-6/℃

|

5.4-8.3

|

10

|

4.0-6.0

|

3

|

4.5

|

||||||

Hunan Atcera CO. Ltd. has been deeply engaged in the field of advanced ceramics for 12 years, and has production experience of more than 2000 precision ceramic products. We focus on the material of alumina ceramics, aluminum nitride ceramics, zirconia ceramics, silicon carbide ceramics, boron carbide ceramics, silicon nitride ceramics, boron nitride ceramics, quartz, etc., and aim to provide you with advanced ceramics one-stop service.We have been offering our products and services to our clients from more than 100 countries or regions.

Hot Searches