- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

92

-

Voltage:

-

220V

-

Current:

-

6.8KW

-

Rated Duty Cycle:

-

10%

-

Dimensions:

-

670*780*900mm

-

Use:

-

BGA disassembly and welding

-

PCB size:

-

10*10-500*450mm

-

PCB thickness:

-

0.5-8mm

-

Applicable chip:

-

0.3*0.6mm-80*80mm

-

Applicable chip minimum pitch:

-

0.15mm

-

Mounting accuracy:

-

±0.01mm

-

Temperature measuring interfaces number:

-

4

-

Chip magnification:

-

2-30 times

-

Upper heating power:

-

1200W

-

Lower heating power:

-

1200W

-

Control:

-

Touch Screen+Panasonic PLC

Quick Details

-

Applicable Industries:

-

SMT Production Line

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Max

-

Weight (KG):

-

92

-

Voltage:

-

220V

-

Current:

-

6.8KW

-

Rated Duty Cycle:

-

10%

-

Dimensions:

-

670*780*900mm

-

Use:

-

BGA disassembly and welding

-

PCB size:

-

10*10-500*450mm

-

PCB thickness:

-

0.5-8mm

-

Applicable chip:

-

0.3*0.6mm-80*80mm

-

Applicable chip minimum pitch:

-

0.15mm

-

Mounting accuracy:

-

±0.01mm

-

Temperature measuring interfaces number:

-

4

-

Chip magnification:

-

2-30 times

-

Upper heating power:

-

1200W

-

Lower heating power:

-

1200W

-

Control:

-

Touch Screen+Panasonic PLC

Product Overview

Description:

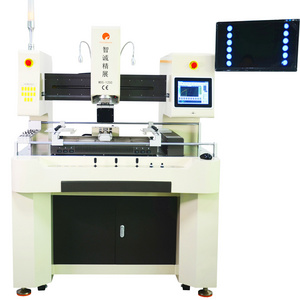

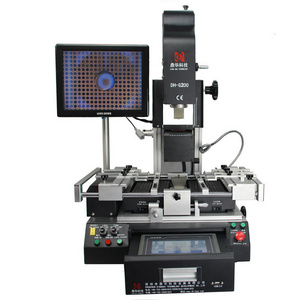

The BGA Rework Station

Disassembly and welding of all kinds of wafer packaging

(

Application for LCD TV、game machine、STB、 vehicle data recorder、 server、 mobile phone、 security product、industrial control motherboard, SMT processing and so on..

)

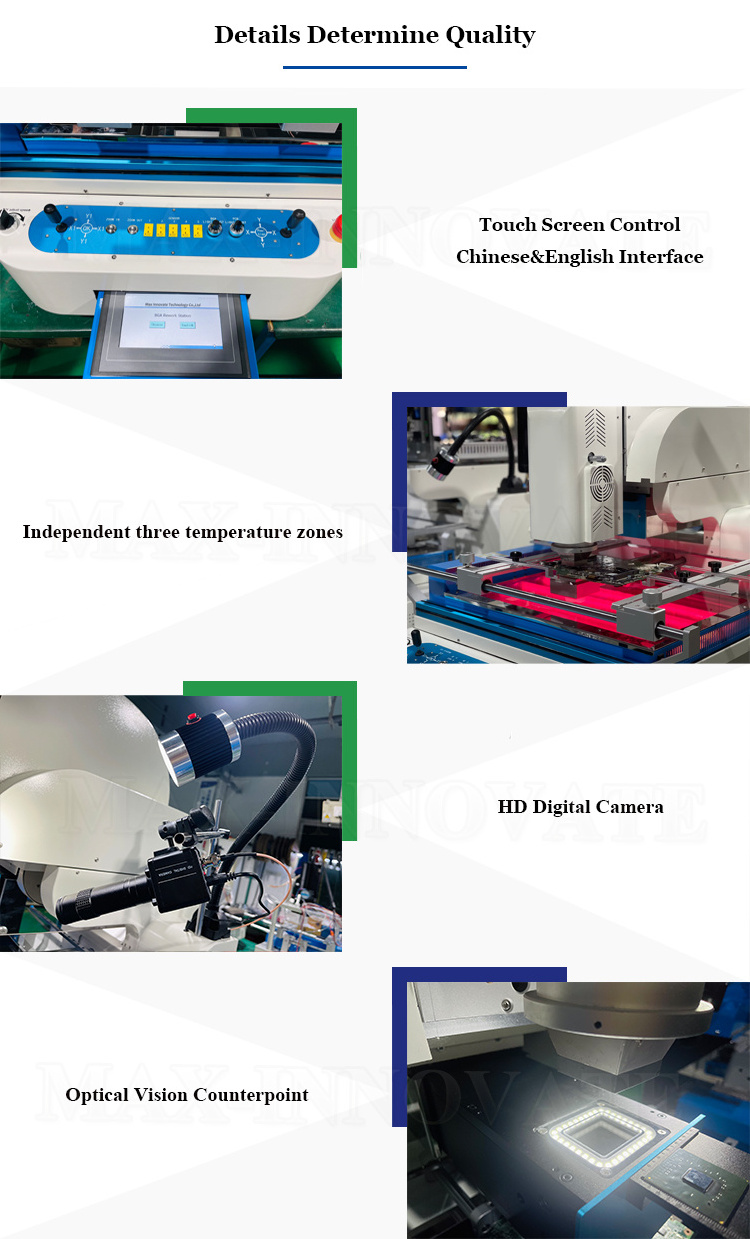

1. Touch screen +Panasonic PLC control, heating time, heating temperature, heating speed, cooling time, early warning, vacuum time,etc. can set on the touch screen, easy operation;

2. Three temperature zones are independently , and each temperature zone can be independently set for heating temperature, heating time, and heating slope; six heating temperature sections, which simulate the reflow soldering heating method, can be set [ preheat, heat preservation, temperature rise, welding, return Welding, cooling ];

3. Automatic feeding, suction and unloading ; it can automatically identify the center position of the chip when it is aligned;

4.Multi-function mode selection, there are four modes [ welding, unloading, mounting, manual ], which can realize automatic and semi-automatic functions, and better meet the various needs of customers;

5. High-precision K-type thermocouple closed-loop control imported from the United States is selected, welding temperature accuracy is within ± 1 ℃;

6.Adopts imported optical alignment system and is equipped with 15-inch high-definition display; high-precision micrometer is used for X / Y / R axis adjustment ; to ensure the alignment accuracy is controlled at 0.01-0.02mm;

7.Upper heating head and the placement head are integrated; the machine is equipped with a variety of BGA heating air nozzles to better meet the needs of customers' various chips. The heating air nozzle is easy to replace and special Requirements can be customized;

8.Automation and high precision, for lead-free processes and double-layer BGA, QFN, QFP, capacitor resistance and other components rework ;

9.The side monitoring camera can be used to observe the melting of solder balls , which is convenient to determine the curve and welding effect; (This function is optional).

|

Model

|

|

RS-750

|

|

|

|||

|

Dimensions

|

|

670*780*900mm

|

|

|

|||

|

Total power

|

|

6800W

|

|

|

|||

|

Upper heating power

|

|

1200W

|

|

|

|||

|

Lower heating power

|

|

1200W

|

|

|

|||

|

Lower infrared heating power

|

|

4200W (2400W controlled)

|

|

|

|||

|

Power supply

|

|

AC 220V ± 10 50Hz

|

|

|

|||

|

Targeting

|

|

Optical lens + V-shaped card slot + laser positioning lamp for quick positioning

|

|

|

|||

|

Selection of electrical appliances

|

|

touch screen + temperature control module + PLC + stepper driver

|

|

|

|||

|

PCB size

|

|

10*10-500*450mm

|

|

|

|||

|

Temperature measuring interfaces

|

|

4

|

|

|

|||

|

Chip magnification

|

|

2-30 times

|

|

|

|||

|

PCB thickness

|

|

0.5-8mm

|

|

|

|||

|

Applicable chip

|

|

0.3*0.6mm-80*80mm

|

|

|

|||

|

Applicable chip minimum pitch

|

|

0.15mm

|

|

|

|||

|

Mounting maximum load

|

|

500G

|

|

|

|||

|

Mounting accuracy

|

|

±0.01mm

|

|

|

|||

|

Optical alignment lens

|

|

The electric drive can move back and forth, left and right, and absolutely avoid dead angle

|

|

|

|||

|

Weight

|

|

Approx.92Kgs

|

|

|

|||

Products Description

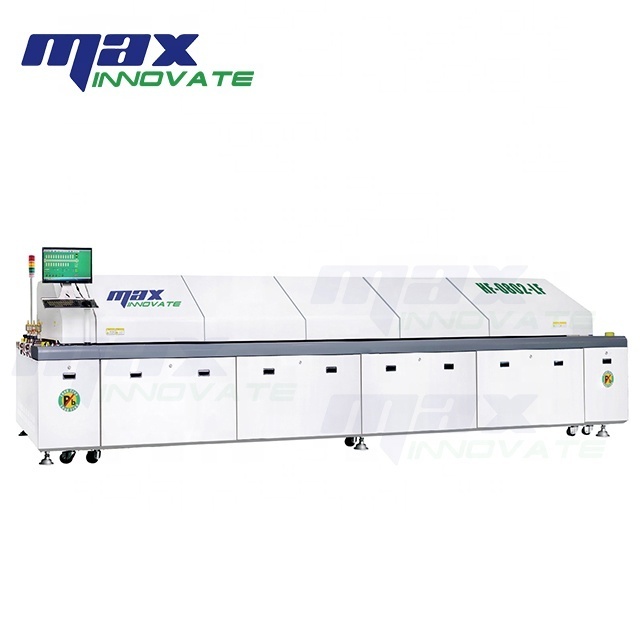

Related Products

All kinds SMT&DIP Machine,welcome inquiry and discuss with us!

Packing&Shipping

Packing Details :Plywood case, for export!

Port:Shenzhen

Delivery Details :7-10days

Port:Shenzhen

Delivery Details :7-10days

Max

Machine from the production to packaging to transportation, have strict quality control, use high-quality materials, make the best products, so that every customer satisfaction.

Accept various modes of transportation, fast delivery time!

Our Company

Max Innovate Technology (ShenZhen) Ltd

is the leading PCB factory solution provider in China,offering professional machine and assembly line accessories as the DIP welding equipment series, SMT welding equipment series and SMT&DIP whole line series over 20 years.Such as Reflow oven,Wave soldering machine,DIP soldering machine,Curing oven,Pick and place machine,PCB printer,Glue dispenser,PCB coating machine,Mixer,PCB cutter,SMD taping machine,SMD chips counter,SMT handling machine(PCB conveyor,PCB loader unloader,PCB buffer,PCB reject conveyor,PCB inverter,PCB stacker and so on).

Certifications

Highest quality philosophy

We deliver the highest quality for your production facility. For us this assertion is a permanent element of our company

philosophy. The satisfaction of our clients is our measure of success, and it runs through every detail of our production.

Quality Policy

Achieve total customer delight through continual improvements, innovations and cost reduction in design & manufacturing of SMT automatic Equipment. We shall commit to satisfy applicable requirements and continually improve our quality management system.

Excellent quality

Our systems are regularly certified to ISO standards, ensuring that every single part meets its requirements to perfection. Max has been distinguished for many years by strict quality criteria as a specialist welding facility; thanks to its excellent metal processing it provides the best possible conditions. We also plan and design all our machines with CE conformity in accordance with specified machinery directives.

We deliver the highest quality for your production facility. For us this assertion is a permanent element of our company

philosophy. The satisfaction of our clients is our measure of success, and it runs through every detail of our production.

Quality Policy

Achieve total customer delight through continual improvements, innovations and cost reduction in design & manufacturing of SMT automatic Equipment. We shall commit to satisfy applicable requirements and continually improve our quality management system.

Excellent quality

Our systems are regularly certified to ISO standards, ensuring that every single part meets its requirements to perfection. Max has been distinguished for many years by strict quality criteria as a specialist welding facility; thanks to its excellent metal processing it provides the best possible conditions. We also plan and design all our machines with CE conformity in accordance with specified machinery directives.

Customer Photos

MAX

exporting our products to valuable customers in over 30 countries throughout the Europe, America, the Mid-East, Southeast Asia,Africa, etc.

Experienced R&D, production, sales and multi-core technologies make us one of the leaders of the SMT&DIP machine.

We not only provide SMT&DIP Line equipments, what's more, we also provide technical support and services, Besides we give our customers more reasonable and professional suggestions.We have already helped many customers to establish factories in LED, TV,Phone, Router, EMS and other filed around the world;

We devote to serve customers and meet all of their diversified requirments with stable technical level, innovative design concept,precise manufacturing process, reasonable price and customer first after-sales system

Experienced R&D, production, sales and multi-core technologies make us one of the leaders of the SMT&DIP machine.

We not only provide SMT&DIP Line equipments, what's more, we also provide technical support and services, Besides we give our customers more reasonable and professional suggestions.We have already helped many customers to establish factories in LED, TV,Phone, Router, EMS and other filed around the world;

We devote to serve customers and meet all of their diversified requirments with stable technical level, innovative design concept,precise manufacturing process, reasonable price and customer first after-sales system

Why Choose Us

Hot Searches