- Product Details

- {{item.text}}

Quick Details

-

Viscosity:

-

paste mPas(25°C)

-

Density:

-

1.65-1.75 g/cm3(25°C)

-

Tackfreetime:

-

10-20 min(25°C,55%RH)

-

dielectricstrength:

-

≥20 kV/mm(25°C)

-

hardness:

-

55-65 Shore A

-

thermalcoefficient:

-

0.8 W/mK

-

expansioncoefficient:

-

210 μm/(m,°C)

-

water absorption:

-

0.01-0.02 24h,25°C,%

-

elongation at rupture:

-

≥2.8 Mpa

-

tensilestrength:

-

≥2.5 Mpa

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

jorle

-

Model Number:

-

zr716

-

Viscosity:

-

paste mPas(25°C)

-

Density:

-

1.65-1.75 g/cm3(25°C)

-

Tackfreetime:

-

10-20 min(25°C,55%RH)

-

dielectricstrength:

-

≥20 kV/mm(25°C)

-

hardness:

-

55-65 Shore A

-

thermalcoefficient:

-

0.8 W/mK

-

expansioncoefficient:

-

210 μm/(m,°C)

-

water absorption:

-

0.01-0.02 24h,25°C,%

-

elongation at rupture:

-

≥2.8 Mpa

-

tensilestrength:

-

≥2.5 Mpa

Description:

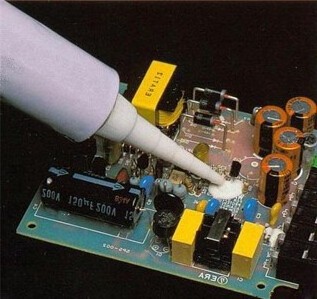

Z R716 silicon heat conductive glue for electrics , it absorb the moisture in the air at room temperature curing neutral organic silicon sealing material, not heating curing. It for the vast majority of material, have good adhesive sealing performance, protect electronic products in harsh conditions.

Characteristics After Cured :

1. Avoid moisture, dirt and other atmospheric composition

2. Relieve mechanical, thermal shock and vibration of mechanical stress and tension.

3. Have excellent electrical insulating performance.

4. Outdoor aging, excellent service life up to 20-30 years

5. In the -60-260 °C it has stable mechanical and electrical properties

6. Fire resistance

7. Conductive performance

Technical parameters:

|

Before curing |

test item |

Testing standard |

unit |

value |

|

Color |

--- |

--- |

White or customer color |

|

|

viscosity |

GB/T 10247-2008 |

mPa · s ( 25 °C ) |

paste |

|

|

Dens |

GB/T 13354-92 |

g/cm 3 ( 25 °C ) |

1.65-1.75 |

|

|

Tack free time |

GB/T13477.5-2002 |

min ( 25°C ,55%RH ) |

10-20 |

|

|

After curing |

hardness |

GB/T 531.1-2008 |

Shore A |

55-65 |

|

thermalcoefficient |

GB/T 10297-1998 |

W/mK |

0.8 |

|

|

expansioncoefficient |

GB/T 20673-2006 |

μm/ ( m , °C ) |

210 |

|

|

water absorption |

GB/T 8810-2005 |

24h , 25 °C , % |

0.01-0.02 |

|

|

flame retardant rating |

GB/T 528-1998 |

% |

≥100 |

|

|

elongation at rupture |

GB/T 528-1998 |

Mpa |

≥2.8 |

|

|

tensile strength |

GB 6328-86 |

Mpa , iron/iron |

≥2.5 |

|

|

c |

GB/T 1693-2007 |

kV/mm(25°C) |

≥20 |

|

|

dielectric strength |

GB/T 1693-2007 |

( 1MHz ) (25°C) |

0.001 |

|

|

Loss factor |

GB/T 1693-2007 |

( 1MHz ) (25°C) |

2.8 |

|

|

permittivity |

GB/T 1692-92 |

( DC500V ) Ω· cm |

2.00E +14 |

Remark : All the above data come from 25 °C and 55% RH glue curing conditions after 7 days.

Packing Specification:

100ml/pc , 100pcs/carton

310ml/pc , 25pcs/carton

Storage and transportation:

1. Avoid light, heat preservation, sealed. (can be used as a non-dangerous goods preservation and transport);

2. shelf life: 6 months ( 25 °C ).