1. Raw materials: stainless steel/copper strip/galvanized strip/aluminium strip/cold rolling

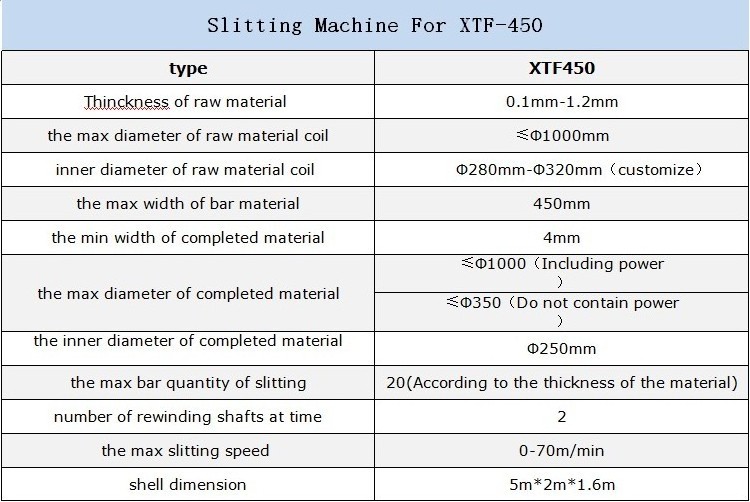

2. Slitting strip thickness: 0.1mm~1.2mm

3. Maximum feed width: <450mm

4. Maximum Outer Diameter of Raw Material: <1000mm

5. Raw material inner diameter: 280mm~320mm (customizable)

6. Weight of raw materials: <1000Kg

- Product Details

- {{item.text}}

Quick Details

-

Name:

-

High precision galvanized steel coil winding slitting machine price

-

Usage:

-

Steel Coil Slitting Machine

-

Function:

-

Slitting

-

Raw material:

-

steel/aluminum/copper/stainless steel

-

Certification:

-

ISO9001

-

Use:

-

Automatic Decoiler

-

Speed:

-

70m/min

-

Net Weight:

-

3T

Quick Details

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

XINTAI

-

Weight (KG):

-

3500

-

Name:

-

High precision galvanized steel coil winding slitting machine price

-

Usage:

-

Steel Coil Slitting Machine

-

Function:

-

Slitting

-

Raw material:

-

steel/aluminum/copper/stainless steel

-

Certification:

-

ISO9001

-

Use:

-

Automatic Decoiler

-

Speed:

-

70m/min

-

Net Weight:

-

3T

Baoji Xin Tai Precision Equipment Manufacturing CO., LTD,

built in 1995, mainly working on researching, development and production of electron, metallurgy and special grinding equipment. It Produces all kinds of equipment for slitting material used for electrolysis and capacitor, such as: aluminum foil, copper foil, metal foil, paper slitting, foil slitting, membrane cutting and metal bar material slitting.

we hope to honestly cooperate with all friends in different world and develop together.

Product Application

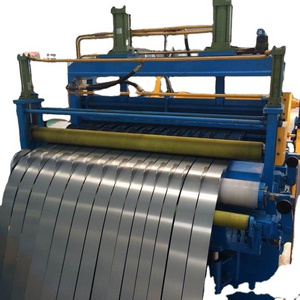

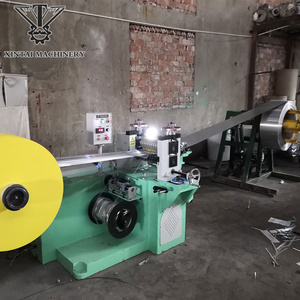

The precision cutting machine is used to cutting stainless steel, copper strip, galvanized strip, aluminum strip, cold rolled metal. The equipment characteristics are operation convenient, high-quality slitting, high-using rate or material, and step-less adjustment of slitting speed.

Main Features

1. This machine is suitable for longitudinal shearing of rolling metal strips. It has the characteristics of convenient operation, high cutting quality, high material utilization rate and stepless adjustment of cutting speed.

2. Product warranty period is one year, non-human problems, free spare parts are provided during the warranty period, and the supplier is responsible for the lifelong maintenance of equipment.

3. Equipment color: black and white (customizable)

4. Date of production: 25 days

5. Support overseas after-sales service.

Raw material parameters

Finished product parameters

1. Material width of finished product: 4mm~500mm

2. Outer diameter of finished coil: <1 000 mm

3. Inner diameter of finished coil: 250mm (customizable)

4. Number of sliced strips: 25 (according to the thickness of the sliced material)

5. Width tolerance of finished product: ±0.02mm

Device parameters

2. Equipment speed: 0-80m/min

3. Equipment capacity: 15.5KW

4. Coverage of equipment L*W*H:5m*2m*1.6m

5. Equipment weight: 3T

Electrical parameters

1. Inverter: Audi (China)

2. Intelligent Voltmeter: French School (China)

3. Intermediate relay: Omron (Japan)

4. Electrical Switching Components: Zhengtai (China)

5. Power supply for equipment: three fires and one place, AC380V, 50HZ

6. Motor: Wuxi Pioneer

7. Reducer: Wuxi Keyide

Pre-Sales Service

After-Sales Service

|

Packaging

|

|

|

|

Size

|

5m (L) * 2m (W) *1.6m (D)

|

|

|

Weight

|

3.5T

|

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|

Production workshop

In our company, skilled men are more, all kinds of methods of production process are complete, product quality guarantee system and test system are complete. As per user requirements, we produce special equipment of different types. Abundant technology and advanced management idea constitute serious quality guarantee system and strong researching and devolvement ability.