In accordance with CO2 foaming process environment, we design and develop single-screw secondary extruder with 2-way and high cooling efficiency. Single-screw design has good effect on large cooling area coverage. Its process multi-stage kneading low shear heating, melting temperature homogenizer,low-speed but high throughput 500 kg/h speed only 3.6 rpm.

Automatic temperature control system with multiple points on integrated design of 2-ways heat exchange and with a special design of the secondary efficient cooling extruder screw, it is able to regional peer-to-peer rapid cooling heat exchange. According to the set process parameters PID self-tuning adjustment, its precise temperature control can be within±1℃

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong

-

Weight:

-

35000 KG

-

after-service:

-

online support

-

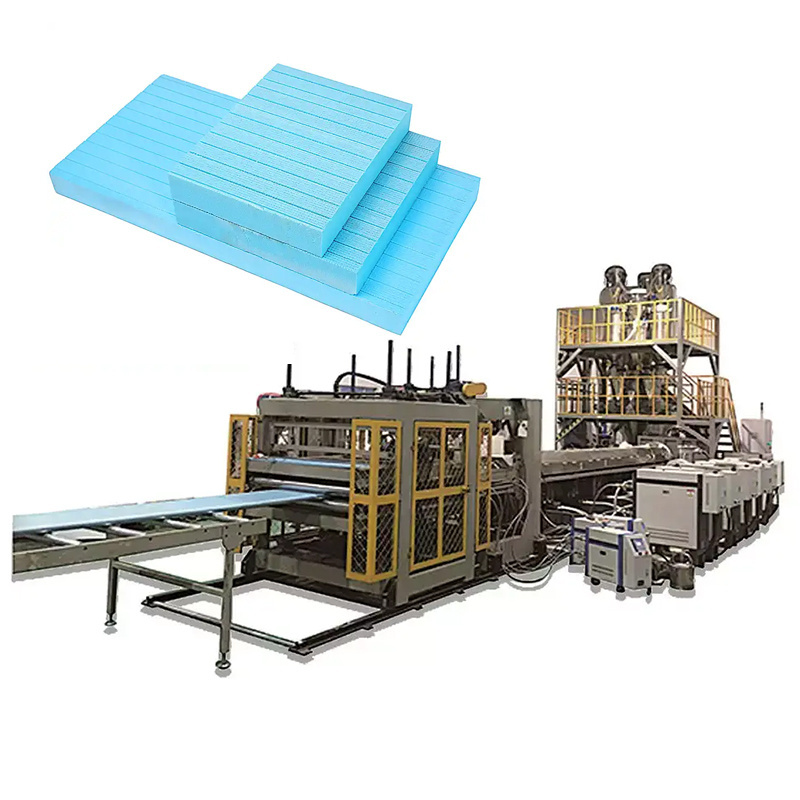

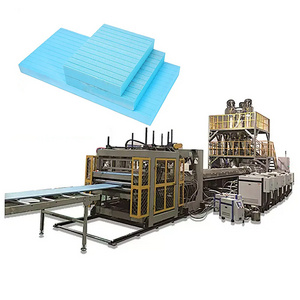

Product Name:

-

EPS Foam Plate Making Machine

-

Name:

-

Eps Block Making Machine

-

Raw material:

-

Polystyrene Granule(GPPS)

-

Keywords:

-

Foam Machinery

-

Foam Type:

-

Second Foaming

-

Finished products:

-

xps foam sheet

-

Function:

-

Foam Maker

-

Color:

-

Blue

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

34:1

-

Screw Speed (rpm):

-

50 rpm

-

Place of Origin:

-

Shandong

-

Weight:

-

35000 KG

-

after-service:

-

online support

-

Product Name:

-

EPS Foam Plate Making Machine

-

Name:

-

Eps Block Making Machine

-

Raw material:

-

Polystyrene Granule(GPPS)

-

Keywords:

-

Foam Machinery

-

Foam Type:

-

Second Foaming

-

Finished products:

-

xps foam sheet

-

Function:

-

Foam Maker

-

Color:

-

Blue

Machine Parameter

|

model

|

unit

|

DYXPS-75/200

|

|

DYXPS-85/250

|

|

DYXPS-95/300

|

|

|||||

|

screw diameter

|

mm

|

Φp75/200

|

|

Φp85/250

|

|

Φp95/300

|

|

|||||

|

heating power

|

kw

|

70

|

72

|

80

|

88

|

90

|

100

|

|||||

|

driving motor power

|

kw

|

132

|

90

|

200

|

110

|

280

|

132

|

|||||

|

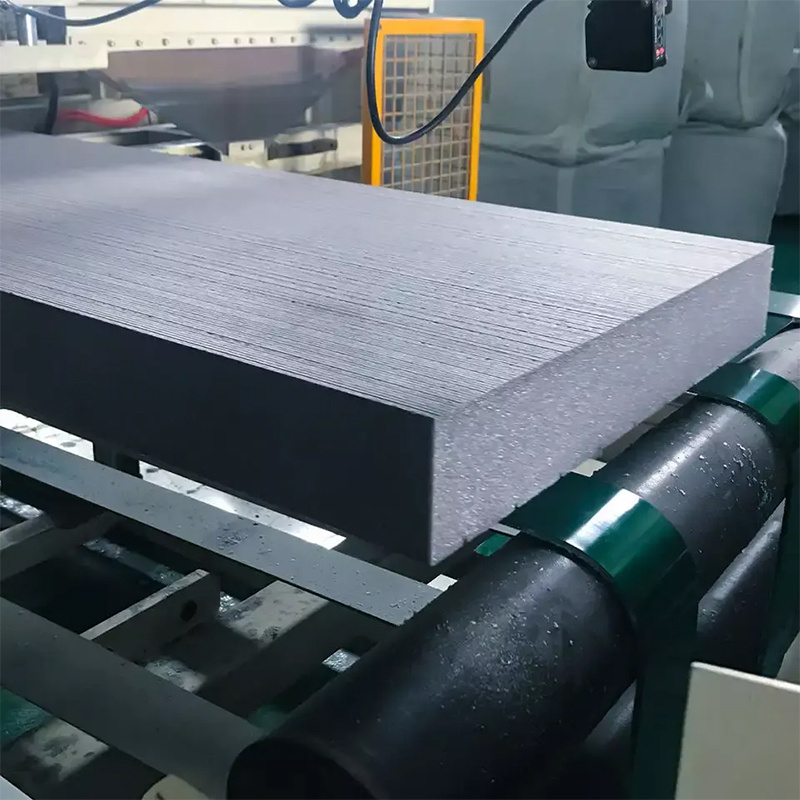

thickness of board

|

mm

|

20-120

|

|

20-130

|

|

40-140

|

|

|||||

|

width of board

|

mm

|

600 1200

|

|

600 900 1200

|

|

600 900 1200

|

|

|||||

|

length of board

|

mm

|

1200 1250 2450 2500

|

|

|

|

|

|

|||||

|

capacity

|

kg/h

|

550-600

|

|

750-800

|

|

850-1200

|

|

|||||

|

total power

|

kw

|

520

|

|

620

|

|

720

|

|

|||||

|

oversize(L*W*H)

|

m

|

60*10*5

|

|

62*11*5

|

|

64*12*5

|

|

|||||

|

total weight

|

T

|

35

|

|

38

|

|

40

|

|

|||||

DETAILED IMAGES

Five groups of automatic weight feeding system

1. Adopt multi component dynamic automatic continuous measurement, vacuum automatic feeding;

2.High accuracy can achieve 0.5% of the dynamic accuracy, stable state of up to 0.2%;

3.The average of each component power consumption is only 0.2KW/h;

4.Meter can handle the material from the state can be divided into pellets, powder;

2.High accuracy can achieve 0.5% of the dynamic accuracy, stable state of up to 0.2%;

3.The average of each component power consumption is only 0.2KW/h;

4.Meter can handle the material from the state can be divided into pellets, powder;

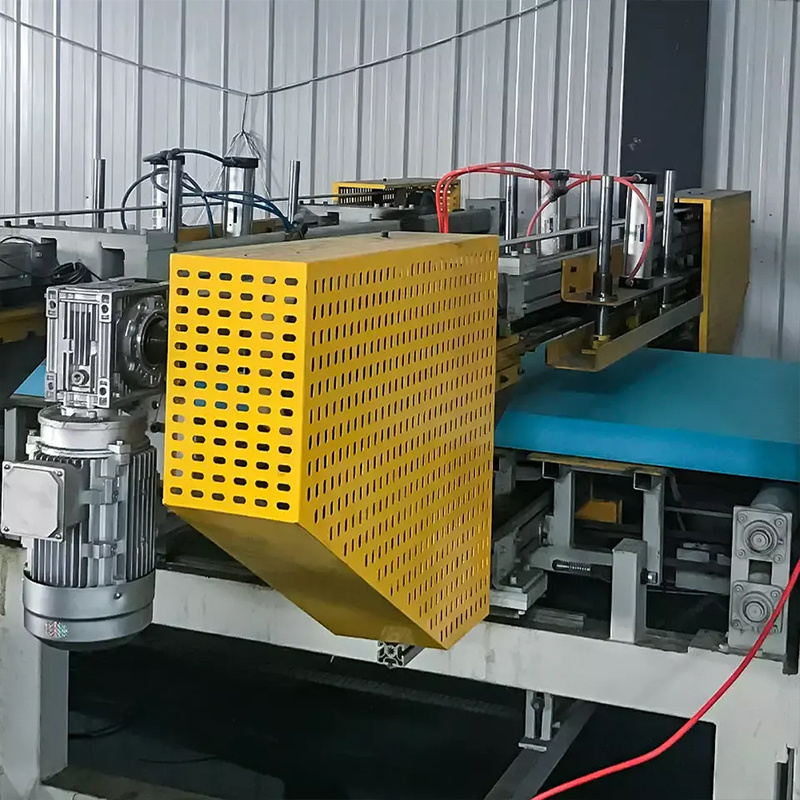

75 parallel and same direction twin screw extruder

1. screw body processing by the horizontal machining center one-piece complete, to ensure the installation accuracy;

2. screw design according to the required amount of CO2 foaming process tailored, adopt high carbon high alloy ledebrite ;

3.with a stainless steel protective cover with radiating holes, to prevent accidental contact scald;

4.high pressure four position leak proof high pressure switch ;

2. screw design according to the required amount of CO2 foaming process tailored, adopt high carbon high alloy ledebrite ;

3.with a stainless steel protective cover with radiating holes, to prevent accidental contact scald;

4.high pressure four position leak proof high pressure switch ;

Horizontal cutting machine

1.Horizontal cutting knife, double knife double cut design;

2.Horizontal mobile motor with 1.5 *2 KW;

3.Longitudinal movement of the track drive;

4.The cutting length is controlled by a photoelectric or contact type switch;

5.Vacuum cleaner port PLC programming control;

2.Horizontal mobile motor with 1.5 *2 KW;

3.Longitudinal movement of the track drive;

4.The cutting length is controlled by a photoelectric or contact type switch;

5.Vacuum cleaner port PLC programming control;

CO2 foaming agent automatic injection system

1.High pressure and low temperature metering pump station

2.Mass flow calculation system ;

3.Automatic cycle constant liquefaction device;

4.Liquid static mixing device;

5.Stainless steel high pressure anti-corrosion connection, pipe fittings ;

6.Computer control system ;

7.Low temperature transport system ;

8.Buffer high-pressure and low temperature tank (with CO2/ethanol) ;

2.Mass flow calculation system ;

3.Automatic cycle constant liquefaction device;

4.Liquid static mixing device;

5.Stainless steel high pressure anti-corrosion connection, pipe fittings ;

6.Computer control system ;

7.Low temperature transport system ;

8.Buffer high-pressure and low temperature tank (with CO2/ethanol) ;

Stacking unit

1.stack size: 1200-2400mm*600mm*900mm ;

2.Lift motor power: 3kw ;

3.Transmission motor power: 0.37kw ;

4.Speed control mode: frequency conversion speed ;

2.Lift motor power: 3kw ;

3.Transmission motor power: 0.37kw ;

4.Speed control mode: frequency conversion speed ;

Mold temperature cotroller

The heat conduction medium with high heat conduction is used to control the temperature rise of the die in a very short time.

After setting the heat balance temperature, the mold temperature can automatically control its temperature within the minimum error and maintain the fixed value.

After setting the heat balance temperature, the mold temperature can automatically control its temperature within the minimum error and maintain the fixed value.

FAQ

Q:How much is the biggest throughput of your machine?

A:Our DYXPS-75/200 can yield 550-600kg/hr.

Q:What’s the thickness range of the boards?

A:Our full series of lines can produce from 10-200mm thickness directly. However, each model has its own suitable

range, therefore thickness range of targeting market is the key determining factor when selecting machine.

Q:What is the width range?

A:The international standard width is 600mm, some countries have 1200mm and 900mm width. In principle, any width

can be produced by changing die or adding slitting machine.

Q:how can we guarantee quality?

A: Always a pre-production sample before mass production;

Always final Inspection before shipment

Q: What should we prepare except material?

A: You should prepare workshop, water line, electric line, compress air (if you need, we can help you buy air compressor). We can supply workshop layout drawing according to your workshop.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Longkou city, Shandong province, you can fly to Yantai or Qingdao airport, Yantai airport is nearer than Qingdao airport.

A:Our full series of lines can produce from 10-200mm thickness directly. However, each model has its own suitable

range, therefore thickness range of targeting market is the key determining factor when selecting machine.

Q:What is the width range?

A:The international standard width is 600mm, some countries have 1200mm and 900mm width. In principle, any width

can be produced by changing die or adding slitting machine.

Q:how can we guarantee quality?

A: Always a pre-production sample before mass production;

Always final Inspection before shipment

Q: What should we prepare except material?

A: You should prepare workshop, water line, electric line, compress air (if you need, we can help you buy air compressor). We can supply workshop layout drawing according to your workshop.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Longkou city, Shandong province, you can fly to Yantai or Qingdao airport, Yantai airport is nearer than Qingdao airport.

Why Choose Us

Hot Searches